C-glass Fiberglass Mesh Marble Net for Buildings and Wall

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

C-glass Fiberglass Mesh Marble Net for Buildings

Definition of C-glass Fiberglass Fabric Mesh

E-glass Fiberglass Mesh Marble Net is mainly alkali-resistant fiberglass fabric. Fiberglass Mesh mainly use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. Fiberglass Mesh is an ideal engineering material in construction and decoration industry.

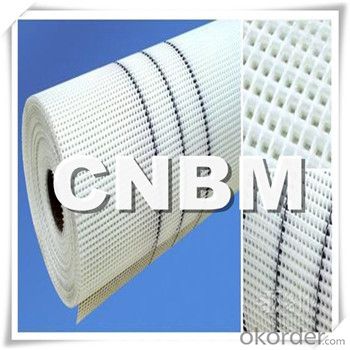

Image of E-glass Fiberglass Mesh Marble Net

Application/Usage of C-glass Fiberglass Mesh Marble Net

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement Fiberglass Mesh, Electrical heating mats Fiberglass Mesh

Marble slab reinforcement / Mosaic carrier Fiberglass Mesh, Asphalt reinforcement (roof water-proof) Reinforced lightweight construction boards Fiberglass Mesh.

C-glass Fiberglass Mesh Marble Net Production Process

Application :

Package: E-glass Fiberglass Fabric Mesh are packed in shrink-wrapped, then put into cartons or pallets.

Packing volumes: about 20000m/20FCP, 40000m2/40HQ.

Delivery: About 15 days after confirming the order.

FAD:

Q: What is the storage of Fiberglass Mesh?

Store Fiberglass Mesh out of direct sunlight, away from direct contact ground or concrete;

Store Fiberglass Mesh rolls in cool, dry location, away from weather or other damage.

Q: What is the guarantee period of Fiberglass Mesh ?

Fiberglass Mesh: Four years under normal weather conditions and usage directions.

Q: What is the Advantage of Fiberglass Mesh ?

Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

Good dimensional stability & positioning property, stiffness, smoothness an difficult to shrink & deformation.

Good impact resistance and not easy to be teared.

Q: Why choose our CNBM Fiberglass Mesh?

We are the manufacturer of Fiberglass Mesh, price will be reasonable and much competitive

We have produced Fiberglass Mesh strictly in according to customers' detailed requirements

CNBM Fiberglass Mesh theme is: Good Quality, High Credibility & Best Service.

- Q:cracking resistant mortar and the adhesive force of the mesh

- Cracking mortar is an organic adhesion agent, the product has a high bonding strength, inorganic binding material mixed by a certain percentage, and it is usually made of a thermal insulation with galvanized steel or alkali fiberglass mesh cloth composite coating, not powder cracking, wall panels, graded sand, the product has high strength, and is cement concrete products.

- Q:What is the difference between geotextiles and fiberglass fabrics?

- The company production of needle punched geotextile mainly to high quality polyester staple fiber, can also according to the production of polypropylene, nylon, vinylon or mixed fiber needle punched geotextile user requirements. Needle punched geotextile with isolation, filtration, drainage, reinforcement and protection, closed the six major functions, mainly used for roadbed, the road (highway, railway, airport) and ground stability; strengthening highway and railway soft ground reinforcement; surface protection and dams, blocking wall drainage material; beach and swamp reclamation and reinforcement materials.

- Q:Balcony gauze nets, in the end to buy glass fiber yarn net or 304 stainless steel yarn net?. What are the advantages?

- Must not be cheap to buy glass fiber yarn network. That glass blowing after exposed to the weather, home, everywhere, all these. Never use it.

- Q:Which is better to stick the cloth, the mesh or dacron cloth

- Mesh is widely used in current renovation to prevent cracking of the wall.

- Q:What kind of fiberglass mesh is needed to touch the outer wall?

- The glass fiber mesh cloth plastering generally for inner wall inner wall and then is the exterior wall hanging wire to heat so that the external walls are used for building on the two is a kind of indispensable not only

- Q:The difference between glass fiber and carbon fiber

- Carbon fiber is a fibrous carbon material, containing more than 90% carbon. It is made by carbonization of various organic fibers in inert gas and in high temperature. Carbon fiber has excellent mechanical properties, is the highest strength and the highest modulus fiber with high performance fiber has been mass production, especially high temperature and inert environment in above 2000 C, carbon material is the only strength of the material, the other is the main structural material (metal and alloy) incomparable. In addition to excellent mechanical properties, but also has many other excellent properties of carbon fiber, such as low density, high temperature resistance, corrosion resistance, friction resistance, anti fatigue, vibration attenuation, high power and high thermal conductivity, low coefficient of thermal expansion, X light penetration is high, but the non magnet electromagnetic shielding.

- Q:The costs of posting mesh are reasonable?

- It is mentioned to stick mesh in the construction technology which is included in the unit price. But in the process of construction, the foreman insisted on separate charge for the cost of the mesh, this is reasonable? T The process content in the Contract is as follows : 1: cleaning brush metope beauty solid nest wall again, 2: the nest bottom paint plaster leveling, 3: brush the nest wall fixed grid cloth, 4: the nest easily shave - 400, 2-3 times, 200 - watt bulb light and grinding smooth, brush primers, 5: Excluding special wall treatment, such as required gray sand leveling, the cost of another 15 yuan per square meter. 6: This offer provides paint, roller, brush wool and other disposable utensils from Party A. 7: To paint additive color is no more than two colors, one color for each additional should plus $ 150.

- Q:Which is the best screen for polyester fiber screen window and fiberglass screen window?

- Polyester fiber advantages: strong, dry and wet, good color fastness, shrinkage stability, fabric has certain drape, as well as the general color gorgeous. Disadvantages: moisture absorption, poor ventilation

- Q:What CE certification should glass fiber gridding cloth be done?

- CE certification is a kind of safety certification and regarded as a pass of manufacturer to Europe market.

- Q:Does anyone know the specification of alkali-resistant fiberglass mesh?

- To further improve the secure and stable durability of alkali-resistant fiberglass mesh, after being processed into gauze shape, and again coat it with butylbenzene and pure?acrylic, and adopt a constant speed constant tension control technology to make it adhesive ( this process is put forward by BASF from Germany, who developed alkali resistant coating technology for alkali-free glass fiber grid cloth ) .In early times it can effectively resist polymer mortar Ca (OH)2 hydration's erosion to glass fiber mesh cloth. After coating, slip resistance strength of mesh junction reaches 3.5 ~ 4.5N.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

C-glass Fiberglass Mesh Marble Net for Buildings and Wall

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords