Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

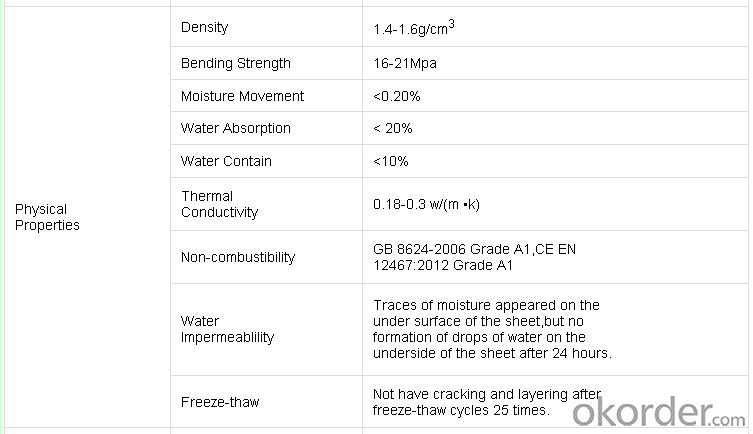

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q:Which is better adhesive or mourter for applying ceramic tile on cement board floor?

- The first and most common is Polymer Modified thinset. It's the least expensive, and the most common for a floor. MAKE SURE YOU GET POLYMER MODIFIED. It will say on the bag. The next is a premixed tile mastic. This is usually used for walls since it has more initial grab and helps keep the tiles from vertically sliding. There is nothing wrong with using premixed mastic as long as the tile is indoors. It will cost more however, and will also take longer to dry. If your doing a small area it might be easier since you don't have to mix it.

- Q:I would like to replace my carpet with a real hard wood floor., but my floor under the carpet is cement. Can any one give me advise as to how I go about this. want to do it myself.

- It can be a big job. You can use an engineered wood floor and glue it down (This is not like laminate more like plywood, the top layer is relatively thick and could be refinished years down the road if needed). First you have to make sure you don't have excessive moisture in the slab. Seal it if needed. I have a glue down hardwood floor my bedroom is 25+ years old and a few years ago did the rest of my house. It's fine. If you want to DIY do some reading about it first. Get a how to book on-line or at a home improvement center. It is certainly doable. The comment about access, regardless of your flooring choice ripping up the slab will obviously ruin the floor, so I don't think that is a consideration. Tile doesn't like being ripped up either.

- Q:This is a 1950s sink.

- I assume that you mean the tiles are attached to the counter-top. The process is called demolition, and it can get dusty. Safety glasses are a must, a dust mask is recommended. First, starting at the back-splash, slice any caulk at the seams where the tile joins the wall with a sharp knife. Then, crack the tiles, enough to get a pry-bar under them. Peel, pry or knock the tiles off, exposing the plywood or cement board underneath. If you can find screws or nails attaching the back-splash to the wall, remove them. Then, look underneath the counter for screw or nails which attach the cabinet to the wall, remove them. At this point, you can try prying the whole structure away from the wall(s). Be careful about pry-bar placement. You should only pry where there is a stud on the inside of the wall, typically every 16. If it doesn't budge, look for any fasteners you missed. NB- Before you start, turn off the water, disconnect all the plumbing, cover the drain pipe (to keep debris out of it and sewer gas inside it. A drop-cloth would help in the cleanup. expect to spend some time patching the wall when you're done. Good Luck

- Q:Fiber cement board and the difference between the water board

- Water board, also known as decorative concrete, is a water concrete slab. Different from ordinary concrete, it is smooth surface, uniform color, angular, no damage and pollution, but in the surface coated with a layer or two transparent protective agent, it is very natural, solemn.

- Q:Span 3 meters of the prefabricated plate can withstand much pressure

- This is generally dare not consider the students, first of all to determine the prefabricated board reinforcement, and then, and structural designers can support the next board support can withstand the maximum force is how much structural design instructions are generally explained, How much is the load, how much live is. The general plant now 350Kg / ㎡, residential office building, then 200Kg / ㎡, but also to the structural designer

- Q:What is the exterior wall of a light steel structure house?

- Fire, insulation, decoration in one of the professional insulation board Environmental protection without pollution, insulation, decoration, to avoid the cracks caused by the external wall of the external wall insulation caused by local shedding, and has a diversified color, convenient construction and many other advantages.

- Q:What are the standards for residential steel structures?

- China's steel structure housing industry has entered a new stage of development, the standard standards and architectural standards have been released to implement the design, coupled with adequate supply of domestic steel, but also a number of steel structure pilot project and demonstration project construction experience and scientific and technological achievements, The development of steel structure has a better material and technical basis. Of course, the promotion and improvement of different types of structural design specifications and construction technology standards, the development of new lightweight insulation wall materials and supporting the issue of residential parts, need to do a lot of work. At the same time, but also widely publicized the advantages of the development of steel housing, so that more developers, designers and users understand the understanding of steel housing.

- Q:My fear is that I will trap moisture where it shouldn't be. Is there such a thing as overkill?

- Tile council of America calls for a vapor barrier behind the cement board ..The red guard your talking about should and must be used on any horizontal surface in a wet area.. There are other agents like red guard but I v used it many times and had great luck w/ it..Making sure the proper pitch is used for the horizontal surface GL

- Q:Do I have to put cement backer board down before laying ceramic tile or can I go over existing vinyl floor?

- you can go over your old vinyl floor, just make sure its clean and flat and has no chance of infiltration. If you can't assure its steadfastness take it up

- Q:What kind of cirrcular saw blade do I use to cut cement board?

- a cement board blade works well

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords