BUTTERFLY VALVE DUCTILE IRON ISO/ API/ DIN/ BS DN800/ DN900/ DN1000/ DN1100/ DN1200

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard or Nonstandard: | Standard | Structure: | Butterfly | Pressure: | Medium Pressure |

| Power: | Manual | Material: | Ductile Iron | Temperature of Media: | Medium Temperature |

| Media: | Water | Port Size: | DN40-1200 | Place of Origin: | China (Mainland) |

| Model Number: | 220 | Brand Name: | CNBM |

Packaging & Delivery

| Packaging Detail: | PLYWOOD OR WOODEN BOX |

| Delivery Detail: | 15--30 DAYS |

Specifications

Wafer Butterfly Valve

1.MSS/API/BS design.

2.Size: DN40-1200.

3.Working pressure: PN10/16/25.

4.ISO9001/ABS/CCS/DNV/CE

Quick Details

Standard or Nonstandard: | Standard | Structure: | Wafer | Pressure: | Medium |

Power: | Manual | Material: | Cast iron, Ductile iron, WCB, SS316,C954 | Temperature of Media: | Normal |

Media: | Water, Oil, Gas | Port Size: | DN40-DN1200 | Place of Origin: | China |

Brand Name: | CNBM | Certification: | ISO9000, CE,CCS,DNV,ABS,TS | ||

Packaging & Delivery

Packaging Detail: | Each Piece into one bubble plastic bag, several pcs into one Wooden crate or according to customers requirements |

Delivery Detail: | within 30 days |

Specifications

Size: 2”-24” / 40mm – 1200 mm

Design standard: API 609, BS EN 593, MSS SP-67.

Face-to-Face dimension: API 609, ISO 5752, BS EN 558, BS 5155, MS SP-67.

Flange Drilling: ANSI B 16.1, BS EN 1092, DIN 2501 PN 10/16, BS 10 Table E, JIS B2212/2213 5K, 10K, 16K.

Test: API 598.

Lever / worm gearbox operator / electric operator / pneumatic operator

Our product features are as follows:

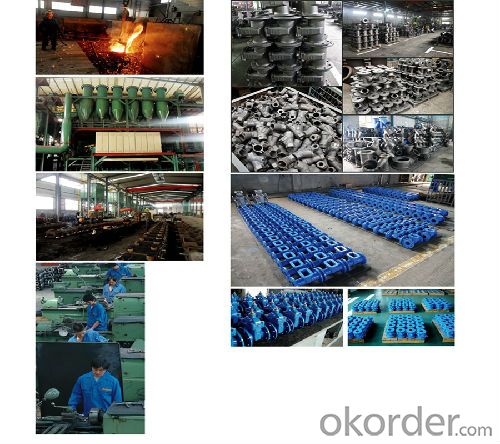

1. Newly developed facilities ensure high and stable quality.

2. Enable to supply UL/FM valves.

3. Experienced technology

4. Excellent after-sale service to satisfy customers.

5. Sufficient capacity ensures prompt delivery.

6. Continuous quality improvement and new designs development.

7. Reasonable and stable price

8. Meets different countries standards, such as ANSI,DIN,BS etc.

Working pressure:

10Bar/16Bar/25Bar

Flange accommodation:

ANSI B16.1 Class125/150

AWWA C207

MSS SP44 Class150

DIN 2501 PN6/10/16

EN1092-2 PN6/10/16

BS10 Table D/E

JIS B2220 5K/10K/16K

AS4087 PN14/16

Top Flange:

ISO5211

Tightness check:

API 598

ISO 5208,

EN12226-2

Pressure Temperature Ratings | |

working pressure | 16bar/25bar |

testing pressure | shell:24bar/37.5bar |

seal:17.6bar/27.5bar | |

working temperature | -20 degree to 110 degree EPDM seat |

-10 degree to 80degree NBR seat | |

suitable media | Water, Oil& Gas. |

- Q:I have put a new pressure valve and replaced both thermostat

- so that should have fixed it I wonder if you needed to replace the stats

- Q:Butterfly valve model D344H and D343 difference

- [1] D344H-10C DN400, D343H-10C DN400, to talk about the 2 types of butterfly valves in common: D on behalf of 3 Representatives is butterfly valve, turbine driven, 4 representative is in the middle of flange, representing 10 kg pressure, C is the representative of the valve material is cast steel, DN400 represents the valve diameter; say that there the difference of the 2 models, there is a place where there are differences, second means 4 of the first models is the new type sealing valve structure is variable eccentric, second of the second models of the 3 represents the structure of the valve is three eccentric, and three eccentric seal type variable eccentric in fact, is a meaning.Sealed three eccentric butterfly valve, sealed variable eccentric butterfly valve, corresponding to the central butterfly valve and sealed single eccentric butterfly valve.

- Q:The difference between butterfly valve d71x_10s and d341s-10

- Before distinguishing between the two, you must first read the identification of the valve type:D stands for butterfly valves,3 means that the worm gear is connected and the drive does not indicate the handle7 and 4 indicate pipe to clamp connection, pipe flange connection, respectively1 means single eccentric, that is, the stem is not in the center of the butterfly plateThe former S indicates the material name of the valve body - plastic, X means sealing and the lining material is rubberThe latter S indicates the sealing lining material code ---- plastic, and the valve body is cast iron.10 means stress.

- Q:Hi guys, i asked a question before pertaining to the amount of cylinders and asking if it meant V4 or V6 or whatever.I actually meant to say VALVES, not cylinders. IS there a direct correlation between VALVES and Clyinders..Eg, My car, which is a 2001 Neon LE states right on the engine block quot;16 VALVEquot; in bright letters. I am sure this is a 4 cylinder engine. I haven't had a car that broadcasted the number of VALVES before. Another car I had broadcast that is was a 3.3 Liter V6 right on the engine.Is there a mathematical relationship between VALVES and cylinders, or would my car be braodcasting 16 VALVES, because a 4 cylinder doesn't typically HAVE 16 valves, or what is the story??Recently, I was looking at an altima, and it said 24 valves. Can you tell just by the number of valves if it is a 4 cylinder or 6 cylinder or whatever??Thanks.

- Well a lot of valves signify that more air/gas is getting to the engine so it suggests a more powerful engine. So your car has 4 valves per cylinder. Now that's pretty much a standard number so most expensive cars don't really even talk about that. They mostly just advertise the displacement. You can't really tell the type of engine via the number of valves because it does vary by manufacturer. For example there could be a 16 valve V8 also also(2 valves per cylinder). There are some ratios that dont work like a 16 valve V6 because you cannot have 2.6 valves.

- Q:oil coming from valve into turbo charger

- depends on the year of the duramax, some do have a pvc valve one is on the valve cover on one year and on another year the valve is down at the bottom of the engine it screws in, i would check with your local dealer, the should give you an idea, if the turbo has an line follow it the other is just mainly a vent on the valve cover, is the oil coming in or coming out of the turbo?

- Q:Who can give me a download UG butterfly valve, needle valve, diaphragm valve standard model address, Japanese standard, American Standard.

- Give you the address bar, this is a three-dimensional CAD model library of an online version of the real registered mail, free of charge, there are hundreds of Chinese and foreign manufacturers of the product model is available for download, such as ABB, SMC, FESTO, AIRTAC, CAMOZZI, MISUMI etc..

- Q:Butterfly valves are widely used in 2.0MPa below the pressure and temperature of not more than 200 degrees of various media, right?

- First of all, is not the butterfly valve butterfly valve.Butterfly valve in the valve around the fixed axis rotating valve, called butterfly valve.1., as a sealed butterfly valve, it has been developed rapidly since the appearance of synthetic rubber, so it is a new type of shut-off valve. In our country until 1980s, the main role of butterfly valves in low-pressure valves, valve seat using synthetic rubber, by 90s, hard seal "metal seal" butterfly valve to rapid development. There are a number of valve factory can produce steady pressure metal seal butterfly valve, butterfly valve shall be shipped to a broader area.2. butterfly valves can transport and control the medium with water, condensed water, recycled water, sewage, sea water, air, gas, liquid gas, dry powder, mud, fruit pulp and a mixture of suspended solids.The domestic butterfly valve parameters are as follows:Nominal pressure: PN0.25 - 4.0MPaNominal diameter: DN100 - 3000mmWorking temperature: less than or equal to 425 DEG C

- Q:What is an electric two position butterfly valve?

- It's an electric valveProduct brief:??Electric double position butterfly valve, this product is connected with flange type, clip type. Material: cast iron, carbon steel, stainless steel, 304/316Product overview???Electric double position butterfly valve (soft seal) is suitable for temperature less than 200 DEG C, adjust the flux and closure of the role of the medium nominal pressure is less than 1.6MPa of food, medicine, chemical, petroleum, electric power, textile, papermaking, water supply and drainage, gas pipeline. ?main features1 reasonable and novel design, unique structure, light weight, rapid opening and closing.2 operating torque is small, easy to operate, saving smart.3 can be installed in any position, convenient maintenance.4 seals can be replaced, reliable sealing performance to achieve two-way seal zero leakage.5 sealing material aging resistance, corrosion resistance, long service life etc..Electric double position butterfly valve adopts standardDesign standard: GB/T12238-1889Flange size: GB/T9113.1-2000; GB/T9115.1-2000; JB78Length: GB/T12221-1889Pressure test: GB/T13927-1992; JB/T9092-1999

- Q:Model specification for butterfly valves

- Various classifications of butterfly valves1. classification by structure:(1) Central sealed butterfly valve(2) single eccentric sealed coal valve;(3) double eccentric sealed butterfly valve(4) three eccentric sealed stamp valve;

- Q:Not the cold and hot water shut off valves. The one with a tiny handle and it looks like a T. what does it do? should I mess with it?

- Is the valve coming off a water supply line? if so, it's a needle valve probably installed at some point during a remodel or while adding an appliance. If it's on the cold side it will most likely go to a refrigerator ice maker or water dispenser, if it's on the hot side it may go to a dishwasher or other device that requires hot water.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BUTTERFLY VALVE DUCTILE IRON ISO/ API/ DIN/ BS DN800/ DN900/ DN1000/ DN1100/ DN1200

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products