Butterfly Valve Steel Threaded Directional with Plastic Handle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

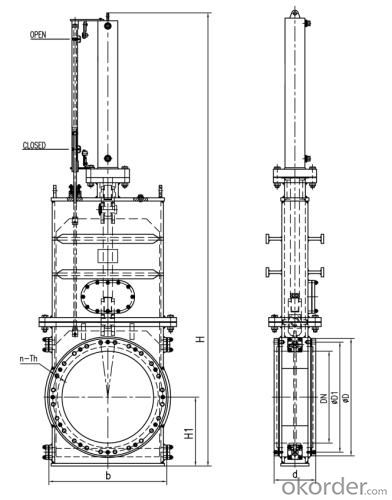

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:What's the advantage of using three way valves?

- The principle of three way valve:The most obvious three valves and other valves is the difference in appearance, three way valve has three channels, mainly used to change the medium to flow through valve three, which in addition to import A, B, C and reversing port of export, common valve is not capable of changing the flow direction of medium function. The flow direction of the medium can be determined according to requirements.

- Q:Where is the Shanghai valve? What brand is good?

- A lot of Shanghai brand brand of Shanghai KaiWeiXi, Department of finance the Kemei high Lidun Shanghai Karon these are good

- Q:Valve category can fill the trunk door, branch valve Mody?

- Each of these types of valves have very different varieties, such as the valve can be divided into: self sealing valve, knife gate valve, gate valve, cryogenic insulation jacket valve, seal valve, vacuum valve, flexible valve seat seal, valve, gate valve, signal buried forged steel gate, cast iron gate valve and so on.

- Q:What does the PN on the valve mean?

- 1, mark "ON25" and "PN16" respectively what does that mean? 2, the valve above has an outer six corners, so PN16 refers to the nominal pressure of 16 kg valve. Valves on the fittings are standard parts, special

- Q:Remove the handle and lever the stem rotation with a wrench,

- First you know what valve you need, or you know where to use the pipe material, so you do not need to understand the valve material.

- Q:How do you calculate the valve wall thickness, pressure, and other valve design calculations in a spreadsheet?

- Which standard does the wall thickness refer to? ASME B16.34?Design and calculation depends on what standard you chooseOr have you found the standard yourself and read it yourself?You choose what standards, design parameters reference, interpolation or fitting, how to fit, are their own sayI wrote a excel series of valve calculations, it does not take long to writeFor long-term useIn order to improve efficiencyOr write your own database program is better

- Q:What does the whole copper valve mean?

- The whole valve is made of copper material. In addition to the ceramic core.

- Q:How to quickly identify the types of valves?

- The "Practical Handbook" valve design on the valve structure, with precision, surface roughness and typical design standard, the valve has hundreds of models, and continue to have a new valve, see a written one, is shorthand.Valves: valves (Valve) control the flow of fluid medium flow, flow, pressure, temperature and other mechanical devices, valves are the basic components of the pipe system. Valve fittings are technically similar to pumps and are often discussed as a separate category. Valves can be operated by hand or hand wheel, handle or pedal, or by control to change the pressure, temperature and flow change of fluid medium. The valve can perform continuous or repeated operations on these changes, such as a safety valve installed in a hot water or steam boiler. In more complex control systems, automatic control valves are required depending on external inputs (i.e., regulating the flow through the pipe to the changing setting points). Automatic control valve without manual operation, according to its input and settings, so that the valve accurately control the requirements of fluid medium. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves, chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q:How can the material be checked by valve approach? What experiments do you need?

- First of all, to check material certification, and secondly, the material appearance, shape and size of the initial test, again on the alloy material according to the standard spectrum analysis, the valve to do pressure test.

- Q:What is the valve before and after the pump?

- General pump should be installed before and after the pressure regulating valve, pump installed before the pressure drop valve, pump installed after the pressure regulator valve!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve Steel Threaded Directional with Plastic Handle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products