Butterfly Valves Ductile Iron Wafer Type DN500

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 80000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

1. Small in size and light in weight, easy instillation and maintenance. It can be mounted wherever needed

2. Simple and compact construction, quick 90 degrees on-off operation

3. Minimized operating torque, energy saving

4. Flow curve teeing to straight line, excellent regulation performance

5. Long service life, standing the test of tens of thousands opening/closing operations

6. Bubbles-tight sealing with no leakage under the pressure test

7. Wide selection of materials, applicable to various mediums

8.Simple and compact construction. Small in size and light in weight. Easy transportation, installation and maintenance.

9. Quick 90 degrees on-off operation. Minimized operating torque ,energy saving.

10. Excellent sealing performance with no leakage. Long service life.

11. Wide selection of materials ,applicable for various media..

12. Flow curve tending to straight line. Excellent regulation performance.

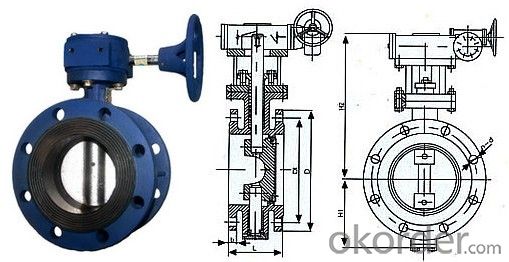

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:What's the difference between turbine butterfly valve and manual butterfly valve?

- Butterfly (Manual butterfly) butterfly plate installed in the direction of the diameter of the pipe. In the butterfly valve body cylindrical channel, the disc shaped disc rotates around the axis. The angle of rotation is between 0 and -90 degrees. When rotating to 90 degrees, the valve is fully open.Butterfly valve structure is simple, small size, light weight, only by a few parts. The utility model can be rapidly opened and closed only by rotating 90 DEG, the operation is simple, and the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the butterfly plate thickness is the only resistance when the medium passes through the valve body, so the pressure drop produced by the valve is very small, so the flow control characteristic is better. Butterfly valve has an elastic seal and metal seal, two types of seals. Resilient sealing valve. The sealing ring can be mounted on the valve body or attached to the periphery of the disc.

- Q:What are the major disadvantages of butterfly valves?

- Also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the flow of air, water, steam steam, all kinds of corrosive medium, mud, oil, metals and radioactive liquid media and other types of fluid. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.shortcoming1, use pressure and working temperature range is small.2, poor sealing.Butterfly valve can be divided into bias plate, vertical plate, inclined plate and lever by structure. According to the form of sealing, can be soft sealed and hard sealed type of two. The soft sealing type usually adopts rubber ring seal, and the hard sealing type usually adopts metal ring seal.According to the connection type can be divided into flange connection and clamp type connection; according to the transmission mode can be divided into manual, gear drive, pneumatic, hydraulic and electric several.

- Q:Check valve; flexible joint `; installation order of electric butterfly valve

- It is better to make an elastic hanger.In order to prevent the generation of water hammer when the pump stops the damage to the rubber head, should be immediately set rubber head pump outlet, the gate valve and the check valve is not a very convincing reason to decide the order, custom order rubber head, check valve, electric butterfly valve.

- Q:Butterfly valves are widely used in 2.0MPa below the pressure and temperature of not more than 200 degrees of various media, right?

- 3. kinds of butterfly valve:According to the connection mode: flange type, clip type.According to the material of sealing surface, soft seal and hard sealing.According to the structural form, butterfly valves can be divided into the following types:Plate typeInclined plate typeOffset plateLever type4. butterfly valve features:(1) the structure is simple and the shape is small. The utility model has the advantages of compact structure, short structural length, small size and light weight, and is suitable for large caliber valves.(2) the resistance of the fluid is small, and when the valve is fully opened, the valve seat passage has an effective circulation area, so the fluid resistance is smaller.(3) open and close, convenient and quick, good adjustment performance, butterfly plate rotation 90 degrees can be completed headstock. By changing the angle of rotation of the disc, the flow can be graded.(4) the opening and closing moment is smaller, because the butterfly plate on both sides of the rotating shaft is basically equal to the medium, and the opposite direction of the torque is generated, so that the opening and closing is more labor-saving.(5) low pressure sealing performance, sealing surface materials generally use rubber, plastic, sealing performance is good. Limited by the material of the sealing ring, the pressure and the temperature range of the butterfly valve are smaller. But the use of hard sealing butterfly valve pressure and temperature range has been greatly improved.

- Q:What's the use of fire butterfly valve?

- You should ask the signal butterfly valve, butterfly valve in the fire signal system which is a monitoring alarm signal, its purpose is to ensure that the valve has been opened in the daily state, to prevent misuse operation was closed, thus affecting when accidental fire extinguishing. Therefore, it is necessary to set up the signal valve!

- Q:Butterfly valve D71X-10 and butterfly D371X-10 what is the difference?

- One more 3 in D71X-10 stands for adding a worm gear to the valve. What are the same, the difference is driven by the handle into the drive, gear drive, worm gear drive for large caliber butterfly valve a little less, because the valve torque is big, big, hard to handle and can rotate, and if the worm, you can turn a few laps handwheel. If there are other questions, we can continue to ask questions, the city butterfly valve manufacturers

- Q:How to use the fire butterfly valve properly?

- Clamp and groove type and signal butterfly valve, the first two have what requirements of installation, the operating handle can rotate to open and close the valve installation, signal wiring, mouth down, to prevent water and caused a short circuit three line grounding and alarm line for leakage protection and monitoring of the valve open or closed, general are in line with the alarm valve or flow indicator matched with water, indicating the spacing of not less than 300mm, no other special requirements

- Q:Are fire fighting signal valves and signal butterfly valves the same thing?

- The same nature: both can open and close, there is also information back fed.Signal valves are collectively referred to as signal butterfly valves.

- Q:What's the difference between D71X-16 and D71H-16 butterfly valves?

- First, model D71X model means that, on behalf of 7 representative D butterfly valve, butterfly valve connection form for clamp connections, 1 straight, X represents the seal in the form of soft sealing, the sealing surface usually NBR H metal seal is usually 2Cr13 16 represents the pressure of 16 kg pressure weldingJin Ya valve is the production of hard sealing butterfly valve or soft sealing butterfly valve line leader, what problems can ask their units, technicians will answer for you

- Q:D341W-10P-400 butterfly valve, what does each alphanumeric letter mean?

- According to JB/T308-2004 "valve type programming method"D butterfly valve3 worm gear4 flange connection1 Structure: sealed type, central vertical plateW sealing material for valve body material10 nominal pressure PN10P body material is chromium nickel stainless steel400 shall be nominal size DN400

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valves Ductile Iron Wafer Type DN500

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 80000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords