BZ Model Column Cantilever Crane,Lifting Equipment,Crane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

Cantilever crane structure is unique, safety and reliable, with high efficiency, energy saving, time saving, flexible features. Especially suitable for lifting in short, intensive places. It is widely used in workshops, warehouses, docks and other fixed places. The working level is A3 in normal.

BZ Model Column Cantilever Crane is composed of column device, slewing device, swing arm device and chain electric hoist. The lower end of the column is fixed on the foundation of the concrete; rotary arm rotation, according to user demand for rotation. The rotary part is divided into manual rotary and electric rotary. The chain electric hoist is mounted on the slewing arm track for lifting heavy objects.

Feature

Column cantilever crane is one kind of crane which replies on seat fixed. According to the product structure is divided into:

- Lower seat fixed column cantilever crane with rotary hinged shaft

The rotation angle ≤270°, the cantilever of the crane is fixed on the column and rotated by the rotary hinge shaft, the lifting capacity and the effective gyration radius are smaller. Lifting weight is within 1 tons, the maximum effective gyration radius is within 5 meters.

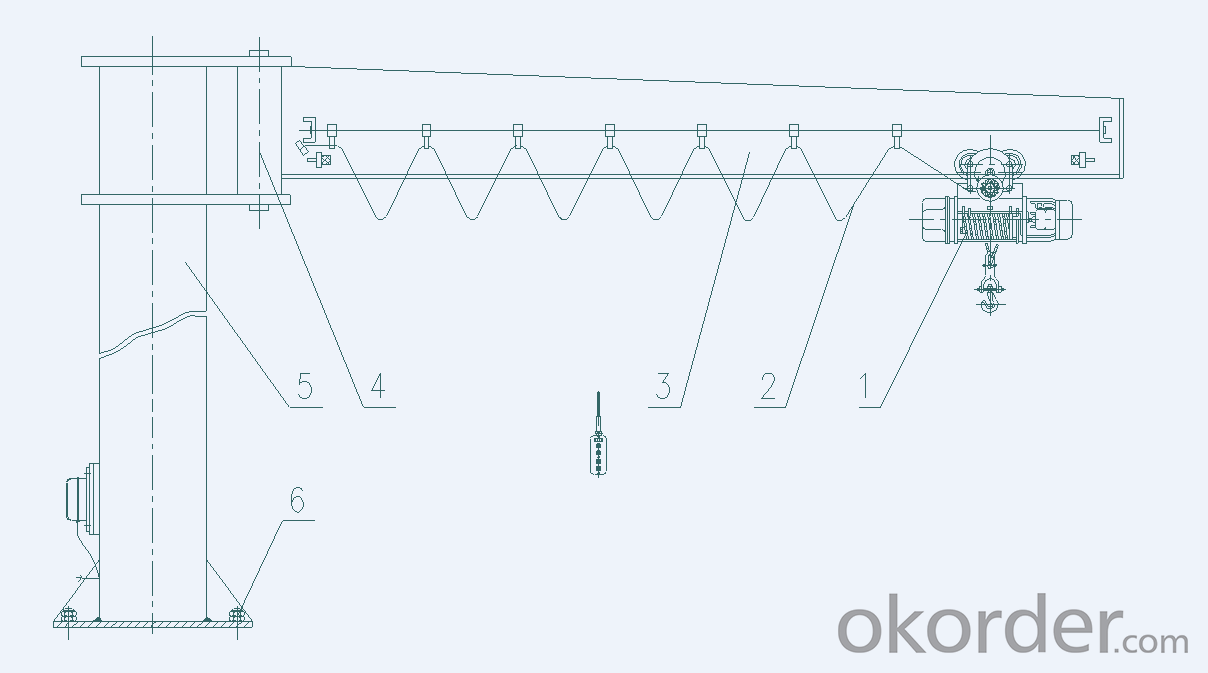

1.Electric hoist 2.Electric device 3.Main beam 4.Slewing gear 5.Column 6.Lower fixed seat

Figure 1 - Lower seat fixed column cantilever crane with rotary hinged shaft

- Lower seat fixed column cantilever crane with supporting arm

The rotation angle ≤360°, the cantilever beam has a supporting arm, makes the stress form of the main beam and column is much more better; and it also makes the general minimum turning radius is bigger. Lifting capacity is generally less than 5 tons, and the maximum effective gyration radius is within 6 meters.

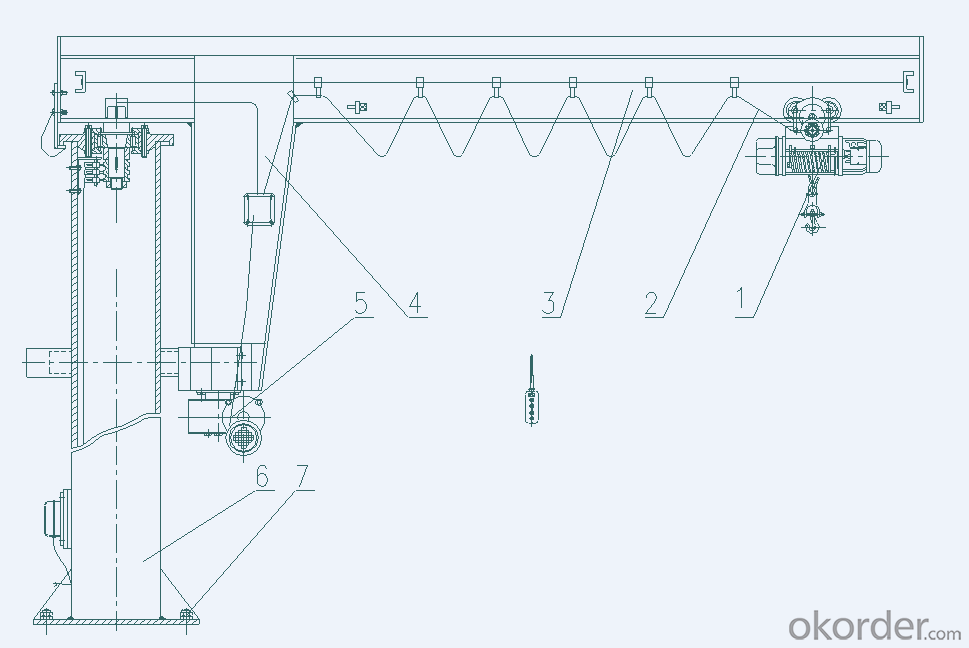

1.Electric hoist 2.Electric device 3.Main beam 4.Supporting arm 5.Column 6.Rotary hinge shaft 7.Lower fixed seat

Figure 2 - Lower seat fixed column cantilever crane with supporting arm

- Lower seat fixed column cantilever crane with slewing bearing

The rotation angle ≤360°, this type of cantilever crane adopts slewing bearing structure; the main beam and the column are connected by slewing bearings, it makes the minimum gyration radius smaller, the lifting capacity and effective cantilever of structure are increased greatly. Lifting capacity can reach 10 tons, and the maximum effective gyration radius can reach 10 meters.

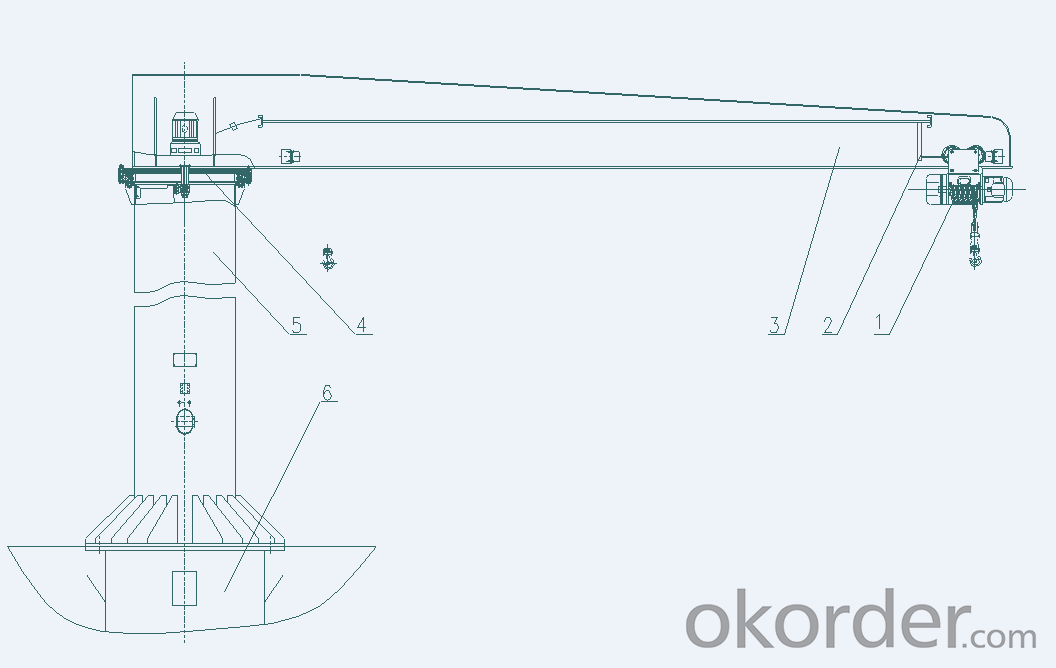

1.Electric hoist 2.Electric device 3.Main beam 4.Skewing gear 5.Column.6.Fixed base

Figure 3 - Lower seat fixed column cantilever crane with slewing bearing

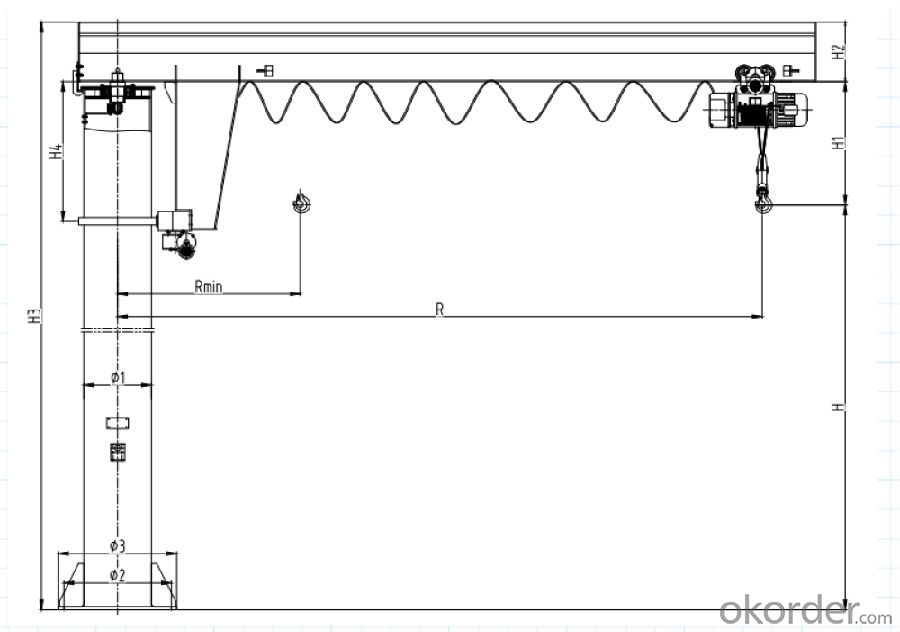

Technical Specification

Lifting Capacity | t | 1 | 2 | ||||||

Lifting Height (H) | m | 3 | 4 | 5 | 3 | 4 | 5 | ||

Effective Radius of Gyration (R) | m | 3 | 4 | 5 | 3 | 4 | 5 | ||

Working System | A3 | ||||||||

Speed | Hoisting | Normal | m/min | 8 | |||||

Slow | m/min | 0.8 | |||||||

Slewing Speed | r/min | 0.5~1 | |||||||

Trolley Travelling Speed | m/min | 20 | |||||||

Rotation Angle | ° | 180 270 360 | |||||||

Max. Height (H0) | mm | 4130 | 5207 | 6234 | 4430 | 5514 | 6514 | ||

Max. Length (L) | mm | 3210 | 4210 | 5210 | 3200 | 4200 | 5200 | ||

Total Weight | Kg | 1100 | 1375 | 1714 | 1467 | 1803 | 2392 | ||

Technical Specification

Lifting Capacity | t | 3 | 5 | ||||||

Lifting Height (H) | m | 4 | 5 | 6 | 4 | 5 | 6 | ||

Effective Radius of Gyration (R) | m | 4 | 5 | 6 | 4 | 5 | 6 | ||

Working System | A3 | ||||||||

Speed | Hoisting | Normal | m/min | 8 | |||||

Slow | m/min | 0.8 | |||||||

Slewing Speed | r/min | 0.5~1 | |||||||

Trolley Travelling Speed | m/min | 20 | |||||||

Rotation Angle | ° | 180 270 360 | |||||||

Max. Height (H0) | mm | 5550 | 6634 | 7646 | 5970 | 7120 | 8120 | ||

Max. Length (L) | mm | 4200 | 5200 | 6200 | 4250 | 5250 | 6250 | ||

Total Weight | Kg | 2060 | 2990 | 3480 | 3100 | 3870 | 4250 | ||

- The maximum effective cantilever and lifting height what below 2T and 2T are 5m. The maximum effective cantilever and lifting height of 3T and 5T are 6M. When the non-standard tonnage and non-standard effective cantilever and lifting height are required, special explanation is needed. The standard work level is A3, and special explanation should be given when needs more than A3 work level.

Condition of Environment

1.Power source: three phase A/C.Rated frequency: 50HZ. Rated voltage: 380V.

2.Height of site: no more than 2000m.

3.Flammable, explosive and corrosive gas are forbidden around the working environment.

4.The crane is forbidden to lift molten metal, toxic products and flammable and combustible gas.

Installation

Before installation, according to the packing list the product and technical documents should be checked for shortage or loss; The bending and torsion deformation of the swing arm beam, rust and bruise of the shaft in the transit should be corrected or restore; in addition, every half a year, the shaft, bearing and other rotating parts should be cleaned and lubricated.

- Column installation

The column should be kept vertical with the ground, and the baseboard screw should be tightened firmly, and no loosening phenomenon. The floor and base should be well fitted. If equipped with electric hoist, the foundation should be buried cable and grounding facilities, the pre buried cable is drawn from the base center, the grounding resistance shall not exceed 4 ohms.

- Swing arm beam installation

(1) Lift the beam horizontally

(2) Connect the slewing gear with the jib beam. Install reducer.

(3) Install electric hoist and walking trolley on the track of cross arm beam (The installation method is strictly according to the ‘use and maintenance instructions’ of the chain electric hoist).

(4) Install C track at the top of the beam. The C type track has self made sliding trolley, and it should be on the same side with the electric control box of the chain hoist.

(5) Connect all the appliances on the beam by wire, and keep the power line with proper length. The C type track jigger and cable are fixed separately with tie wires.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BZ Model Column Cantilever Crane,Lifting Equipment,Crane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords