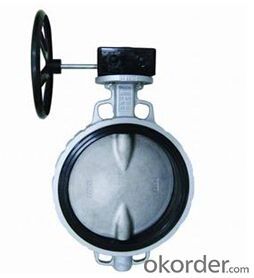

Butterfly Valve DN80 Turbine Type with Hand Wheel BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required.

2.Main Features of the Manual Wafer Butterfly Valve

1. Small in size and light in weight, easy instillation and maintenance. It can be mounted wherever needed

2. The material of valve body: cast iron, cast steel, cast stainless steel and so on.

3. Pressure grade: 1.6Mpa, 4.0Mpa, 6.4Mpa

4. Connecting type: flange coupling

5. Temperature range: normal temperature -20---230ºC the thermal slug type -60---450ºC

6. Operation form: automatic open or close

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

Size: DN50-DN1000

End flange: ANSI B 16.1,EN1092,AS2129

Face to face: ANSI B 16.10

Top flange: ISO 5211

Normal pressure: PN1.0/1.6MPa(150/200PSI)

Body: CI/DI/WCB/ALB/CF8/CF8M

Disc: DI/ALB/Rubber lined Disc/1.2501/1.4529/CF8/Hastelloy Alloy/Monel

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:I think I have a bad valve steam seals because when I start the car white-grayish smoke comes out of the back of the car. When let sit for 2 or more hours start car and smoke comes out everytime. Will a valve adjusment fix the problem? Thanks

- Well, it can only get from bad to worse, costing double as much everytime. For now if you leave it, you will need to top up your engine oil very often, and your fuel consumption will become higher as engine friction is higher and ignition sealing is poor (high blowby gases). This means also lower efficiency of the vehicle. If the weather is hot, the engine will have a higher probability of overheating after operating for long periods of time (say 3 hours or so).... but the real danger is if you keep it this way, your crankshaft and connecting rod bearings will start to scuff little by little, which might cost you a very heavy engine overhaul. My advice: send it to a technician now, as it will require special tooling to tighten the cylinder head, remove/install valve springs, and maybe some shim calibration if it is an old model. Valves must also be inspected, and their guides as may have worn out. Give to specialist, I say, unless you have the patience and spirit to experiment.

- Q:Hi My sons car has alloy wheels, and metal valve stems, there is a tiny leak between the valve stam and the alloy on one wheel, we are struggling to get anyone to repair at a reasonable cost. Would tyre weld make a permanent repair?. Some tyre specialists won't touch the wheel, one other wants to drill out the stem put in another, which sounds a bit drastic. Any other ideas?, is it feasible to get the metal valve stem replaced by a rubber version?. Apparently the metal ones get curbed and then start to leak.

- The leak is caused by corrosion of the alloy wheel in the hole that the metal valve stem goes through. You might try to let the air out and loosen the nut on the valve stem and spray penetrating oil on the o-ring which is on the base of the valve stem and is what holds the air in. Turn the stem back and forth a bit to mave the corrosion and then respray the o-ring. Tighten the stem nut, inflate the tire to 35 lbs. and spray a bit of soapy water on the stem to check for leaks. If it still leaks you will need to remove the tire and valve stem,clean the hole and surrounding area inside the rim and clean the valve stem and replace the o-ring. If the valve stem is a pressure sensor type for the tire air pressure monitoring system you may need to reprogram it. Only use plastic caps on the valve stem. Metal ones corrode on the stem and wreck them and never come off.

- Q:hii have just found out i have a genetic disease called multi valve prolapse but i want more info about itwhat are the symptoms? can it kill me? any info will help!!thank you

- Do you mean Mitral valve prolapse? The mitral valve helps blood on the left side of the heart flow in one direction. It closes to keep blood from moving backwards when the heart beats (contracts). Mitral valve prolapse is the term used when the valve does not close properly. It can be caused by many different things. Most people have no symptoms, but some people have chest pain, a rapid pulse, awareness of heartbeats, migraine headaches, fatigue, and dizziness. In a small number of cases, the prolapse can cause blood to leak backwards. This is called mitral regurgitation. Mitral valves that are structurally abnormal can raise the risk for bacterial infection. Some forms of mitral valve prolapse seem to be passed down through families (inherited). Mitral valve prolapse has been associated with other genetic disorders.

- Q:i have a puegeot 306 turbo diesel and apparently removing the EGR valve helps with engine noise and the smokeyness of the car. Is there any downside to removing it?

- yep good gas milage

- Q:When i was 14 I was diagnosed with a moderate aortic bicusspid valve. I am now 19 at my first cardiologist appointment I was still at moderate. Three months later when i went back in I was rediagnosed with a severe aortic valve. I have every symptom, and I'm getting ready to have it repalced. My question is what am I to expect after surgery. Will i be able to work if not is there anything I can do to have some sort of an income comming in?

- You will be fine. The replacement valves last for a very long time and give you great performance. I assume that you haven't yet started to experience heart failure. If the heart is in good condition then the chances that you'll have a completely normal life are excellent.

- Q:There has been brake fluid leaking below where the Master Cylinder was and pinpointed that the leak was at the base where the steel lines and proportional valve intersect(kinda sprays out out like if a seal is bad or someone didn't tighten enough). Any way to fix this or replace? Vehicle is a 1988 Plymouth Reliant (2.2 liter) Auto, no ABS.

- If you are not familar with brakes I wouldn't suggest tackling this job yourself. You will need to take the line off in question to condemn either the prop valve or the line. I have never in my life seen the line itself leak but I guess it's possible. The valve is a dealer item only, whatever you do, dont buy it from a junk yard. After replacing the valve, if that is what the problem is, most likely you will need to get a brake power bleeder to get all the air out of the system. I would estimate through a shop and the typical mark up on the part, shouldn't be more than 200-225 parts and labor including the brake flush, good luck.

- Q:What are the function of reed valves on a motorcycle?

- They allow a fuel/air mixture to enter the area under the piston in a two stroke engine on the compression stroke, as it is a one way valve when the piston is coming back down the gases are forced up through the tranfer ports into the combustion chamber.

- Q:I have this air canister i want to attach to a homemade Airsoft gun. (please no comments or answers on that).The air canister has an opening on both ends. I thought for simplicity, put a filler valve on one end and a connection to the gun on the other.Exactly what kind of one way filer valve will i need, most of the ones i look at look like propane tank connections and those are for filling and dispensing into the system.

- www.okorder /

- Q:Help! I've got this leaky CPVC valve in a new plumbing setup for a water heater. It only drips when open. :( It's going to be a real pain to replace it. Is there any way to tighten this thing up? It looks like there is a plastic pop off panel on the knob for the valve but I'm not sure. Thanks for any help!

- Turn off the main water to your house. Turn that valve to open. Then tighen the nut on it (slightly), see if the valve will close , if yes; then tighten it a little more, then see if the valve will close. If yes - that should do it. If the nut is so tight that the valve will not close, then loosen the nut just a tad. That should do it, ......... now, turn the valve off. Turn back on the main water to your house -- and see if that works.

- Q:how do you adjust the hyd. valves when motor is running?? thanks, jerry swain

- The adjustment is a mess if you don't have the clips that go on the rocker arms to stop the oil from splattering all over the place. If you want to try it without the clips, then you simply use a socket on each rocker lock nut and back the nut off until the valve starts to click, then tighten the nut back down until the rocker stops clicking then turn it an additional 1/2 turn. Its much easier to adjust the valves to zero lash without the engine running. to do that, follow the adjustment procedure in any Chilton or Haynes manual to put the engine at either TDC or BDC and adjust the valves in the sequence that is specified. Zero lash essentially means you can't move the pushrod up or down when the rocker is tightend down to the point where all freeplay is removed. I'd recommend duing the zero lash adjustment rather than adjusting them with the engine running hope that helps

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve DN80 Turbine Type with Hand Wheel BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords