Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

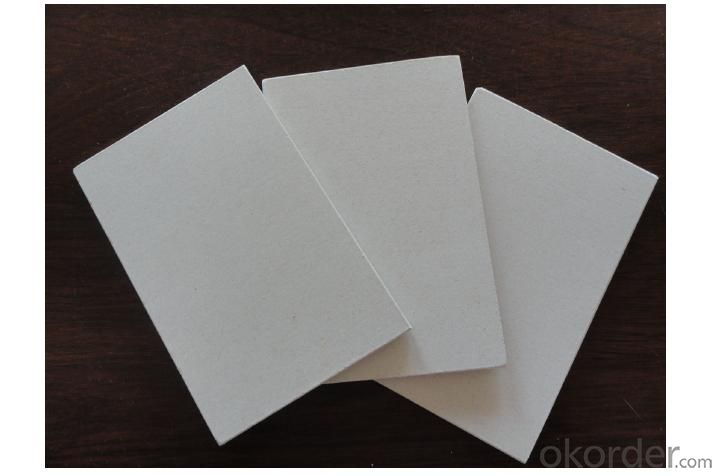

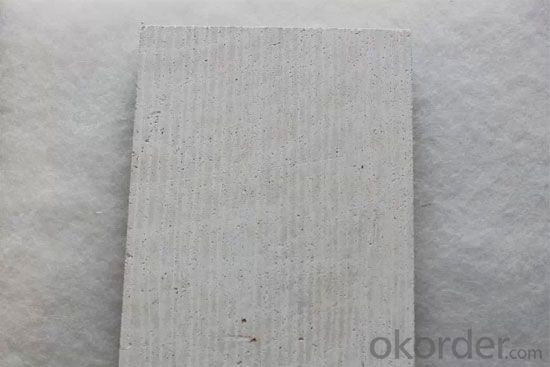

It can be applied not only in the interior use but also in the outdoor walls. It has low water absorption rate and high impact resistant ability. These advantages make it suitable for any purposes of applications.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

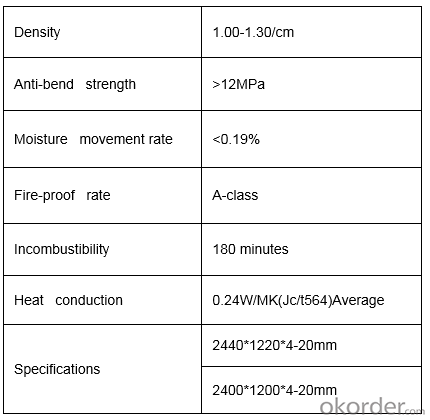

Main Product Features:

1) 100% non-asbestos

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W/MK (JC/T54)

4) Bending strength: over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: less 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

9) Incombustibility according to CNS 6532 and BS 476 standards

10) Two point five three hours of fire rating for 6mm wall system with W-CSP concrete

11) Radioactivity: GB6566-2000 standards

12) Characteristic: nonflammability A grade (GB-8624-1997)

13) Light weight

14) The wall is solid and firm inside, resistant to impact pressure

15) Painting, tiling and nailing is possible in the new system

16) Noise reduction can be up to 46dB

17) Good efficiency

18) Working environment can keep it dry and clean for better management .

19) Applications: can be used for partitions, interior walls, pipeline and conduit compartments, stair space, exterior walls, ceiling boards and pillar wrapping.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q:What is the amount of tropicin in the calcium silicate board? Or how to define? What is the effect of the content on the quality of calcium silicate board?

- The so-called calcium silicate board is through the siliceous material (quartz sand) and calcium material (slaked lime) at high temperature and pressure (autoclave) reaction to form terbutaline, and asbestos, pulp and other fibers are skeleton effect. As for the cement, it is the strength of its own use to increase the strength of calcium silicate board, and the use of its own with a small amount of calcium, thereby reducing production costs. But the cement in the calcium silicate board should not be used, otherwise one will bring the calcium silicate board color becomes darker; Second, the most important thing is to increase the deformation coefficient of calcium silicate board, which is the calcium silicate board is The most deadly.

- Q:Calcium and calcium silicate board and calcium carbonate plate distinction and contact

- Polymeric ceilings gypsum board, better. Because it is relatively soft, hardness is not very hard. It is relatively easy to shape. The operation is simple. But no calcium silicate board waterproof performance.

- Q:Calcium silicate board do background wall Why choose uv printer

- Election uv printer primary problem, should be from the printer machine stability, the choice of the nozzle, the latter part of the maintenance costs (replacement nozzle price), after-sales service and other factors to consider, it is recommended to choose Toshiba uv printer. Take the nozzle, the Ricoh g5 nozzle will be more than twenty thousand, while the Toshiba CE4 nozzle only 6000 or so, Toshiba life of 24-36 months, Toshiba nozzle printing speed is Epson twice as high precision than the high, Toshiba nozzle Warranty for two years, which determines the printer in the future use of the cost of the problem is increased.

- Q:External wall of calcium silicate board seams posted why the grid is also cracked

- Ordinary caulking agent is not enough, with the toughness of the sealing agent is more appropriate, with toughness anti-cracking, it is recommended to use the home of the heart of the card to worry about toughness sealant (TB).

- Q:Calcium silicate sound - absorbing panels with what inspection lot

- According to the use, the state has the best reverberation timetable for all kinds of halls, and the reverberation time of the audible field can be checked by the reverberation. With ordinary fire test whether the fire standards.

- Q:Bath area top need to paste mosaic, what material ceiling material to ensure that no deformation? Cement board Calcium silicate board

- Calcium silicate board is generally better than home, bathroom ceiling is generally aluminum plate and light steel keel

- Q:What is the difference between gypsum board and silicon calcium board?

- Gypsum board is a building gypsum (that is, CaSO4) as the main raw material, mixed with appropriate amount of additives (adjust the rate of condensation) and fiber to do plate core, with a special plate for the face, the processing of the plate. Strength is not high, not wet

- Q:Integrated ceiling and calcium silicate board which is good

- Calcium silicate board ceiling in addition to not in the kitchen outside the bathroom can be ... ... High strength, small thermal conductivity, high temperature, corrosion resistance Widely used in industrial and commercial construction of ceiling ceilings and partitions Because the fear of soot is not easy to clean up ... ... so different places to use a different ceiling

- Q:Calcium silicate board seams with what kind of waterproof tape can be affixed firmly. The

- To ensure that the seams on the edge of the screw effectively locked in the same keel. Second, leave the seam problem, you must ensure that more than 5 mm left seam.Three is the seam material problem, to ensure that the joints in the material into the powder and cellulose construction If the thickness of more than 6 mm, the best hanging plastic several times hanging, and so on the layer of glue dry and then hang a layer of glue, dry after hanging on the glue and other joints with dry after the best and then linked to white plastic The last seam belt, so that in the dry environment in the north will not crack,

- Q:What is the thermal conductivity of calcium silicate board?

- Calcium silicate board composition: low alkali cement + high purity quartz sand + perlite and other mineral fillers + plant fiber + amount of mica

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords