Capri Blue PPGI Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

PPGI Coil1.Common polyester paint

2.50-150g/m2 dipped layer

3.2 Coating 2 Baking process

4.Long life span

PPGI Coil

Brief Introduction

1. PPGI Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for PPGI Coil is HDG steel. The finish coats of PPGI Coils can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

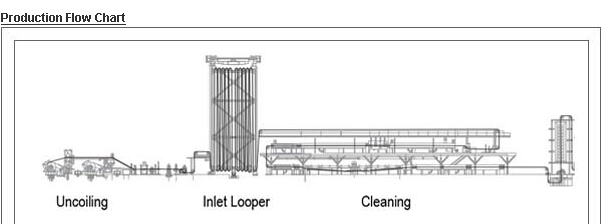

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the PPGI Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The PPGI Coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

- Q:How does steel pipe threading for plumbing applications work?

- Steel pipe threading for plumbing applications involves the process of cutting threads onto the ends of steel pipes to create a secure and leak-proof connection. This is typically done using a threading machine that rotates the pipe while a cutting die is applied to create the threads. The cutting die removes metal from the pipe, forming helical grooves, which align with the threads on fittings or other pipes. The threaded ends can then be joined together using pipe fittings or couplings, ensuring a tight and durable connection in plumbing systems.

- Q:What are the applications of steel in the pharmaceutical industry?

- Steel is widely used in the pharmaceutical industry for various applications, including the manufacturing of equipment like storage tanks, pressure vessels, and piping systems. It is also used in the construction of cleanrooms and laboratories due to its durability, corrosion resistance, and easy cleanability. Furthermore, steel is utilized in the production of pharmaceutical packaging materials such as vials, syringes, and needles. Its strength and inertness make it an ideal choice for ensuring product safety and integrity.

- Q:How is steel tubing used in the manufacturing of automobile exhaust systems?

- Steel tubing is commonly used in the manufacturing of automobile exhaust systems due to its durability, heat resistance, and ability to withstand high temperatures. It is used to create the exhaust pipes, which transport the exhaust gases from the engine to the rear of the vehicle. Additionally, steel tubing is also utilized for the construction of various components within the exhaust system, such as mufflers and catalytic converters, to ensure proper functioning and longevity of the system.

- Q:What are the different methods of testing the quality of steel products?

- There are several methods of testing the quality of steel products, including destructive and non-destructive testing methods. Destructive testing involves subjecting the steel to extreme conditions, such as tension, compression, or bending, to determine its mechanical properties and strength. Non-destructive testing methods include visual inspection, ultrasonic testing, magnetic particle testing, and radiographic testing, which allow for the detection of defects or irregularities in the steel without causing any damage. These testing methods help ensure that steel products meet the required quality standards and are fit for their intended applications.

- Q:How is steel used in the manufacturing of material handling equipment?

- Steel is commonly used in the manufacturing of material handling equipment due to its strength, durability, and versatility. It is used to create the frames, supports, and components of various equipment such as forklifts, cranes, conveyors, and storage racks. Steel's high tensile strength allows these equipment to handle heavy loads and withstand the rigors of daily use in industrial environments. Additionally, steel can be easily shaped, welded, and machined, making it an ideal choice for creating complex and customized designs required in material handling equipment.

- Q:What are the different types of steel gratings and stair treads available?

- There are several different types of steel gratings and stair treads available, including welded steel bar grating, press-locked bar grating, riveted grating, and fiberglass grating. Each type has its own unique characteristics and is suitable for different applications, whether it's for industrial, commercial, or residential use. These options offer various load-bearing capacities, slip resistance, durability, and aesthetic qualities, allowing for versatile and customized solutions for different projects.

- Q:What are the advantages of using steel in the manufacturing of security doors and windows?

- There are several advantages of using steel in the manufacturing of security doors and windows. Firstly, steel is an incredibly strong and durable material, providing a high level of protection against break-ins and forced entry. It is resistant to impact, bending, and tampering, making it an excellent choice for enhancing security measures. Secondly, steel offers excellent fire resistance, which is crucial in safeguarding a property and its occupants in case of a fire emergency. Additionally, steel is highly resistant to harsh weather conditions, such as extreme heat, cold, and moisture, ensuring that security doors and windows remain intact and functional for an extended period. Lastly, steel can be easily customized and designed to fit specific security requirements, offering flexibility and versatility in terms of design and aesthetics. Overall, the use of steel in manufacturing security doors and windows provides enhanced protection, durability, fire resistance, weather resistance, and customizable options.

- Q:How is steel pipe coated for corrosion protection?

- Steel pipe can be coated for corrosion protection using various methods, including applying a layer of zinc through hot-dip galvanizing, using epoxy or polyethylene coatings, or employing a combination of both. These coatings create a barrier between the steel and the surrounding environment, preventing corrosion and extending the lifespan of the pipe.

- Q:What are the safety precautions to be taken while handling steel products?

- When handling steel products, it is important to follow certain safety precautions. First, it is essential to wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots, to protect against potential injuries. Additionally, workers should be trained on proper lifting techniques to avoid strains or back injuries. It is crucial to use lifting equipment, such as cranes or forklifts, when dealing with heavy steel products to minimize the risk of accidents. Maintaining a clean and organized work area can prevent slips, trips, and falls. Finally, being aware of potential hazards, such as sharp edges or hot surfaces, and taking necessary precautions, such as using safety guards or handling tools, can ensure safe handling of steel products.

- Q:How are steel products used in the railway industry?

- Steel products are extensively used in the railway industry for various applications. Steel is commonly used for manufacturing railway tracks, train wheels, and various structural components of the railway infrastructure. Additionally, steel is used in the construction of railway cars, locomotives, and various equipment such as bridges, tunnels, and signaling systems. Its high strength, durability, and ability to withstand heavy loads make steel an ideal material for ensuring the safety and efficiency of the railway system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Capri Blue PPGI Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords