Calcined Anthracite Coal Recarburizer for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

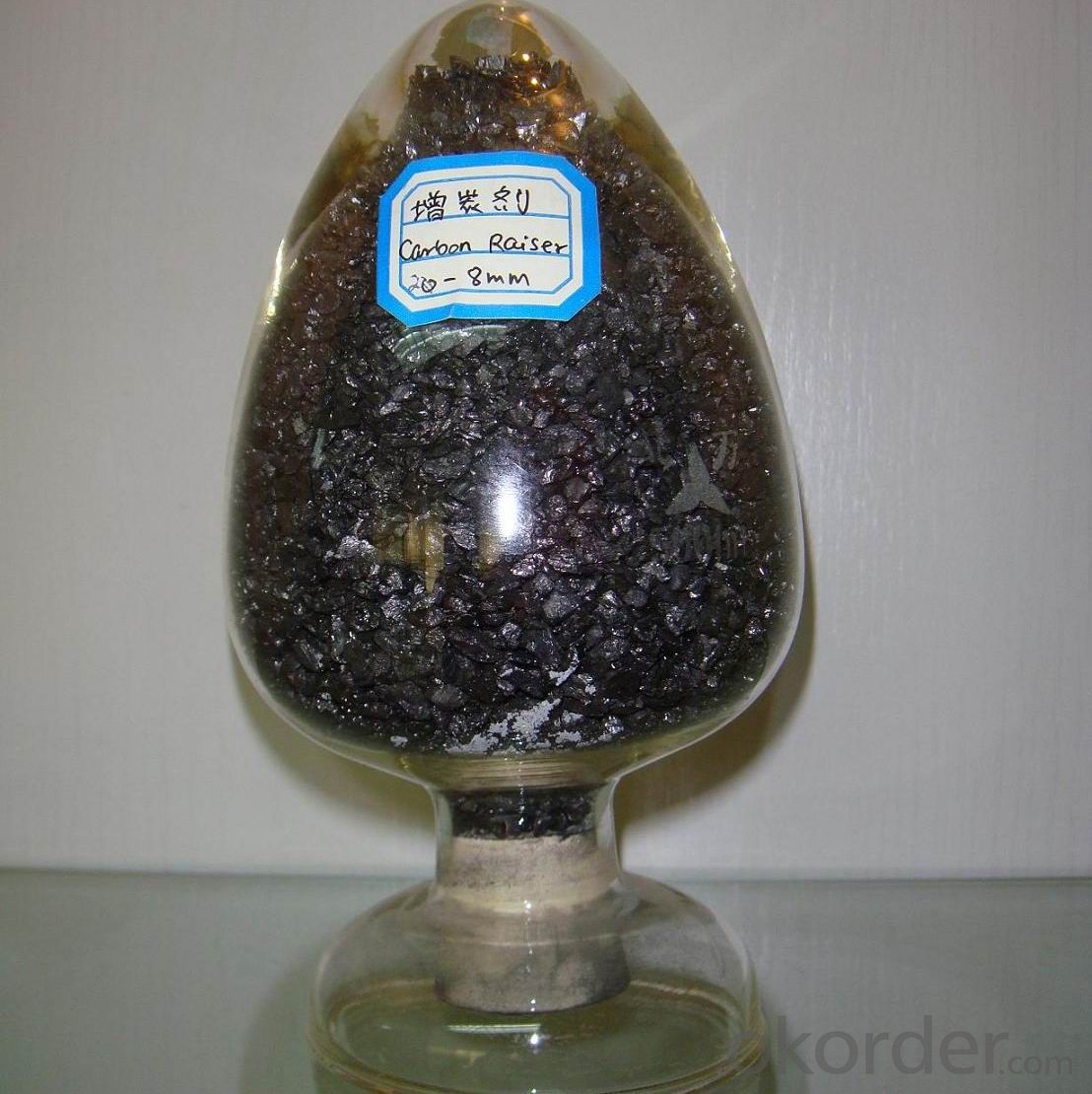

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Carbon Additve Low Sulphur for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additve Low Sulphur for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Carbon Additve Low Sulphur for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Carbon Additve Low Sulphur for Steelmaking

FAQ:

Carbon Additve Low Sulphur for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additve Low Sulphur for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q:A carbon Roast Lamb Leg stores need to how much money

- More than 40 thousand. If the scale is not large. If you want a prime location. And anything that's up to standard. Plus twenty thousand. If that's all. Buy something to ten thousand.

- Q:What is the role of carbon in respiration?

- Carbon plays a crucial role in respiration as it is a key component of organic molecules such as glucose. During respiration, glucose is broken down in the presence of oxygen to produce energy in the form of ATP. The carbon atoms in glucose are oxidized, releasing electrons that are ultimately transferred to oxygen, forming carbon dioxide (CO2) as a byproduct. This process, known as cellular respiration, occurs in all living organisms and is essential for the production of energy needed for various cellular processes. Without carbon, respiration would not be possible, and the energy required for growth, movement, and other life-sustaining activities would not be generated. Furthermore, the carbon dioxide produced during respiration is released into the atmosphere and serves as a crucial component of the carbon cycle, contributing to the regulation of Earth's climate and the growth of plants through photosynthesis.

- Q:What is carbon coffee fiber?

- The carbon coffee fiber uses the coffee residue left after the coffee and is made into crystal by calcining, then ground into nanometer powder and added to the polyester fiber to produce a functional polyester staple, a coffee carbon fiber.

- Q:What is carbon nanocomposite coating?

- Carbon nanocomposite coating is a type of protective coating that is made using carbon nanotubes or other carbon-based nanoparticles. These nanoparticles are dispersed within a matrix material, such as polymer or metal, to create a thin film that can be applied onto various surfaces. The main purpose of carbon nanocomposite coatings is to enhance the mechanical, thermal, and electrical properties of the coated material. The addition of carbon nanoparticles improves the strength, hardness, and wear resistance of the coating, making it more durable and long-lasting. It also provides excellent corrosion resistance, making it suitable for applications in harsh environments. One of the key advantages of carbon nanocomposite coatings is their ability to provide multifunctional properties. For example, they can be engineered to have high electrical conductivity, which makes them ideal for applications in electronics and electrochemical devices. Additionally, they can have high thermal conductivity, making them useful for heat dissipation in electronic devices or as a thermal barrier coating. Moreover, carbon nanocomposite coatings have shown promising results in various fields such as aerospace, automotive, energy, and healthcare. In aerospace, they can be used to improve the performance and durability of aircraft components, while in the automotive industry, they can provide anti-scratch and self-cleaning properties. In energy applications, they can be utilized to enhance the efficiency of solar panels or to prevent corrosion in oil and gas pipelines. Additionally, in healthcare, they can be used for drug delivery, as antibacterial coatings, or for bio-sensing applications. Overall, carbon nanocomposite coatings offer a wide range of benefits, including improved mechanical and electrical properties, corrosion resistance, and multifunctionality. With ongoing research and development, these coatings hold great promise for various industries, providing innovative solutions to address their specific needs and challenges.

- Q:Why can carbon fiber in addition to static electricity ah?

- Is graphite conductive? Think about it!

- Q:Joint carbide gas incident

- The Central Bureau of investigation in India after the disaster had 12 official allegations, including the Union Carbide (India) Co., Ltd. India 8 executives when he was chairman of Warren Anderson and company, two small companies and the company itself and under the. The 1 indicted India executives have been killed, the court 7 days to negligence causing death sentence the remaining 7 India nationals guilty, including the then Indian president Keshub Mahindra is more than 70 years old, many people. According to the charges, they will be sentenced to two years in prison at most. Survivors of the gas leak and their families and local activists gathered in front of the court 7 days ago, holding banners protesting the punishment of the perpetrators too light and late. Since the conviction was made in a local court in India, the defendant had the right to appeal to a higher court, and it was estimated that the process would continue for several years. After the disaster, Anderson, the American boss of the company, returned home soon. Now he lives in New York. In July last year, the court issued an arrest warrant for Anderson, but it has not been mentioned below.

- Q:What are the different types of carbon-based inks?

- A variety of carbon-based inks are commonly utilized in different applications. One category is carbon black ink, produced by burning organic substances like wood or petroleum products in a low-oxygen environment. This ink is renowned for its deep black hue and is frequently employed in printing and calligraphy. Another kind is carbon nanotube ink, created by dispersing carbon nanotubes in a liquid medium. Carbon nanotubes are minuscule cylindrical structures composed of carbon atoms, and their distinctive electronic properties make them valuable in applications such as flexible electronics and energy storage devices. There is also graphene ink, made by dispersing graphene flakes in a liquid medium. Graphene consists of a single layer of carbon atoms arranged in a hexagonal pattern, and it possesses remarkable strength, electrical conductivity, and flexibility. Graphene ink is utilized in various applications, including flexible electronics, sensors, and batteries. Furthermore, conductive carbon-based inks are employed in electronics and circuitry. These inks usually contain a combination of carbon particles and a binding material, and they are used to create conductive pathways on substrates like paper or plastic. Overall, carbon-based inks offer a vast array of possibilities due to the unique properties of carbon materials. They find applications in diverse fields, including printing, calligraphy, electronics, energy storage, and more.

- Q:How does carbon impact food production?

- There are several ways in which carbon affects food production. To begin with, carbon dioxide (CO2) is a significant greenhouse gas that plays a role in climate change. The presence of higher levels of CO2 in the atmosphere leads to increased temperatures, changes in rainfall patterns, and more frequent extreme weather events. All of these factors can have a negative impact on crop growth and productivity. For instance, excessive heat can result in lower crop yields and reduced quality, while intense rainfall or droughts can cause flooding or water scarcity, both of which can harm crops and decrease agricultural productivity. Moreover, carbon emissions originating from agricultural practices, such as the utilization of synthetic fertilizers, deforestation for agriculture, and livestock production, contribute to the overall carbon footprint of the food system. These emissions worsen climate change, establishing a vicious cycle in which climate change has an adverse effect on food production, while food production, in turn, contributes to climate change. Furthermore, the production of food is also influenced by carbon emissions from its transportation and processing. The transportation of food over long distances, which often involves the use of fossil fuels, leads to carbon emissions. Similarly, the processing and packaging of food require energy, often derived from fossil fuels, which further adds to carbon emissions. To alleviate the carbon impact on food production, it is necessary to adopt sustainable agricultural practices. This includes techniques like agroforestry, organic farming, and precision agriculture, which can help store carbon in soils, reduce dependency on synthetic fertilizers, and enhance overall soil health. Additionally, reducing food waste and promoting the consumption of local and seasonal food can decrease carbon emissions associated with transportation and processing. In conclusion, carbon affects food production through its contribution to climate change and the resulting extreme weather events, as well as through emissions generated from agricultural practices and food processing. Addressing these impacts is crucial for ensuring food security and sustainability in the face of climate change.

- Q:What is the density of carbon?

- Carbon's density varies depending on its form. Graphite, the most prevalent form of carbon, has a density of 2.267 g/cm³. In contrast, diamond, another form of carbon, boasts a significantly higher density of 3.515 g/cm³. Therefore, it is crucial to specify the form of carbon being discussed when referring to its density.

- Q:How does carbon affect the formation of cyclones?

- Carbon does not directly affect the formation of cyclones. Cyclones, also known as hurricanes or typhoons, are formed through a complex interaction of various atmospheric and oceanic factors. Carbon, specifically carbon dioxide (CO2), is a greenhouse gas that contributes to global warming and climate change. It is important to note that while carbon dioxide concentrations in the atmosphere are increasing due to human activities, such as burning fossil fuels, it does not directly cause the formation of cyclones. However, climate change resulting from increased carbon dioxide levels does have an indirect influence on cyclone formation. Warmer temperatures due to climate change can lead to increased sea surface temperatures, which provide the energy necessary for cyclone formation and intensification. Higher temperatures also increase evaporation rates, leading to more moisture in the atmosphere that can fuel cyclone development. Furthermore, climate change can alter atmospheric conditions and circulation patterns, which may affect the frequency, intensity, and tracks of cyclones. However, the specific impact of carbon dioxide on cyclone formation and behavior is still an active area of research, and more studies are needed to fully understand the relationship between carbon dioxide and cyclones.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcined Anthracite Coal Recarburizer for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords