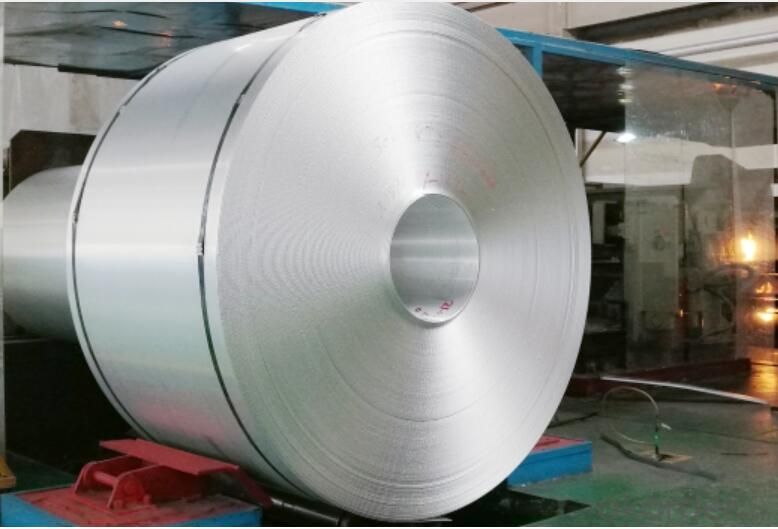

AA3104 H19 Aluminum Coil for Aluminium Can Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification

ALLOY:AA3104

TEMPER:H19

THICKNESS:0.26-0.29mm

WIDTH:700-1800mm

Special specification is available on customer's requirement

2.Description

3104 H19 aluminum alloy coil are the main alloy used in can body. It can be well used for thinning and stretching, with low earring ratio, good printing effect, reduced material consumption and batch purchase cost.

3.Pictures

4.Professional Quality Control Team

Inspect ingot before melting

Inspecting aluminium coil /foil stock before cold rolling

Inspecting finished goods before package

Inspecting package, loading before shipment

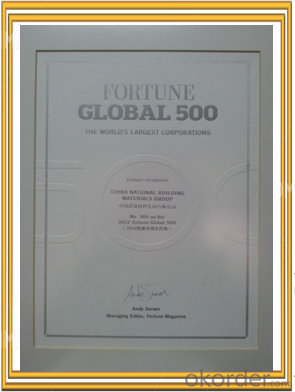

5.Certificates

- Q:Can you answer these questions?a)The mass of one mole of 27Al atoms is 26.9185 gGiven that the Avogadro constant equals 6.0225 x 1023 and the mass of one electron equals 9.1091 x 10-28 g, calculate the mass of one mole of 27Al3+ ions.b)Calculate the percentage difference between the mass of 27Al atoms and 27Al3+ ions, and use this to show why the mass of electrons are negligible in normal laboratory use of aluminium and other chemicals.Thank you!

- I do agree that attic insulation is an important factor but I am going to add to thatSince the bedroom is on the south side of the home and it is a small room, there is a good chance the exterior wall is getting really hot during the day and the heat may be getting through to the interior of the homeYou may need to find a way to shade the sun from the south wall i.ea large awning.

- Q:I know they're located in the quot;outermost shellquot; of the atom, but principal energy levels are synonomous to shellsDoes that mean they are located in the principal energy levels (n1, n2, etc)? But the first 7 principal energy levels contain 2, 8, 18, 32, 50, 72 and 98 electrons, respectively and elements can only have a maximum of 8 valence electrons, so that can't be the caseEach orbital may contain a maximum of 2 electrons so they can't be there eitherI am just having trouble visualizing where the valence electrons are within the atomHelp!?!?

- Does that imply they're located in the primary power stages? yes elements can most effective have a highest of 8 valence electrons, so that are not able to be the casenonetheless, it'sThe n 1 level can most effective keep 2 electrons (s subshell), so there are most effective two factors on the primary row of the periodic table: Hydrogen and HeliumHe has a full outer shell with 2 electronsThe n 2 stage can maintain as much as eight electrons (s and p subshells)There are 8 elements on row 2 of the periodic table, and the inert element Neon has 8 electrons in its full n 2 levelYour confusion traditionally starts at the n three stageIt has an s, p and d subshell retaining 2, 6 and 10 for a complete of 18 electrons altogetherSure that shell is indeed full with eight electrons, when the s and p subshells are fullThat aspect is ArgonYet there may be nonetheless a 3d shellWhile you get to the core of the periodic desk, you start filling that upRow four of the periodic table starts by way of filling up the 4s shellHowever then opening with Sc (aspect 21), you begin filling up 3d while you could have only 2 electrons in the 4sAt Zn (detail 30) the 3d shell is full, the n 3 shell is full, and then you definately begin filling up the 6 electrons in the 4p shellThere's nonetheless a 4d shell, however you don't start filling that until the center of the n 5 rowAnd there's a 4f shell which is being crammed from factors 57-70 which is after the commencing of the n 6 rowAt this factor my reminiscence of chemistry category breaks downI know this order has to with vigour, that 3d is larger vigour than 4s, and that 4d is better power than 5s, and that's why it fills afterI don't take into account why an aspect with 4s and 4p is inert though, although there's a 4d levelIt additionally has to do with vigour I suppose.

- Q:I know there are recycling centers that pay for aluminum and the suchBut I just have so much paper from college letters and bookletsalso a lot of old magazines I want to tossI'd just like to know if I could benefit from taking it all to a recycling center or someplacebesides helping the environment of which I love to do:P

- don't know any place that pays for paper i know the city of Erie collects paper for recycling this is the last week it needs bundled -next week just put the paper in a clear or blue bag and put it out with the trash for pickup - there is no more alternating blue bags and paper you can put it out at the same time in the same bag.- not sure about the county.

- Q:What are the differences between the cold aluminum and the plain foil used in packaging in the pharmaceutical industry? How do you distinguish them?

- Cold aluminum is cold formed aluminum foil, which is cold rolled. At this time, aluminum foil has a lot of stress.

- Q:Flan recipe.please translate into informal commands! it's really importantit doesn't have to be exact! you can dumb it down alot!Ingredients1 cup white sugar3 eggs1 (14 ounce) can sweetened condensed milk1 (12 fluid ounce) can evaporated milk1 tablespoon vanilla extractDirectionsPreheat oven to 350 degrees F (175 degrees C).In a medium saucepan over medium-low heat, melt sugar until liquefied and golden in colorCarefully pour hot syrup into a 9 inch round glass baking dish, turning the dish to evenly coat the bottom and sidesSet aside.In a large bowl, beat eggsBeat in condensed milk, evaporated milk and vanilla until smoothPour egg mixture into baking dishCover with aluminum foil.Bake in preheated oven 60 minutesLet cool completely.To serve, carefully invert on serving plate with edges when completely cool.PLEASE DO NOT USE ANY TRANSLATOR!!!!!

- Never used one but my guess would be like a bong, don't blow in to it.

- Q:I'm 18 and leaving for the Coast Guard at the end of this summerBefore that though my father is handing down his 12 ft aluminum starcraftIt has a 8 hp evinrude motor on it and I want to purchase an electric motorCould I have some guidance on how to or maybe some suggestions on a good budget electric (trolling) motor?

- If your mesh is too course to hold a thin set type addhesive,which it sounds like it probably is.Take a finer galvanized screen on top.Space the two apart at least 1/4.Make sure when you apply your thin set, that addhesive is pushed thru all the way to exsisting mesh.Clean off excess addhesive under the table before it dries completly.you might have to sponge underside with a very wet sponge.To make it all even through out.This will have alot of waste.But you will have one tough table.Seal as normal exterior tile after grout.

- Q:I used to buy this spice pack from Naturally India but stores near me no longer carry itSo sad!!! :(I found a spice mix called Meat Masala and these are the ingredients:corianderchillicumincassiapepperclovecardamoncarawaybay leafturmericgarlicfenugreek leavessaltstar anisenutmegmaceIS THIS SOMETHING I CAN USE TO MAKE TIKKA MASALA?(Creamy, tomato, onion curry sauce with sweet brown sugar and tofu or chicken - and maybe peas or spinach.)

- i think of that the newborn should not be overwhelmed by using various human beings by surprise whilst she comes residing houseHer father might desire to be the main important source of help and convenience to her the 1st few days she's residing house, and he or she might desire to learn how to recollect upon him maximum of alli'm particular it is going to be complicated for her on the initiating, yet 2 3 hundred and sixty 5 days olds are very resilient and it won't take her an prolonged mutually as to alterIf she's been abused or ignored interior the previous, it must be a sturdy theory to your brother to get her to a pediatrician sometime interior the close to destiny to debate ittake care and all the excellent to your loved ones!

- Q:Aluminum compounds with chemical formula if possible . . . Thanks.

- Al2O3 = Aluminium oxide AlPO4 = aluminium phosphate AlCl3 = aluminium Chloride etc

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA3104 H19 Aluminum Coil for Aluminium Can Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords