Calcium Silicate Boards Model 04 with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container pc

- Supply Capability:

- 35000Pcs/Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

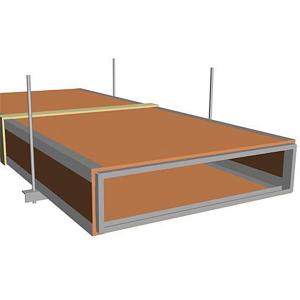

Description of Calcium Silicate Board:

A calcium silicate board is one of the new-type building materials recommended by the Ministry of Construction. It is a light, high-strength, fire-resistant and heat-proof material composed of scientific proportions of siliceous and calcareous materials, adulterated with appropriate amount of reinforcing materials, which are processed through pulping, molding, autoclave curing, drying and sandpaper polishing.

Main component:

Wood fiber, cement and so on. The nominal size is 1220*2440/1200*2400, with the maxium length 3.66m.

Physical performance of Calcium Silicate Board:

1.100% non-asbestos

2. Density: 1000-1200 KG/m3

3. Coefficient of thermal expansion: 0.24W/MK(JC/T54)

4. Bending strength: Over 13Mpa(GB/T7019-1997)

5. Linear expansion rate: 0.1%

6. Water absorption rate: Less 0.19%(GB/T7019-1997)

7. Water penetration rate: 0%

8. Water content: 10%

9. Incombustibility, A grade; Waterproof

10. Radioactivity: Standard(GB6566-2000)

Main Characteristics of Calcium Silicate Board:

1. Light weight

2. The wall is solid and firm inside, and resistant to impact pressure

3. Painting, tiling and nailing is possible in the new system

4. Noise reduction can be up to 46 dB

5. Good efficiency

6. Fireproof, damp proof

7. Easy to install 8. Stable dimensions

Specifications of Calcium Silicate Board:

1) Thickness: 4 - 20mm

2) Normal Size: 1220*2440/1200*2400, with the maxium length 3.66m.

Usage of Calcium Silicate Board:

The magnesium board is widely adoptable to partition and suspending ceiling in decoration of buildings. It is also absolutely suitable to the structure for heat preservation, sound insulation wall places with dampness, mobile partition, special class fire prevevention, sandwiched plate in fireproof- gate and packaging of equipment cases.

Packaging & Delivery of Calcium Silicate Board:

Pieces with palletes or pieces loosely in the container.

- Q:Refers to the appearance

- Cement board is gray, that is, cementitious calcium silicate board is yellow and white

- Q:3.6 meters high, the ceiling has been equipped with fire pipes, air conditioning pipes, and now to do 2.8 meters of light steel keel calcium silicate board wall, how to fix the dragon keel, there is no regulation of governance Cui Huang Chao Chao The keel must be reinforced to the top? More

- Norms are not required to the top, depending on the actual situation, however, usually the wall of the dragon groves Cui Huangzhao Hao Tao Shu-ting do the top is a more formal approach if the firewall, fire requirements, keel must be the top, and the surface material But also to do the top; if the sound requirements are higher, but also need to do the top if the general wall, keel to the top will line. 2.8 meters above the location, the keel was based on the scene to bypass the electromechanical pipeline can be.

- Q:Is the calcium silicate board combustible? Some people say that it is completely non-combustible material, it was said that calcium silicate board only need one positive and one 8mm board to achieve one hour fire

- Calcium silicate board is non-combustible material, can do 1 hour fire aging.

- Q:Export of calcium silicate board or gypsum board, which one shipping cheap?

- Calcium silicate expensive, larger

- Q:8mm thick calcium silicate board (CalciumSilicateBoard) how much money a square meter!

- Taorong no asbestos fire calcium silicate board 2440MM * 1220MM, the factory tax price of 48 yuan each, the amount of Congyou

- Q:Living room to do silicon calcium board ceiling, whether need to put putty, brush latex paint?

- Direct brush on top of the ceiling will be on the latex paint, or easy to fall off

- Q:In the process of using the TK board or the use of silicon calcium board is the main choice is mainly to consider the bathroom waterproof and moisture-proof two kinds of materials which is more practical and economical Cost (cost)? General TK board how much money a plane, silicon calcium board about how much money a plane? More

- Toilet wall should be used (or processed to achieve) moisture-proof material, a good sound insulation performance; partition wall material requirements should be light, thin thickness, to adapt to the corresponding environmental requirements, drawn from local conditions. Wall can not afford to load-bearing role, only to separate the room and space of the wall, according to the different ways can be divided into block-type partition, vertical tendons, wall-type partition three categories. There are several kinds: light brick, glass tiles, glass, wood, gypsum board, new concrete slabs, ceramic plates, metal surface sandwich panels, etc., are also constantly developing innovation. Some of the non-waterproof material can be coated with a waterproof coating or past tile to enhance its water resistance. The reality is that the material is not expensive, expensive man. Plate prices from ten dollars to hundreds of dollars; and labor costs is basically two or three hundred. Therefore, according to local conditions to select the material process, improve production efficiency to save labor costs is the ultimate savings. If the project is large, through the factory production, on-site rapid installation can greatly reduce costs and improve competitiveness.

- Q:Calcium silicate brand Tingduo, but do not know which brand quality is relatively strong. More

- Matsumoto green new production of Matsumoto board of good quality, but also does not contain asbestos

- Q:Calcium silicate is afraid of high temperature

- Not afraid, high temperature materials

- Q:In the vicinity of the decoration shop to see several calcium silicate, what "east", "Baokang" are written green products, what ISO standards. But there is no asbestos, but I estimate the same price with the East (30 less than one, 6mm, 1.22X2.44), but there is no asbestos, There are also asbestos. Does this kind of calcium silicate board do ceiling ceilings? I want to find non-asbestos board, like "Taiwan-wing", that several shop owner said no. The board is too expensive to use. Why in line with national standards, but asbestos is harmful to the human body can be used? Do i use that kind of board now? More

- Asbestos is carcinogenic, building materials can not be used, the national standard is also can not be used. Iso is the quality management system certification, third party, not the country. Before the calcium silicate board because of the hardness requirements will be added, and now seems to have not added, but also not to say, small brand chaos plus what is not good to do the test. Must be used to find a well-known brand it, generally have detected, the key is to find the problem can find a good theory, the alternative to the same product gypsum board, mineral wool board, you can choose ah, you want the kind of , Gypsum board often used, cheap, mineral wool board sound-absorbing good, each have different bar. Landlord can refer to the next

1. Manufacturer Overview |

|

|---|---|

| Location | Foshan, China |

| Year Established | 1996 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; Australia; Africa; Southeast Asia;China |

| Company Certifications | ISO 9001:2008; CE EN12467:2012; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Foshan; Guangzhou; Shenzhen |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 5 people |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 100,000.00SQM |

| No. of Production Lines | 4 (plan add 2pcs product lines in 2014) |

| Contract Manufacturing | OEM Service Offered; Own Brand; |

| Product Price Range | 6mm Higt Density: USD2.72/SQM, Average price6mm Mid Density: USD1.85/SQM,Averange price |

Send your message to us

Calcium Silicate Boards Model 04 with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container pc

- Supply Capability:

- 35000Pcs/Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products