Calcined Bauxite for Aluminate Cement Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcined Bauxite for Aluminate Cement Use

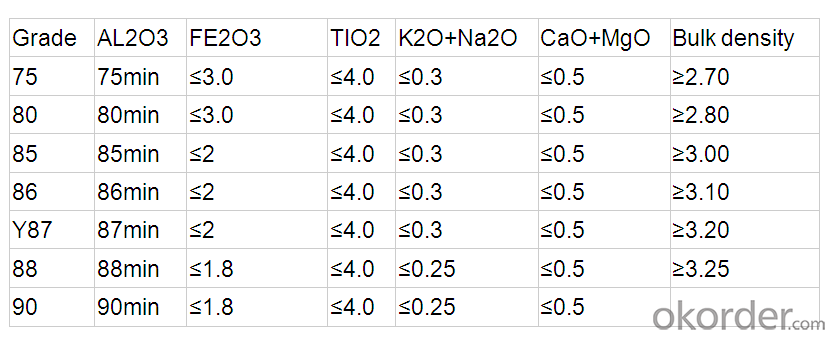

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Our Advantages;

1. We have substantial experience for material manufacture and export.

2. We establish a long-term relation of cooperation with raw material supplier, so we can offer you the best quality and price.

3. We have equipped 8 production lines and skilled workers to make the quality best.

4. We can control strictly quality at factory and third party testing institutions quality inspection.

5. We can also offer you the related test report, both at factory and the third party testing institutions.

6. We have sufficient manufacturing capability to deliver the goods safely and timely.

7. We can pack in 25kg bags, 1mt big bags, 1.25mt big bags or as your request. We can also pack with pallet.

8. We have professional service team keep customers informed from delivery to discharge.

Product Description:

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

Product Pictures:

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q:Does anyone knows which company produces the better refractory materials?

- I recommend Xinjiang Yuanyangrefractory material Co., Ltd. Address: Near Xishan Road No.100, Saybagh District,Urumqi. Their products are both in good quality and reasonable price. In addition, there are Xinjiang Zhongwang refractory material factory, Address: Xi hongxi Road No. 769, Urumchi City. They all have a good reputation. You may think about it. 。

- Q:Can anyone tell me what is a high alumina refractory?

- Refractories refer to a class of inorganic non-metallic materials whose refractoriness are no less than 1580 ℃. Refractoriness is the Celsius temperature when cone-shaped samples can resist high temperature without softening and melting down in the absence of a load. But it is not accurate to define refractory merely by judging that whether the refractoriness is no less than 1580 ℃. Currently, the materials whose physical and chemical properties allow them to be used in high temperature environments are called refractories. Refractory materials are widely used in metallurgy, chemical industry, petroleum, machinery manufacturing, power and so on, among which the metallurgical industry is the largest demander in this regard, accounting for 50% to 60% of total output. Hope it will help you out!

- Q:Does anyone know about the A-level fireproof materials?

- A-level decorative integrated plates of thermal insulation, water- and fire-proofing mainly can prevent fire and insulate heat with A-level fireproofing glass fiber as thermal insulation materials. The classification of A1-level external wall materials of thermal insulation, fire- and water-proofing: First, external wall thermal insulation materials: 1. silicate?thermal?insulation?materials 2. gelatine powder polyphenyl granules 3. steel wire gauze picking cement cystosepiment (grs board) 4. extruded sheets; Second, roofing materials: 1. xps extruded sheet 2. EPS foam board 3. perlite and perlite brick 4, vermiculite and vermiculite bricks; Third, heating and air conditioning materials: Polyurethane, rubberplastic sponge, polyethylene, polystyrene foam, glass wool, rock wool; Four, steel structure materials: Polystyrene, extruded sheet, Polyurethane board, glass wool roll mat, etc.

- Q:Which kind of external wall fire barrier zone material is better?

- I recommended foam cement and particulate thermal insulation composite waterproof material, which is fire isolation area product, which uses surface of vertical?plate arranged fiber technology to make the compressive?strength in the vertical direction up to above 80KPa. At the same time, under the conditions of both exterior heat insulation and effects of humiture in the long-term, it can still maintain the non-aging performance of various aspects, and safety (reliability), fire resistance and excellent durability.

- Q:what are the requirements of fireproofing material?

- The producing process of fire and moth proof wood: firstly, put general wooden materials into solution with calcium, aluminum and other cations, then soak it into the solution with phosphate radical, silicate and other anions. Thus, the two ions will be carried out chemical reaction in the wood, forming a ceramic-like material, and intimately fill the voids of cells, so that the wood has the fireproofing and mothproof properties.

- Q:How many fire endurance grades are the AAA fire resisting shutter divided?

- According to the fire endurance, the fire doors can be divided into Class A, Class B and Class C fire doors with the fire resistances are not less than 1.20h, 0.90h and 0.60h. Even the fire resistant level of B can also use the first rate fire resistant door.

- Q:How many grades of fire?rating are there for interior decoration materials?

- It can be divided into structural material and base?material based on materials. It can also be divided into flammable, flame retardant and non-combustible materials based on fireproof types. There is no fire?rating for materials. But lengths of time of flammability limits are different.

- Q:How is the grading of the level A new material fire insulation material?

- The thermal insulation materials are generally divided into level A and level B according to the flame rating. Level A is the non-combustible material, and level B is the combustible materials. The level B material is to blame for the fire in Shenyang hotel in CCTV building a few years ago . At present, the level A materials are widely used, with some prices even cheaper than the level B material. A level is roughly divided into insulation mortar, phenolic board, rock wool board and foam cement board, ect.

- Q:What thickness is needed of the ultra-thin fireproof paint with a fireproof time of 2.5 hours?

- Fireproof of steel components can adopt outsourcing concrete (or laying bricks method), fireproof coatings, fire prevention board coated and composite structure. Anti-firing plate can be divided into the fire protection lamella thickness plate and thin plate. Fire protection lamella thickness plate is of 20 ~ 50 mm. There are mainly calcium silicate and decayed stone of fire prevention board fire board, main varieties KB board, CF board; Fire sheet thickness is between 6 to 15 mm and the main varieties have short fiber reinforced cement pressure plate, fiber reinforced ordinary calcium silicate board and glass cloth reinforced inorganic plate. I hope you can be satisfied.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcined Bauxite for Aluminate Cement Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords