Cantilever Formwork Used in The Concrete Pouring of Pier, High Buildings

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

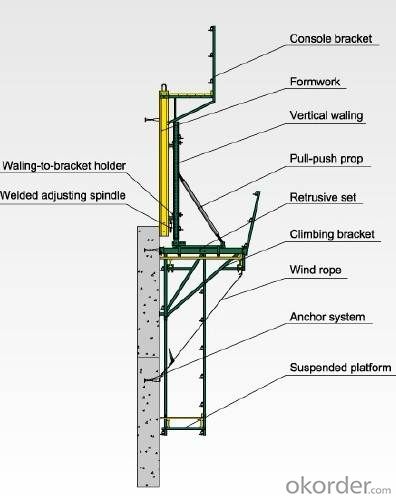

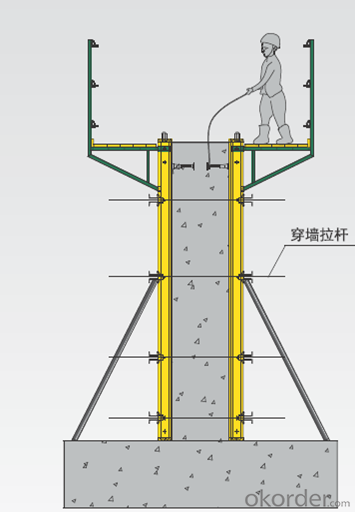

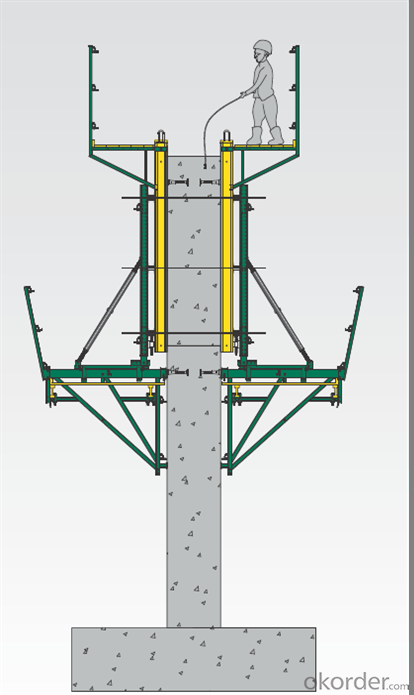

1. Structure of Cantilever Formwork Description

Cantilever Formwork is mainly used in the concrete pouring of pier, high buildings, and so on. The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical.

Main cantilever Formwork:PJ200 & PJ240,CB-240 etc.

2. Main Features of Cantilever Formwork

-easy to assemble

-simple structure.

-easy, rapid and economical.

3. Cantilever Formwork Images

4. Cantilever Formwork Specifications

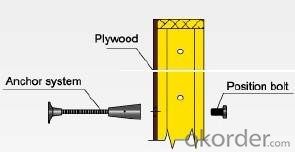

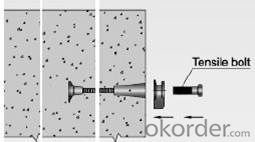

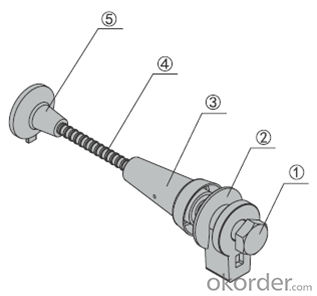

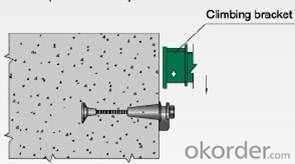

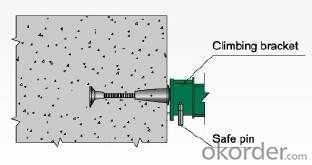

Anchor system

Anchor system is the most important supporting part. The system is made of five parts shown below. There into, tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusing after the concrete pouring.

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤Ancor plate D15

5.FAQ of Cantilever Formwork

1) What can we do for you?

.We can ensure the quality of the Cantilever Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

. Please feel free to customize.

2) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

3) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:What is the difference and connection between equipment manufacturing and machine building?

- When our company went to the training center of the Department of industrial engineering of Tsinghua University, the professor of Qinghua University told us about it. Equipment manufacturing industry is a general term for the equipment provided for the national economy and national security

- Q:How do the welding parts in the welding drawings of the machine parts indicate the technical requirements of the drawings?

- The whole circle of the triangle is welded as an angle weld, and the other is the outer circle with the same diameter as the two, so the butt joint is better to open the groove. Welding, for V type welding seam, and, technical requirements are generally, welding firm, no defects, welding smooth grinding, cleaning welding slag splash

- Q:What are the details of construction machinery parts in sand casting?

- (3) equipped with fittings, installation type air switch and air shower room installed in the furnace. (2) all kinds of vehicle tracks, transmitters, differential pressure and buttons are all materials other than the equipment body. (3) rotating filter network circulating water system for equipment, induction phase shifter, manhole and other various products embedded parts, clean bench, meter, scientific research and other functions of the machine, and pipeline safety device, railing, peep hole, ventilation air heater (1):

- Q:What is a door rack for a construction site? How high is it generally?

- Door scaffolding has not yet unified design and product standards, the products of different specifications, quality is inconsistent. Not only for construction units to use and management of great difficulties, is not conducive to the promotion of applications, but also to the construction safety risks. Therefore, it is necessary to organize and issue a unified standard for door scaffolding

- Q:Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Three is a business license, certificate of product quality, product quality inspection certificate. Business license is the legal provisions of some industries must be licensed, and handled by the competent department of the operating permit, such as tobacco monopoly license, drug business license, business license and other dangerous chemicals.

- Q:Where does Heilongjiang do the most construction machinery?

- All of the industry designated product range is roughly the same as that of China engineering machinery and other countries are also increased the railway engineering machinery, forklifts and industrial handling vehicles, decoration machinery, elevator, pneumatic tools and other industries.

- Q:Construction machinery production need to deal with what documents?

- At all levels of production safety responsibility system, mainly refers to: the legal representative of the safe production responsibility system; the responsible person in charge of safety production safety responsibility system; the technical director (Chief Engineer) production safety responsibility system; the safety department (Department) Changan production responsibility system; responsibility for production safety, the project manager; specifically (and) post safety responsibility system for production safety; construction technician (technician), safety production responsibility system; 8 class (Group) Changan production responsibility system; workers, production safety responsibility system. Departments responsible for production safety system, mainly in accordance with the functions of enterprises set up departments, the corresponding formulation of the responsibility system for safety in production.

- Q:What are the safety protection equipment, machinery and equipment, construction machinery and accessories for construction enterprises?

- Different types of work, security appliances are not the same. For buildings, the main safety helmets, safety nets, safety belts (San Bao), etc., for electrical operators, mainly insulated shoes, insulating gloves, insulation rod, insulation table, etc.

- Q:What are the mechanical drawing software?

- Personally, CAD is suitable for large machines or buildings, and CAXA is the real machine industry's universal software, and can also save drawings in various formats.

- Q:Definition of large mechanical equipment?

- A crane is a machine that cycles and intermittently moves. A work cycle includes fetching device from the extract to bring up the product, then move to the designated place down items, then reverse movement, the fetching device back in, for the next cycle.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cantilever Formwork Used in The Concrete Pouring of Pier, High Buildings

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords