Building Hoist Single Cage for Material Transporting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description:

1. The recommended cage dimension(LXWXH):2.0X1.0X2.5, 2.5X1.0X2.5, 2.5X1.3X2.5, 3.0X1.5X2.5, 3.2X1.5X2.5, 3.8X1.5X2.5, 4.0X1.5X2.5, 4.2X1.5X2.5 etc, we can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to your requirements.

3. The mast and the tie-in surface can adopt paint-spray, or hot galvanizeing processing.

Feature:

There are single cage and double cages hoist. According to the need, getting rid of one cage of double cages-the hoist will be changed to single cage hoist.

SC building hoist is equipped with reliable electrical and mechanical safety device. It is efficient and safety vertical transporting equipment.

FAQ:

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

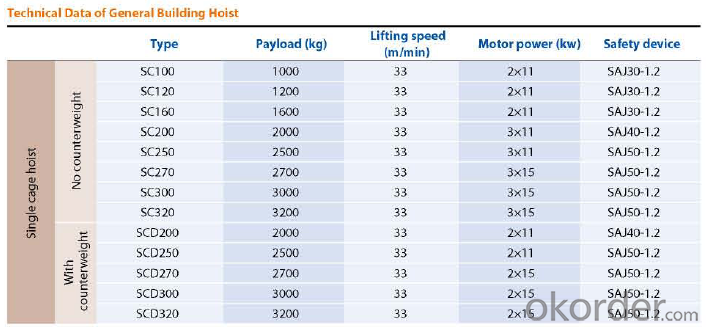

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

In the past 10 years, CNBM has established over 10 manufacturing base, to offer the one-stop services in construction machinery filed, including R&D, designing, manufacturing, quality control and delivery.

Our product has been exported to more than 100 countries with high customer appreciation & brand popularity.

CNBM provides the full series of construction machinery and one-stop overall solution. Our product range covers pre-fabrication including aggregate crushing, dedusting and block making; concrete series including mixing, batching, pumping & placing; construction series, such as tower crane, building hoist, suspension platform and lifting basket; light construction machinery, including compacting, cutting, surface finishing machines & rebar processing machines.

Especially the concrete placing boom, we’re the No. 1 in term of products variety, with top quality placing boom of placing radius ranging from 10 meters to 51 meters over 10 different series, the excellent quality & performance has been tested & approved by being used in lots of world famous high buildings.

The manufacturing base of CNBM adopts 6S management system. Quality control system are implemented strictly in the whole procedures, including components purchasing, fabricating and manufacturing, packing and dispatch pre-inspection, ensuring the perfect quality assurance for all of our products. With international certificates like ISO9001:2008, CE & SGS, CNBM guarantee the international first-class level for all of our products.

“Quality achieves outstanding success, innovation leads the bright future”, our working principle has leads the rapid expansion of CNBM, with branches and spare parts distribution centers established oversea step by step.

In the coming days, CNBM will continue to forge ahead, make our best efforts to create the best platform for career performance, as well as to realize the maximized mutual benefit with all CNBM friends, partners, agents & clients.

“View Broad, Ambitions Boundless”, at a new height, we wish to join hands with all the ambitious friends together, contributing to the consummation of the first-class quality construction machinery industry, and creating the new glory constantly.

- Q:What's going on with the decline in construction lift

- Check whether the brake work is valid.Check to see if there is any problem with holding the brake.

- Q:There are two 18-story buildings under construction and tower cranes.

- In this case, you do not need to install the construction elevator at the main stage. After the main body is finished, install the tower crane, reinstall, mainly for decorate the vertical transport of the stage.

- Q:The safety officer shall be responsible for the work of the construction elevator

- (1) the use of dual-use functions of the construction elevator, the installation and removal of the professional personnel issued by the competent department of construction administration shall be undertaken by the professional personnel. The personnel who have passed the training, qualified for the examination and obtained the certificate of the post shall be operated and repaired. (2) the capacity of the concrete base culture cooperation should not be less than 150kPa, the tolerance of 10mm and the drainage facility should be allowed. The distance between the guide bracket of the elevator and the wall of the building should be suitable, and the smoothness should be stable. (3) the lifter is used to control two directions, and the vertical control is 0.05%. Each floor shall have a platform, a passage, a fence and a protective door. No obstacles can be found. (4) the elevator that is installed in a dark place, and the passage shall be illuminated and a floor display lamp and floor number; A closed barrier should be set up in the well. The elevator shall be subject to acceptance by the technical director and the relevant departments, and shall be tested by the crash and shall be used in the rear. (5) in the use of or during the use of the elevators, the manufacturer or designated unit shall conduct the debugging and maintenance and verification. The lifter should undergo a fall test every three months and the fall test should be adjusted when the fall test exceeds 1.2 m. Every time it falls, the receiver should be repaired once.

- Q:How many meters is the wall of the construction elevator?

- I know the bunter lift is six meters so you can get it

- Q:When does the construction elevator take off?

- Generally in roof waterproof thermal insulation engineering, interior decoration engineering basic completion, outdoor decoration project is approaching to the end, began to dismantle scaffold outside of time.

- Q:How is the construction elevator installed

- Construction elevator installation 1) the location of the elevator depends on the condition of the site and the equipment, so as far as possible, stay away from the overhead line and keep the safe distance specified. When the elevator is running, there is a lot of danger and should be avoided. 2) the order of installation is: 3) place the chassis on the base and the base pre-buried bolt, and the platform is placed on the chassis, and the basket is placed in the middle of the chassis. 4) to install the standard section, each installation of two standard sections (usually less than 8m) to be temporarily fixed. The wire rope shall be used for the use of the temporary cable, and the joints and supporting points shall be bolted and not tied with the lead wire. 5) the installation should alternate between the two columns. Node bolt specification must according to the aperture matching, not packing, found that the aperture position at the time, can not arbitrarily expanding, more can't to lead wire bundle, instead to avoid loose node deformation. 6) when installing the standard section, pay attention to the vertical degree of the guide, and the line of the guide line should not appear in the line of folding and too big clearance to prevent the collision from running. 7) when construction site conditions permit, it can be assembled on the ground and then hoisted on the whole to reduce the height of the work. Due to the design of the frame, the stress condition of the construction is only considered, so before the whole moving up, the counter can be temporarily strengthened to enhance the bending capacity of the nodes.

- Q:When building tall buildings, the machine that USES to lift concrete to wait for tall building

- The concrete pump, which can be raised in a certain radius, is the tower crane.

- Q:Does the building height not exceed 40 meters must install the construction elevator?

- There is an elevator quota in the budget quota, but how many floors can be priced?

- Q:Safety device for construction elevator

- Many 1, 2, upper and lower limit for safety device 3 TDD, extreme limit 4, buffer spring 5, has threshold position switch, single threshold position switch 7, 6 top and limit switch 8 TDD, enclosure door lock 9, lock line 10, has locks There are a lot of electrical safety protection

- Q:The construction elevator always jumps

- Possible causes include: 1, the area that has broken skin in the line, leak the electric trip. There's something wrong with the switch Loose contact points in the line, and bad contact may also jump. It is best to do a thorough examination before closing the lock, and the forced closing is dangerous

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building Hoist Single Cage for Material Transporting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords