Butterfly Valve DN500 BS5163 Made in China Britain Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

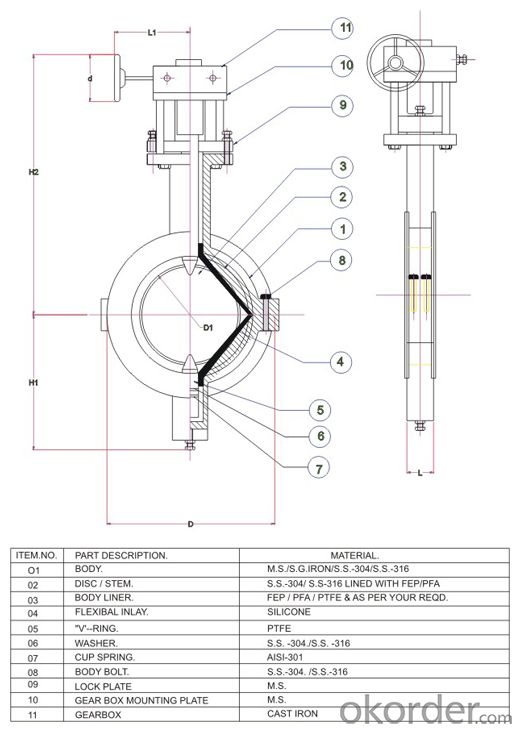

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

1)Size: DN40-DN1400

2)Material:body-CI/DI/WCB/SS

disc:DI/CF8/CF8M/C95400

3)Professional Maufacturer for more than 10 years

PRESENTATION:

1) Sizes:

DN40mm-DN1400mm

2) Materials:

a) Body: CI(cast iron ,GG25 )/ DI (ductile iron ,GGG40)

b) Disc: DI / CF8 / CF8M / C95400

c) Seat: EPDM / NBR / TEFLON / VITON

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:What does "D41X-16" mean?

- GB case, D is butterfly valve, 4 is flange connection, 1 refers to the midline structure, X is sealed form for three yuan, ethylene propylene rubber seal, and 16 is the pressure of 16 kg.

- Q:Import electric butterfly valve which brand is more reliable?

- Recommend Sichuan Ding Heng petroleum machinery company sales agent SPM butterfly valve and FMC butterfly valve, we are partners for many years, have been working together are very happy.

- Q:Why use special flanges for butterfly valves?

- Because to use special flange butterfly valve butterfly flange diameter is just the butterfly inside diameter of DN coincides with a slot in the back, and this is the connection of the steel pipe is inserted into the slot, so as to ensure the sealing effect, but with a flange piece of ordinary cannot guarantee the effective sealing effect.Butterfly valve plate installed in the direction of the diameter of the pipe. Butterfly valve structure is simple, small size, light weight. Consists of only a few components. The utility model can be rapidly opened and closed only by rotating 90 DEG, the operation is simple, and the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the butterfly plate thickness is the only resistance when the medium passes through the valve body, so the pressure drop produced by the valve is very small, so the flow control characteristic is better.If the butterfly valve is used as a flow control, the main thing is to correctly select the size and type of valve. Butterfly valve structure and principle, especially suitable for making large-diameter valves. There are two kinds of butterfly valves commonly used: clip type butterfly valve and flanged butterfly valve. The clip type butterfly valve is a double headed bolt connecting the valve between the two pipe flanges. The flange type butterfly valve is provided with a flange on the valve, and a bolt is used to connect the flanges at the ends of the valve to the pipe flange.

- Q:What is the D37-10Q butterfly valve?

- The model is too simple, right D37A1X-10QB1, D: valve, 3: turbine head, 7: on the vertical plate clamp, A1: type A, X: type of rubber seat, 10: nominal pressure valve Q: is ductile iron, B1: plate is made of ductile cast iron

- Q:Gate valve, butterfly valve and so on can do the valve so that?

- Yes, but the accuracy of the adjustment is not high. Just about. To adjust the flow, please use flow control valve.

- Q:I have a good set of #142 Pontiac heads with small diameter valves. I want to have the heads enlarged to accept the larger Pontiac valves, and I have the larger exhaust valves out of #13 heads and the larger intakes from 6X8 heads. The valves appear ok and shiny on the stems

- If the valve is burnt there is no longer something you're able to do with it yet replace it. in the event that they simply desire cleansing up you could lap them in with a lapping compound the threat with this is which you would be able to desire to visual exhibit unit which you don't get close to to the sting of the valve, this is once you will finally end up with a burnt valve. The valve should not be flush with the valve seat this is plenty to close and the warmth of combustion could have an more advantageous effect on the textile.

- Q:Butterfly valve in the use of the difference? Caliber?

- Role of butterfly valveButterfly valve is to use disc type to open and close parts reciprocating reciprocating about 90 degrees to open, close or adjust the flow of medium valve. The butterfly valve has the advantages of simple structure, small volume, light weight, material consumption, installation of small size, the driving performance of torque is small, simple operation, rapid, high chemical corrosion, and can also have good flow control function and closure characteristics, the use of butterfly valve is very extensive. Its varieties and quantities are still expanding, and the development of high temperature, high pressure, large caliber, high sealing, long life, excellent regulation, as well as multi-function development of one valve. Its reliability and other performance indicators have reached a high level. Disadvantages, there is a certain resistance to the medium.Gate valves are more used in steam pipes and large diameter water supply pipelines, because of the general requirements of fluid resistance is small, the use of gate valve.Valve is hand wheel rotation, stem upward movement. Flow is not the same, the gate valve requires full open. Need a higher installation space, the valve sealing surface has a certain self sealing capacity, its spool by the media pressure closely with the valve seat sealing surface contact, to achieve tight leakage. Wedge gate valve spool angle is generally 3~6 degrees, when forced to shut down excessive or temperature changes of the valve core is easy to die. Therefore, high temperature and high pressure wedge gate valve, in the structure have taken certain measures to prevent spool stuck. The valve in the opening and closing valve and valve seat sealing surface contact and mutual friction is always so easy to wear sealing surface, especially in close off the valve, the valve before and after the great pressure, sealing surface wear is more serious.

- Q:Gate valve and butterfly valve which is installed when there is a direction?

- There is no direction when installing the valve. The butterfly valve has an eccentric butterfly valve which is in the direction of installation

- Q:Butterfly D371X5-16ZB1 what does each letter stand for?

- Daily valve pressThe regular model is out of step with you. I can only explain the regularD371X5-16ZB1D is butterfly valve3 is the turbine drive7 is the clamp connection1 is the display opening signX is a rubber seal16 is 16 kg pressureI don't know the other superfluous letters

- Q:How to calculate the size of the manual butterfly valve?

- 1. The size of the installation fits only two: the length of the structure and the distance between the flanges.2, butterfly (Manual butterfly) butterfly plate installed in the pipe diameter direction. In the butterfly valve body cylindrical channel, the disc shaped butterfly plate revolves around the axis, the rotation angle is 0 degrees -90 degrees between, when rotates to 90 degrees, the valve opens the card completely. Butterfly valve structure is simple, small size, light weight, only by a few parts. The utility model can be rapidly opened and closed only by rotating 90 DEG, the operation is simple, and the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the butterfly plate thickness is the only resistance when the medium passes through the valve body, so the pressure drop produced by the valve is very small, so the flow control characteristic is better. Butterfly valve has an elastic seal and metal seal, two types of seals. Resilient sealing valve. The sealing ring can be mounted on the valve body or attached to the periphery of the disc.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve DN500 BS5163 Made in China Britain Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products