Building Hoist SC120/120 New Twin Cage for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist SC120/120 New Twin Cage for Sale

The mast is the force-bearing part of the hoist, also serves as the guiding rail for the cage running. Each mast section is connected with 8.8-level high strength bolts to make up the required height. The mast section, which has superior quality and significant bearing ability, is produced with quality Q235Φ76 seamless steel pipe.

The rack is the major force-bearing part mounted on the mast section, whose material has the same quality with the train wheels, after being tempered and long-time carburized, making it wear-resistant, high-ductile and long life-span.

Cage is of the main running & transporting part, whose dimension and shape can be customized according to the factual site condition. Entrance & exit doors can be produced as up & down sliding or ramping model for safety and convenience. Every set of P/M hoist can be equipped with single or double cages. The entrance & exit doors and the wall of the cage can be produced with steel net, perforated steel board or aluminum plastic board. The floor and ceiling parts can be produced with steel board. On the top of the cage, there is a trap door with 0.25 m2, equipped with the limit switches. When testing and repairing, workers can climb up to the top of the cage through the ladder inside the cage. When emergency happens, the trap door can be used as exit. There are hand rails installed on the top of the cage, protecting workers from falling.

In addition, the hoist can be equipped with driving cab and rebar carrier device according to the customers’ requirements.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

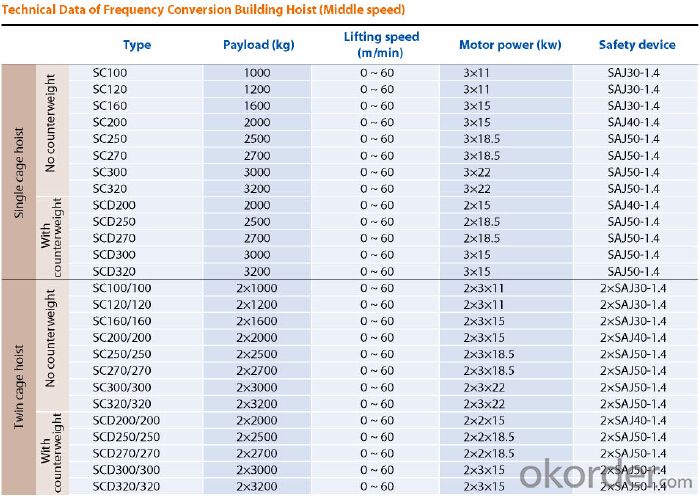

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q:The construction elevator can not operate during the use of several stages of wind power

- 11, when the wind speed exceeds 20m/s and the bad weather, such as hail, not use the lift." I'm a construction elevator This is the norm It's about a six-stage wind by 20m/s.

- Q:Construction site construction elevator and tower crane, which unit security check and acceptance?

- Different but most likely is the construction elevator

- Q:The elevator is banned from using elevators for more than a class of high winds

- More than 6 levels of wind are forbidden to be removed and used. More than 4 levels of wind are not allowed to rise, and more than 6 winds are prohibited.

- Q:Elevator installation approach, need to give the total package (inspect) what data, come a master to answer the detail point

- In ten days: installation company qualification (including business license, qualification certificate, safety production license, organization code certificate and company performance, etc.), installation personnel qualifications (including the principal, special operations personnel, etc.), installation construction scheme (including the construction organization design, safety and civilized construction scheme, construction progress) The installation process: in materials to submit for approval (material inspection report, certificate, etc.), play equipment to submit for approval (mechanical factory qualified certificate, safe use license, etc.) After the construction is completed, the certificate of safety inspection (which needs to be provided by the special security agency)

- Q:How does the driver of the construction elevator do the search for a sudden power failure

- When the elevator in the operation of the midway stop due to power outages or other reasons, the manual can be decreased, the end of a motor brake electromagnet manual release slowly shake handshandle pull outward, slowly slide down the ladder cage, ladder cage fall shall not exceed the rated speed, manually drop must be conducted by professional maintenance personnel.

- Q:The staff on the construction platform shall not exceed the number of people

- Different models have different load rating and platform lift platform size, this depends, suzhou new aluminium alloy elevator, Lin professional aluminum alloy lift platform.

- Q:How long does the construction elevator do a crash test

- For the safety of the crane, the anti-drop safety device must be certified every 1-2 years.

- Q:The construction elevator is commonly used in the process of the project

- The construction elevator is commonly used in the process of the project. It is best to give a time period You're just saying one of its USES, I want to know what is the stage of what is going on in the project

- Q:What is the meaning of double straps in the construction elevator?

- One component of the elevator's drag system is the weight of the car. The other side of the car is connected to the top of the car by dragging a wire rope. It can be used for the energy saving of the elevator towing system, because the elevator load optimization is calculated by the theory calculation. The elevator should be calculated before the weight is weighed: the calculation principle is that the weight is equal to the weight of the car and half the load.

- Q:The construction elevator always jumps

- The starting current is more than three times the running current, and your air switch is low in the maximum current

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building Hoist SC120/120 New Twin Cage for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords