C Channel Steel (Height: 50–400mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 42000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

C Channel Steel (Height: 50–400mm)

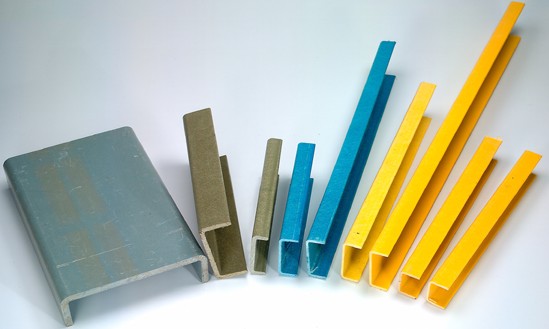

OKorder is offering high quality C Channel Steel (Height: 50–400mm) at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

C Channel Steel (Height: 50–400mm) is ideal for use in the construction of ships, vessels and other steel structures.

Product Advantages:

OKorder's Channel Steel is durable, strong, and resists corrosion. Additionally, our steel is easily assembled with the assistance of trained engineers.

Main Product Features:

· Short construction period

· Strong

· Experienced engineer assistance

· ISO9001 & SGS certification

· Easy to assemble and dismantle

· Can be recycled and reused

Product Specifications:

Ordinary Model

Height: | 50 – 400mm |

Thickness: | 4.5 – 14.5mm |

Surface: | Painted, Galvanized, As per customer request |

Length: | As per customer request |

Size: | 50 X 37 X 4.5mm—400 X 104 X 14.5mm |

Punch: | Can be punched as per customer request |

Material: | Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540 ASTM A36 |

Light Model

Height: | 50 – 400mm |

Thickness: | 4.4 – 8.0mm |

Surface: | Painted, Galvanized, As per customer request |

Length: | As per customer request |

Size: | 50 X 32 X 4.4mm – 400 X 115 X 8.0mm . |

Punch: | Can be punched as per customer request |

Material: | Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540 ASTM A36 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:How are steel channels protected against rust and corrosion?

- Steel channels are protected against rust and corrosion through various methods such as galvanization, coating with protective paints or sealants, and applying corrosion-resistant treatments to the surface.

- Q:Are steel channels resistant to pests and termites?

- Steel channels offer a high level of resistance against pests and termites. In contrast to wooden channels, which can easily be infested and damaged by termites and other pests, steel channels create a formidable barrier that pests cannot breach. Steel, being an inorganic material, lacks the necessary elements for pests to thrive or find sustenance. Be it rats, termites, or any other pests, they are incapable of gnawing through steel, thus eliminating the risk of damage to steel channels. Moreover, steel channels remain unaffected by rot or decay, further enhancing their resistance to pest infestation. Consequently, if you seek a durable and pest-resistant option, steel channels present an excellent choice.

- Q:What are the different insulation options for steel channels?

- Some different insulation options for steel channels include foam insulation, fiberglass insulation, and mineral wool insulation. These materials can help to reduce heat transfer and improve energy efficiency in buildings or structures that use steel channels.

- Q:Channel 10, 1 meters. What is the theoretical weight?

- Channel 10, 1 meters, theoretical weight is 10.007kg.

- Q:What are the different methods for designing steel channels for high wind loads?

- There exists a variety of approaches for creating steel channels that can withstand strong winds. Some commonly utilized methods include: 1. Load and Resistance Factor Design (LRFD): By employing load and resistance factors, LRFD determines the necessary strength of steel channels. Wind speeds and building dimensions are used to calculate the loads, while resistance factors are based on material properties and safety considerations. 2. Allowable Stress Design (ASD): This method converts wind loads into equivalent static loads and compares them to the allowable stresses of steel channels. Factors such as material properties, safety considerations, and load combinations are taken into account when determining the allowable stresses. 3. Wind Tunnel Testing: Engineers construct a scaled-down model of the building and subject it to simulated wind conditions during wind tunnel testing. This enables the analysis of airflow patterns and measurement of forces acting on the steel channels. The data obtained from wind tunnel testing can then be used to refine the design and optimize the dimensions of the steel channels. 4. Finite Element Analysis (FEA): FEA is a numerical method that allows engineers to simulate the behavior of steel channels under various wind loads. By dividing the structure into small elements and applying appropriate boundary conditions, FEA accurately calculates stresses, deformations, and displacements in the steel channels. This enables engineers to optimize the design and identify areas of high stress concentration that may require reinforcement. 5. Prescriptive Design Codes: Numerous countries have specific design codes and standards that provide guidelines for designing steel channels to withstand high wind loads. These codes outline minimum requirements for channel dimensions, material properties, connections, and fasteners. By adhering to these codes, the steel channels can be designed to withstand expected wind loads. It should be noted that the choice of design method may vary based on factors such as the complexity of the structure, available resources, and project-specific requirements. Consulting with a structural engineer experienced in designing for high wind loads is recommended to ensure a safe and efficient design.

- Q:What are the different weight classifications for steel channels?

- Steel channels are categorized based on their weight per linear foot, which includes lightweight, medium weight, and heavy weight classifications. Lightweight steel channels typically weigh between 1.0 to 6.0 pounds per linear foot. These channels are commonly utilized in applications where strength is not the primary consideration and where the load requirements are relatively lower, such as in decorative or non-structural uses. Medium weight steel channels have a weight per linear foot ranging from 6.1 to 16.0 pounds. These channels are frequently employed in structural applications where there is a need for moderate strength and load-bearing capacity, such as in building frames, supports, and bracing. Heavy weight steel channels weigh between 16.1 to 40.0 pounds per linear foot. These channels are specifically designed to provide maximum strength and load-bearing capacity, making them ideal for heavy-duty structural applications like industrial buildings, bridges, and infrastructure projects. It should be noted that the weight classifications for steel channels can vary depending on the specific standards and specifications established by different countries and organizations.

- Q:Are steel channels suitable for use in the construction of scaffolding systems?

- Yes, steel channels are suitable for use in the construction of scaffolding systems. Steel channels are strong, durable, and provide the necessary support and stability required for scaffolding structures. Additionally, steel channels can be easily assembled and disassembled, making them a practical choice for scaffolding systems that need to be frequently moved or adjusted.

- Q:Can steel channels be used for curtain wall systems?

- Yes, steel channels can be used for curtain wall systems. Curtain wall systems are typically composed of lightweight materials, such as aluminum or steel, that are designed to create an exterior wall system that is non-structural and serves as a protective barrier against weather conditions. Steel channels can be used as the framing system for curtain walls, providing structural support and allowing for the attachment of glass panels or other cladding materials. Steel channels offer several advantages for curtain wall systems, including their high strength-to-weight ratio, durability, and ability to be prefabricated off-site for efficient installation. However, it is important to consider the specific design requirements and load calculations when using steel channels for curtain wall systems to ensure they meet the necessary structural and performance criteria.

- Q:How are steel channels classified based on their shape?

- Steel channels are classified based on their shape into three main categories: C channels, U channels, and miscellaneous channels. C channels, also known as C-shaped channels or simply channels, have a distinct shape resembling the letter "C". They have a flat vertical back and two horizontal flanges extending outward from the back. C channels are widely used in construction and structural applications, providing excellent load-bearing support. U channels, also referred to as U-shaped channels or simply U-channels, have a U-shaped cross-section with two vertical sides and a horizontal base. The two vertical sides are known as flanges, while the horizontal base is called the web. U channels are commonly employed in manufacturing and fabrication processes, offering stability and strength to various structures. Miscellaneous channels encompass all other steel channel shapes that do not fit into the C or U channel categories. These channels can have a range of shapes and sizes, including tapered flanges, uneven sides, or unique profiles. Miscellaneous channels are utilized in specialized applications where specific design requirements need to be met. In summary, steel channels are classified based on their shape into C channels, U channels, and miscellaneous channels, each serving different purposes in construction, manufacturing, and other industries.

- Q:Can steel channels be used for modular construction systems?

- Yes, steel channels can be used for modular construction systems. Steel channels are versatile and have high strength, making them suitable for various applications in modular construction, such as framing, support structures, and connections. They provide stability and durability to modular buildings and can be easily assembled and disassembled, allowing for flexibility and ease of modification.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

C Channel Steel (Height: 50–400mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 42000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords