Butterfly Valve DN200 Wafer Type BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve.

2.Main Features of the Manual Wafer Butterfly Valve

1.Square and short neck. Easy to stick scutcheon and cost saving.Nominal bore mm 20 25 32 40 50 65 80 100 125 150 200

2. The material of valve body: cast iron, cast steel, cast stainless steel and so on.

3. Pressure grade: 1.6Mpa, 4.0Mpa, 6.4Mpa

4. Connecting type: flange coupling

5. Temperature range: normal temperature -20---230ºC the thermal slug type -60---450ºC

6. Operation form: automatic open or close

7. Flow characteristic: equal percentage, linearity

8. Leakage: single-base valve: 0.01* rating Kv

9. double-base valve, sleeve valve: 0.5%* rating Kv

10.Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

11.Soft seat. Replaceable. Increase of service life.

12.Double half shaft without pin.

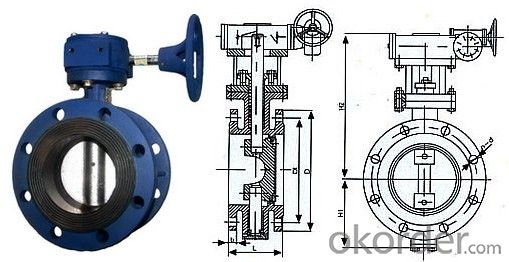

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:I have a D16Z6 SOHC VTEC engine in my 93 Honda Del Sol.Ive been told that the D16Z6 came with 2 different valve covers. One style cover says Honda on the top and another also says VTEC.I have the one that just says honda but I want the other put on.What would I need to swap them, and where would I get them?and a roundabout price

- there okorder

- Q:I need a bit of help. I am trying to find the location of the EGR Valve on a 1992 Chevy Cavalier 2.2L. If anyone can help me out by posting back a picture or diagram that would be great. I found all the text directions, but did not find that to be helpful.Thanks,

- Egr Valve Location

- Q:My Dr placed me in the care of a cardiologist who ran some test and an echo scan reports i have a leaking valve but she failed to tell me which one and i failed to even think to ask. What are the results of leaking heart valves? I asked my mother and she says each one has a different result. What are they? Any help would be great. thanks.

- All of them equal greater stress on the heart, because if blood leaks in, then the heart fills somewhat beyond capacity and causes it to become stressed in the process of contraction.

- Q:Need some info. Ok, four valves per cylinder is better than two valves per cylinder. Fine, why did Ford REVERT to only 3 valves (my guess is to save cost SOHC)? Audi and VW are using five valves per cylinder on some cars, does this offer any advantage over a four valve engine? Maserati even experimented with a six valve per cylinder!!!! (see link) http://www.maserati-alfieri .uk/alfier... but abandoned it (my guess is cost again?) Why are we stuck at four valves or would more valves actually render more horsepower? Pop some ideas best answer to reasonable answer...

- Think of an engine as an air pump - obviously, we want the least amount of restriction for the incoming air and also the least amount for exhausting the compressed air. The ideal situation would be to remove the head during the intake stroke and put it back on during the compression stroke, but, obviously, this isn't possible. On a naturally aspirated engine, the intake is the most critical because the air is moved only by a relatively small difference in pressures. The exhaust stroke, on the other hand, is aided greatly by the super heated temperature and rapid expansion of the gasses. Two intake and one exhaust valve seems to be the most practical and efficient solution - adding more vales means smaller valves and an increase in the overall complexity. I seriously doubt that Maserati ever abandoned ANY automotive idea due to cost restraints. It's far more likely that adding more valves than three or four simply resulted in diminishing returns. Sometimes the allure of a new buzz phrase is nothing more than a marketing ploy - a 16 valve, DOHC, four cylinder engine, for example, is a pretty impressive resume for an engine, regardless of whether it actually is the optimum performance set up or not.

- Q:The hot water shutoff valve to the washing machine was dripping. I removed the packing nut and put in new packing over the weekend. Problem is that the packing nut seems to only go back on at an angle no matter what I do...it may have already been that way though. The valve isn't currently dripping, but I'm not liking the way the packing nut only goes on at an angle. Would it be crazy to keep the existing valve if I keep an eye on it and over time it doesn't drip, or is it too risky to keep this valve given that the packing nut is on at a funny angle? (Local plumbers here in Northern NJ all want around $350 if I were to replace both the hot and cold with a watts single handle valve.) Thanks, J.

- It is your house if your uncomfortable with the packing nut being cross threaded then have it replaced otherwise if it isn't leaking just keep an eye on it. by chance do you turn your water valves on and off alot? because if you do you are causing the packing to deteriorate.

- Q:I was looking at the specs on my audi a4 and it said 30 valves and I was looking at a few other cars and they said 24 valves. What do the valves determine? Whats the difference if the car has more valves than another?

- Valves let the air and fuel in and the exhaust out. Number doesn't matter much, seeing as some valves are bigger than others and overall what really matters is the bottom line which is power and efficiency.

- Q:My brother is 32 years old.He has an enlarged heart ,a murmur,high blood pressure and heart regurgitation.He may be having the valve replacement surgery.I was wondering if anyone has had these things wrong with them and had the valve surgery and did well afterwards.Any information would be very much appreciated.

- Which valve is getting replaced (there are 4 in the heart)? Will he be getting a man made one (which will require life long blood thinners but are also very durable) or a pig valve (no need for blood thinners but won't last as long) ? Many people get valve replacements and it makes them feel wonderful afterwards.... make sure you find out about exactly the surgery he's having so you know... but I'm sure he'll be fine.

- Q:pls. tell me the differnce between isolation and block valves and also where it to be used .

- *Terminology okorder /

- Q:I have a '98 Dodge Caravan 3.0 and the valve cover gasket is bad. How do I replace it?

- you are going to not like this first drain coolant 2 remove the throttle body linkage remove the pipe going to the egr to exhaust manifold [helps to use penatrating oil] remove assorted hoses to get to removing the upper intake plendeum {not the lower intake] [you need to put a shop towel over the open intake ports at the engine to keep any and all debries out of the intake ports to the engine] you should be able to see the valve covers by now remove the valve covers bolts remove the valve cover clean the gasket surfaces on the cylinder head [don,t leave ant debries in this area or in the valve cover [cleanlyness is a really good thing at this point in the build keep the crud out] there are some half moon seals that need to be replaced at this time located on the ends of each cylinderhead put a light bead of RTV high heat silicone on the rounded side of the seals and install the seals in thier half moon bores the RTV high heat silicone will kinda squish out of the seal don,t let the beead get carried away wipe of the sealent with a clean towel [shopcloth] not paper towels put a little RTV high heat silicone across the seal s flat side wipe flat with your finger install the valve cover gaskets on the valvecover [a little automotive contact cement for weaterstripping helps hold the gaskets reinstall everything fill coolant system change the oil and filter look for leaks a book or parts guy should be able to help find the right touque to tighten the bolts remember cleanlyness works here good luck should take about 8 to 10 hours note do not reuse any gaskets any where new hoses would not be a bad idea along with a thermostat ihawk3

- Q:Cylinder head valves.Can't really differentiate the difference between burnt and just carbon build up on valves. Are they the same?If I the valves have no cracks or holes, can I clean the carbon off of them and reuse them.If they don't leak when I re-leak test them, are they then good to use?Had very little compression in one cylinder.What cleaner is safe to use on the valves?I know I should replace all, but any money I can save right now, helps a lot.Also I seen a method of re-lapping the valves by using a tool (stick with a suction cup on end that sticks to valve surface) that you spin while valve is seated. It refinishes the seat and recreates the seal/re-laps. Appears to work and seal just fine. Anything really wrong with this method?

- If the valve is burnt there is nothing you can do with it but replace it. If they only need cleaning up you can lap them in with a lapping compound the danger with that is that you need to watch that you do not get close to the edge of the valve, that is when you will end up with a burnt valve. The valve should not be flush with the valve seat that is way to close and the heat of combustion will have a stronger effect on the material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve DN200 Wafer Type BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords