Butterfly Valve Ductile Iron Cast Iron Can be Customised High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

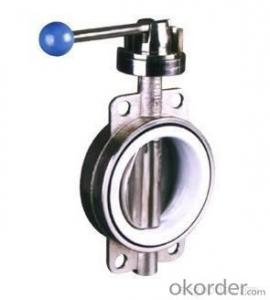

1. Manual Wafer Butterfly Valve Description:

The products are widely used in industries such as water projects, urban water supply & drainage, sewage treatment, eletric power, petroleum, petrochemical, heat supply, shipbuild-ing,medicine and metallurgy. Equipment used in regulating or cutting off medium in pipeline

2.Main Features of the Manual Wafer Butterfly Valve

Quick DetailsStandard or Nonstandard: Standard Structure: Gate Pressure: Medium Pressure

Power: Manual Material: Casting Temperature of Media: Medium Temperature

Media: Water Port Size: DN40mm-DN300 Place of Origin: China (Mainland)

Model Number: CMAX-GF4 resilient gate valves: resilient seat flange

Packaging & DeliveryPackaging Detail: air plastic bag inside/wooden box outside

Delivery Detail: 15-60days

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

2. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:What's the difference between turbine butterfly valve and manual butterfly valve?

- Butterfly (Manual butterfly) butterfly plate installed in the direction of the diameter of the pipe. In the butterfly valve body cylindrical channel, the disc shaped disc rotates around the axis. The angle of rotation is between 0 and -90 degrees. When rotating to 90 degrees, the valve is fully open.Butterfly valve structure is simple, small size, light weight, only by a few parts. The utility model can be rapidly opened and closed only by rotating 90 DEG, the operation is simple, and the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the butterfly plate thickness is the only resistance when the medium passes through the valve body, so the pressure drop produced by the valve is very small, so the flow control characteristic is better. Butterfly valve has an elastic seal and metal seal, two types of seals. Resilient sealing valve. The sealing ring can be mounted on the valve body or attached to the periphery of the disc.

- Q:What are the butterfly valves models?

- Divided by connection:1 pairs of clip butterfly valveThe butterfly plate of the clip butterfly valve is installed in the direction of the diameter of the pipe. The valve is fully open.The clip butterfly valve is simple in structure, small in size and light in weight. Butterfly valve has an elastic seal and metal seal two types of seals. Resilient sealing valve. The sealing ring can be mounted on the valve body or attached to the periphery of the disc.2, flange butterfly valveThe flange butterfly valve is a vertical plate structure, and the stem is a sealing ring of an integral metal hard sealing valveFor flexible graphite plate and stainless steel plate composite structure, mounted on the valve body, butterfly plate sealing surface of stainless steel surfacing. The sealing ring of the soft sealing valve is made of nitrile rubber and is mounted on the butterfly plate.3, lug butterfly valve4 、 welded butterfly valveWelding type butterfly valve is a non sealed butterfly valve, widely used in medium temperature less than building materials, metallurgy and mining, electric power production process at 300 nominal pressure 0.1Mpa pipe, used to open and close connected, or adjust the medium quality.

- Q:does it come in when you go over a certain rpm or do the valves change depending on how far you depress the throtle?

- The variable is the valve timing. The spark plug fires a split second before the piston reaches the top of the stroke, to give the fuel a bit of time to burn. But, the faster the piston travels in the bore, that split second gets shorter shorter. So the engine computer changes when the spark plug fires when the valves close, to maximize the power from each ignition stroke.

- Q:Check valve; flexible joint `; installation order of electric butterfly valve

- Connect the Songjiang rubber joint from the pump outlet. Check the 1 valve

- Q:What kind of butterfly valve is sd342x?

- Sd342x: two-way double eccentric soft sealing butterfly valveS: two way pressureD: butterfly valve3: turbine operation4: flange connection2: double eccentricX: rubber sealProbably the shape is not so good in appearance,Double eccentric mostly elastic sealThree eccentric is multi-layer sealHope to be of help to youOpened valve Co., Ltd. on the production of butterfly valve

- Q:What's the difference between a butterfly valve and an eccentric butterfly valve? What is the difference in field applications?

- Eccentric butterfly valve and ordinary butterfly valve, when the butterfly valve is opened, the eccentric butterfly valve sealing surface will reduce great wear, in the opening, the disc will leave the valve at the first time the sealing surface!

- Q:What is an electric two position butterfly valve?

- It's an electric valveProduct brief:??Electric double position butterfly valve, this product is connected with flange type, clip type. Material: cast iron, carbon steel, stainless steel, 304/316Product overview???Electric double position butterfly valve (soft seal) is suitable for temperature less than 200 DEG C, adjust the flux and closure of the role of the medium nominal pressure is less than 1.6MPa of food, medicine, chemical, petroleum, electric power, textile, papermaking, water supply and drainage, gas pipeline. ?main features1 reasonable and novel design, unique structure, light weight, rapid opening and closing.2 operating torque is small, easy to operate, saving smart.3 can be installed in any position, convenient maintenance.4 seals can be replaced, reliable sealing performance to achieve two-way seal zero leakage.5 sealing material aging resistance, corrosion resistance, long service life etc..Electric double position butterfly valve adopts standardDesign standard: GB/T12238-1889Flange size: GB/T9113.1-2000; GB/T9115.1-2000; JB78Length: GB/T12221-1889Pressure test: GB/T13927-1992; JB/T9092-1999

- Q:Seat has said to the previous owner that the car needs a new air mass meter and dump valve.I am putting a new air mass meter on it.Does it have a dump valve.I know very little on this subject.

- every turbo will have a dump valve(waste gate) to regulate the boost to the engine Dump valves are fitted to the engines of turbo charged cars and sit between the turbo outlet and the throttle body. When transitioning from a boosted state to a closed throttle state (as in between shifts), due to inertia, the turbo continues to pressurize air, but the closed throttle prevents the compressed air from entering the engine. In this case the pressure exceeds the preset spring pressure in the dump valve and the excess pressure is bled off to atmosphere. Even with a dump valve the compressed air acts as a brake on the turbo (slowing it down), because the pressure on the backside of the turbo is at a higher pressure than on the front side (and the air actually wants to flow through the turbo backwards). A blowoff valve is a more elegant solution to this problem by allowing the turbo to freewheel when the throttle is closed (equalizing the pressure on both sides of the turbo). Unlike a dump valve a blowoff valve can be used at multiple boost settings without reconfiguration. Blowoff valves are sometimes incorrectly called dump valves because they serve a similar function, but they are very different solutions to the same problem.

- Q:Butterfly valve network and ordinary butterfly what is the difference?

- 1. The butterfly valve of the pipe network adopts an eccentric structure. When closed, it has the function of closing and tightening. The sealing performance is reliable. After opening and closing, the cover is completely sealed, and the cover is completely out of contact, so as to ensure that the sealing surface is not damaged.2, the sealing surface is made of stainless steel, corrosion resistant, high temperature resistant, long service life. With two-way sealing function, medium flow is not affected by the installation restrictions (if only one-way control medium should be used to seal the installation direction) is not affected by a single space, can be installed in the any direction.

- Q:Not the cold and hot water shut off valves. The one with a tiny handle and it looks like a T. what does it do? should I mess with it?

- Hi There I installed a valve with a t-type handle for my refrigerator's ice maker. This is a saddle type valve which is place on a water line and taps into the water inlet . It has a piece of rubber around the needle valve so it will not leak. If there is no plastic or copper line protruding from the line then it should lead to an ice maker. Now I have seen the same type of valve which was placed on the water line and then hooked up to the dishwater. Either way don't mess with it unless it leaks... Why the pipe it is attached too will have to be replaced. Been there done that check out the two links below

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve Ductile Iron Cast Iron Can be Customised High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords