Building Hoist Single SCD200 Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist Single SCD200

CounterweightThe P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device, and the composition and function of each major part can be described as below:

1. Metal Structure

The metal frame is composed of: cage, mast, base frame & enclosure, anchorage and etc. The surface of these metal structures can be spray-painted and hot galvanized according to customers’ requirements.

Cage is of the main running & transporting part, whose dimension and shape can be customized according to the factual site condition. Entrance & exit doors can be produced as up & down sliding or ramping model for safety and convenience. Every set of P/M hoist can be equipped with single or double cages. The entrance & exit doors and the wall of the cage can be produced with steel net, perforated steel board or aluminum plastic board. The floor and ceiling parts can be produced with steel board. On the top of the cage, there is a trap door with 0.25 m2, equipped with the limit switches. When testing and repairing, workers can climb up to the top of the cage through the ladder inside the cage. When emergency happens, the trap door can be used as exit. There are hand rails installed on the top of the cage, protecting workers from falling.

In addition, the hoist can be equipped with driving cab and rebar carrier device according to the customers’ requirements.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

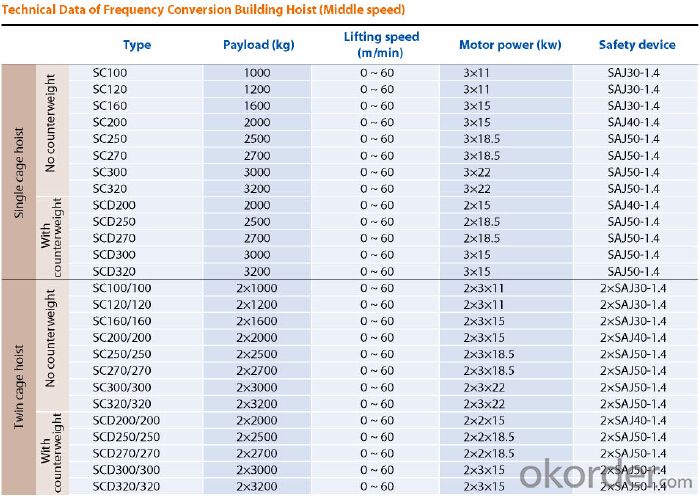

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q:6 layer of brick and concrete construction project, have tower crane still need construction elevator?

- Tower crane is used for heavy lifting, long pieces, small machinery and materials must be used in the construction elevator.

- Q:Can a construction elevator use a single cage

- Can use single hanging cage, an accident is a management issue could not be struck down so many people, if such construction lifter dual-use goods elevator belongs to the people, 19 people find this elder brothers say batter to death then top with manned elevator nor safe, in fact is a regular inspection, site do not have an accident can only say that the site is too lax

- Q:How does the elevator operate

- The application of the construction elevator has gained popularity over the years, and has attracted many employees. The construction elevator is a highly skilled industry, so it is required that the professionals must master certain expertise. Here is a knowledge of how to operate a lift machine, hoping to help you.

- Q:How many people are there for construction workers

- At the end of the 20th century, the elevator was powered by the permanent magnet synchronous towing machine. It greatly reduces the space of the machine room, and it has the advantages of low energy consumption, energy efficiency and speed, which has greatly contributed to the development of real estate. Thyssenkrupp elevator company has developed a new type of "multiple lift" that can operate vertically. Take the size of a common car The size of the escalator is quite different: but the total area is required in the national standard. Give you a general calculation The width of the well is the width of the car. Well, the depth of the well = the car depth + 600 (for the reside) The width of the well is the width of the car. Well, the depth of the well = the car's depth + 1200 (for the rear-end). The u-shaped tourist ladder is usually around 1000kg The car is usually about 1300x1800 The steel structure shaft is width between 2200 and 2400, depending on the size of the door. The depth of the structure is about 1500, and the rear wall is empty.

- Q:What is the need for the sc200/200 construction elevator cable?

- The sc200/200 construction elevator cable line should not be below 120 square. Man's ladder 33KW, 5 * 33 = 165KW The tower is 45KW one, 2 * 45 = 90KW The pressure slag welder is estimated to be 25KW Touch welder 1OKW, 5 * 10 = 50KW Other facilities such as mixer, temporary illumination etc. 30KW Total power: 165 + 90 + 25 + 50 + 30 = 365KW One square cable is 5 minus 7A, 380V is 1KW is equal to 2A. That's 730A 730A divided by 5-7 calculates that the cable line should not be less than 120 square.

- Q:How large a leakage protector is used for the construction elevator

- If it is 33KW, direct start, single cage, 160A, leakage action current 50ma-75ma, movement time 0.1 s, electrical machine leakage protector. The best.

- Q:What is the main function of the construction elevator safety guard

- Falling to a certain speed will automatically card death

- Q:There are differences between the construction elevator and the construction elevator

- The principle is different, the construction elevator operates in the litter box. The elevators are short for construction elevators, which are very high in the safety and performance of large facilities that can be used on the site. The construction elevator should be a dual-use lifting device.

- Q:Is the construction elevator the same as the construction elevator

- Construction elevators are often called construction elevators, but construction lifts include a broader definition, and construction platforms are part of the construction elevator series. Simple construction elevator is by car, driving mechanism, standard section, attached to the wall, chassis, fence, electrical system and so on several parts, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction elevator is usually used with tower crane on the construction site, the average load in 1-5 tons, running speed is 1 to 60 m/min.

- Q:Excuse me: what is the meaning of heavy weight in the construction elevator?

- With double cage for heavy, namely SCD200/200 series Is the two cages, each cage has a corresponding weight, the weight up and down in the elevator cage rise to energy conservation and reduce the reaction between the up and down, when you imagine front-rear door principle is about the same

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building Hoist Single SCD200 Counterweight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords