Cantilever Formwork with Great Performnce for Large Projects

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Cantilever Formwork Description

Cantilever Formwork is mainly used in the concrete pouring of pier, high buildings, and so on. The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical. A single pouring height is high and the finished concrete surface is perfect. Cantilever formwork has several types, the structure is similar, and has its own different characteristic. Can use them according to actual demand.

Main cantilever Formwork:PJ200 & PJ240,CB-240 etc.

Cantilever formwork is used in dams, piers, retaining wall and cooling tower etc. All the concrete side-pressure is borne by the anchors and the brackets. As there is no through-wall tie-rod, the concrete is very clean.

The formwork can be moved backward by 600mm for cleaning the formwork and fixing the reinforcing steel bar. Waler connector is used for connecting the form to ensure form alignment.

Form can be pushed to the already cast concrete by turning the adjust carriage to avoid concrete offset or leakage.The formwork can be moved freely as you request. The formwork can be inclined backward and forward. Max. angle: 30°. High standard elements can be widely used.

2. Main Features of Cantilever Formwork

-easy to assemble

-simple structure.

-easy, rapid and economical.

Economical and safe anchoring

The M30/D20 climbing cones have been designed especially for single-sided concreting using cantilever formwork in dam construction, and to allow the transfer of high tensile and shear forces into the still fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.

3. Cantilever Formwork Images

4. Cantilever Formwork Specifications

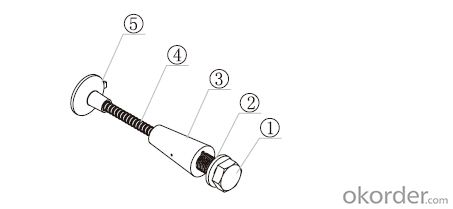

Anchor system

Anchor system is the most important supporting part. The system is made of five parts shown below. There into, tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusing after the concrete pouring.

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤Ancor plate D15

5.FAQ of Cantilever Formwork

1) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

2) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

- Q:What kind of scaffolding used in engineering construction

- Fastener type steel pipe scaffold for engineering building".

- Q:Now there are many kinds of scaffolding market, like what wheel buckle scaffolding, scaffolding, scaffolding, what.

- Now the company's scaffolding are bought, is assembled under the four small wheels mounted on the 4 legs. But do fire and water, the use of the machine is rented. Need to charge, and the car, you can move, will be raised to about 4.5 meters

- Q:The scaffold is 18 m long. A 650-N box sits 3.0 m from the left end. What is the tension in each wire? left wire = 520 N; right wire = 130 N left wire = 640 N; right wire = 210 N left wire = 195 N; right wire = 975 N left wire = 295 N; right wire = 1000 N can someone show me how to do this please :)

- Lets call left wire T1, right = T2 T1 = (200 x 9) + (650 x 15) = 11550 11550 = 18T1 11550/18 = 641.67 N T2 = (200 x 9) + (650 x 3) = 3750 3750 = 18T2 3750/18 = 208.33 N left wire = 640 N; right wire = 210 N

- Q:What is the height limitation of the standing braces in ringlock scaffolding system?

- Check the OSHA web site and search for scaffolding and then narrow the search. I bet you can find your answer there.

- Q:If the guillotine operator walked away from the scaffold where would he be headed?

- Rolling down the aisles.

- Q:I got it done MONTHS ago and the bar is so tight on it,i have space in it, like i can move the bar up and down..just i cant get it out and its beginning to hurt me if i sleep on the side its on.. advice please?

- Try wearing latex gloves (if you aren't allergic to latex.) This can hep you get a grip on the ends. You can go to your piercer and they will help you take it out. If you don't want to lose the piercing altogether, you can ask them to put small rings in it. This should ease and pressure and discomfort you are having.

- Q:It's not fixed to the building and it looks as though a heavy gust of wind would send it crashing down. How exactly does scaffolding stay up and not topple over?

- Well, it is attached to the building - not very strongly, but enough to keep it directly over the feet. The feet are adjusted to keep the part above them vertical so forces are straight down - easily achieved with a plumb bob on a string parallel to the pipes. Many scaffolding installations extend around a corner and with the diagonal bracing built in that provides stiffness. And scaffolding for working on a building is protected by the building, which blocks the air flow and slows it down from in the open air. Scaffolding towers, such as lighting at a concert or other special event (golf tournament) are guyed with wires/cables going out at an angle to anchors in the ground - these are often nearly invisible at any distance.

- Q:What is scaffolding pole, bar, scissors support?

- 1 divide the material according to the bar1) a single standard steel scaffolding steel pipe. It uses only one standard, such as steel tubular scaffolding, welded steel pipe using only 48 * 3.5.2, a variety of specifications of steel scaffolding, which consists of more than two kinds of different specifications of the steel pipe, such as door scaffolding3) steel based scaffolding. As to the steel pipe, and combined with other type of steel pieces composed of scaffolding, such as the channel has a base in the backwater or scaffolding, connecting steel scaffolding.

- Q:How much is the adjusting range of the scaffold of the bottom

- (3) is the key to the bottom assembly of bowl buckle scaffold, the assembly quality directly affect the overall quality in the installation bracket; the two layer horizontal bar, first check and adjust the level and the vertical frame is straight; secondly should check the level bar level, and by adjusting the vertical rod can be the adjustable base horizontal bar horizontal deviation less than L/400 (L is the horizontal rod length); inspect pole foot, ensure all pole under the pad, not vacant and loose; when the bottom shelf conforms to the erection requirements, check all the cuplok joint and locking, in the erection process at any time to check the the content, and make adjustment.(4) scaffording to strictly control the vertical rod vertical and horizontal rod level, the entire frame verticality deviation not more than h/500 (H is the height of the pole), but no more than 20mm; the horizontal rod level in accordance with the above provisions (3).

- Q:So a week ago today I got my industrial pierced. The pain was what I expected and afterwards it was very sore (as expected) however a week later it is a still rather sore and swollen and (I hate to be disgusting) quite crusty with dried blood/yellow stuff. I clean it everyday with salt water solution but I was just wondering if this was normal or should I take the piercing out?

- I#x27;m pretty sure it#x27;s normal make sure you use the proper cleanser for your ear. And make sure to clean it out as often as the piercer said to.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cantilever Formwork with Great Performnce for Large Projects

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords