Building Hoist Single SC270 Middle Speed

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist Single SC270 Middle Speed

Driving board

The driving board connects driving unit with driving frame. A rack wheel is installed at its back. Through adjusting the eccentric locking collar of the rack wheel, the clearance between the pinion and the rack can be adjusted to ensure the proper engagement of them( Before leaving our factory, the clearance between the pinion and the rack has been properly adjusted by our engineers), as a result, the cage will run more stable. The connection between the driving board and the driving frame is of float connection, with rubber shim, to reduce mechanical vibration .

Driving frame

The driving frame, bearing all the loading from the cage, is welded with channel steel & steel board and equipped with 6 rollers Inside the roller there is installed eccentric axle and rolling bearing, which can be adjusted separately. The adjustment of eccentric axle will effect the relative position of driving frame and mast. The safety hook is installed on the driving frame, aiming to avoid overturn of the driving frame and disengagement position between pinion and rack. The driving system, as the vital part of the hoist, is composed of the electrical magnetic motors, reducers and driving frame.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

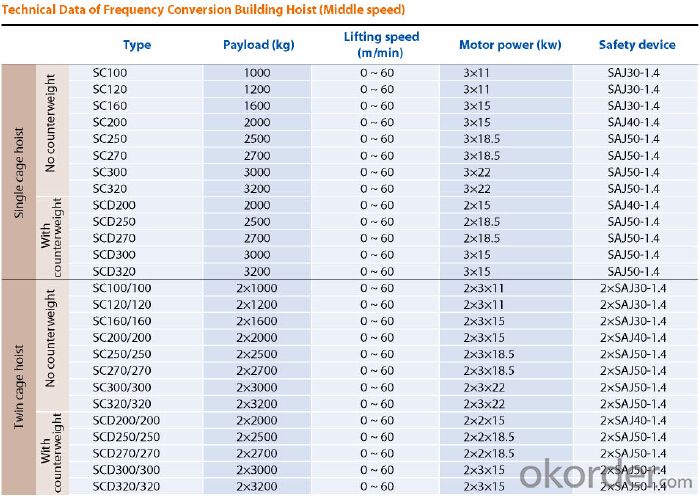

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q:What is the main function of elevator motherboard?

- The elevator motherboard is different from each brand, and it functions like a computer motherboard

- Q:The safety officer shall be responsible for the work of the construction elevator

- (1) the use of dual-use functions of the construction elevator, the installation and removal of the professional personnel issued by the competent department of construction administration shall be undertaken by the professional personnel. The personnel who have passed the training, qualified for the examination and obtained the certificate of the post shall be operated and repaired. (2) the capacity of the concrete base culture cooperation should not be less than 150kPa, the tolerance of 10mm and the drainage facility should be allowed. The distance between the guide bracket of the elevator and the wall of the building should be suitable, and the smoothness should be stable. (3) the lifter is used to control two directions, and the vertical control is 0.05%. Each floor shall have a platform, a passage, a fence and a protective door. No obstacles can be found. (4) the elevator that is installed in a dark place, and the passage shall be illuminated and a floor display lamp and floor number; A closed barrier should be set up in the well. The elevator shall be subject to acceptance by the technical director and the relevant departments, and shall be tested by the crash and shall be used in the rear. (5) in the use of or during the use of the elevators, the manufacturer or designated unit shall conduct the debugging and maintenance and verification. The lifter should undergo a fall test every three months and the fall test should be adjusted when the fall test exceeds 1.2 m. Every time it falls, the receiver should be repaired once.

- Q:For example, what records do you want to have a third party monitoring?

- The elevator overhaul formalities; First report to the local special court, after the approval of the major repair, the major repair unit should have a major repair record to leave the record of party a, including the replacement parts or the procedure that changes. Then the local special inspection hospital will be required to check again.

- Q:How many kw is the sc construction elevator

- There is no fixed standard, which is widely adopted, 3X11KW, which is 33 kilowatts. The power of the motor is determined by the speed ratio of the decelerator. The most common lifter is 33 kilowatt, the speed ratio 1:16, 33 meters per minute.

- Q:Whether the construction elevator is a dual-purpose elevator

- The construction elevator is being operated on; And a person's elevator is automatically controlled; The construction elevator is directed by the rack, which is seen in the rack, and the noise is large. The escalator is not a rack, it is usually guided, and the rails are invisible. Construction elevators are rudimentary; And the elevator is complicated.

- Q:The construction elevator should have those procedures

- Installation and demolition plan, content can guide safe construction, and have complete approval procedure. The installation and demolition of the team must hold the certificate of safety of the above provincial competent authorities. There should be substantial content for the safety of the installation, the demolition of the staff and the safety technology of the driver. Should have basic design, hidden acceptance and concrete strength speech. The inspection and acceptance of the installation completed and the inspection presentation of the competent part. The construction elevator has a record. The elevator is using a copy of the original copy. An employee's special course post certificate. Other relevant safety information. The construction elevator is a larger vertical transport equipment, and the safety and blood lessons of previous accidents are profound. Strict inspection, the key prevention of elevator accidents, is the key link of the safety management at the construction site, and the safety management staff at all levels should be awake and familiar.

- Q:The staff on the construction platform shall not exceed the number of people

- Depending on the actual situation, different quality of platform specifications will affect the number of people manned. Hope can help you.

- Q:Construction elevator positioning should consider which problems

- First make sure that the whole fence can be put down, and there should be no other extension of the fence that does not interfere with the lifting up and down of the cage Considering the length of the wall support, ensure the effective adjustment of the enclosed wall Then consider the installation of the wall support Consider whether access to the building is appropriate Some sites have been put into buildings directly, and some sites have considered scaffolding between them

- Q:The maximum allowable deviation of the vertical is the vertical degree when the construction elevator is installed

- The maximum allowable deviation for the installation of the elevator rail frame is the following: The height of the elevator rail is less than 70 meters, and the vertical deviation should not be greater than one thousandth of the height of the guide frame. 2, the guide frame height is greater than 70 meters is less than or equal to 100 meters, the deviation is less than or equal to 70 mm. 3, the guide frame is larger than 100 meters is less than 150 meters, the deviation is less than or equal to 90 mm. 4, the guide frame is larger than 150 meters is less than or equal to 200 meters. The deviation is less than or equal to 110 mm. The guide frame is greater than 200 meters and the deviation is less than 130 mm.

- Q:Is there any violation of the law after the construction elevator is scrapped?

- In principle, eight years; But for eight years has scrapped section standard of standard section pillar thickness wear to design thickness of 1/4 (like this value) will be scrapped or downgrade use; After eight years, the construction elevator can also be used, but the structural parts need to be broken and the test can be used again. The pendant safety device for the construction elevator is required to be tested every year for five years.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building Hoist Single SC270 Middle Speed

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords