Butterfly Valve Stainless Steel Threaded Directional with Plastic Handle Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

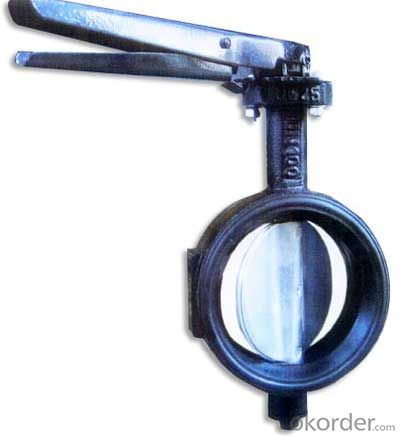

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:How does the valve rust die?

- Go to the hardware store to buy derusting lubricant, W40 is fine.

- Q:Tell me the exact address, or the phone number in the market. Where is the industrial zone (the valve) in Hefei? Please help, thank you

- Hardware city inside, on the opposite side of the East Second Ring Guoqiang steel market

- Q:the use of natural connections, is strictly prohibited counterparts. What do you mean by "strong opposition"?

- Refers to the installation of the interface dislocation, misalignment or installation of the wrong size and forced connection, resulting in installation stress exists, in use, it is prone to abnormal damage.

- Q:The total valve of my natural gas was closed by the attitude I tried. Now I can't open it. I need to use gas. Who knows how to drive it? What skills do I have? I'm talking about the main valve.

- Are you talking about using air? Or your valve is a pneumatic emergency shut-off valve

- Q:What does the 4 point valve mean?

- Commonly used valves, pipes in the 4 points, 6 points, an inch, is the earliest use of the length of the British unit, metric units are 15, 20, 25 mm, and now people are also used to call 4 points, 6 points, an inch.1 inches =25.4 mm1 feet =12 inches1 inches =8 cents

- Q:Is there any problem with connecting the geothermal valves with other geothermal pipes?

- Can be universal,Material is the same, the fuse will not cause shrinkage when you can use

- Q:Where is the valve used?

- Generally in the pipeline above, such as the government to improve people's livelihood, engineering, factories and so on the pipeline above, Wenzhou essence valve factory

- Q:What valve is the YQZ45X-16Q?

- Specifically, YQ usually is the enterprise code, Z valve, 4 representative flange, 5 representatives of the dark bar, X (soft) rubber seal (gate coated with rubber material), nominal pressure 16 representative (PN) 1.6Mpa, Q on behalf of the valve body is made of ductile cast iron. If you add the valve bore (DN), it will be more detailed.

- Q:Remove the handle and lever the stem rotation with a wrench,

- Monel alloy is mainly applied to the valve in the medium containing hydrofluoric acid.6, Hastelloy alloy is mainly used in the valve of strong corrosive medium such as dilute sulphuric acid7, titanium alloy is mainly applicable to all kinds of strong corrosive medium valveRecommendations for the GB standard of steel and ASME second A copies at American Standard. For American Standard steel can also see ASME B16.34

- Q:High and low pressure valve is how to distinguish?

- Vacuum valve - valve with operating pressure below standard atmospheric pressure.Low pressure valve - nominal pressure PN is less than 1.6MPa valve.Medium pressure valve - nominal pressure PN 2.5~6.4MPa valve.High pressure valve - nominal pressure PN10.0~80.0MPa valve.Ultra high pressure valve - nominal pressure PN greater than 100MPa valve.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve Stainless Steel Threaded Directional with Plastic Handle Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords