Building Hoist Middle Speed with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT, LC or Cash

- Min Order Qty:

- 1 unit

- Supply Capability:

- 25 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Feature: Building Hoist Condition: New Application: Construction

Payload(kg):2*1000 Lifting Speed(m/min):0~33 Motor Power(kw): 2*3*11

Safety Device: 2*SAJ30-1.4 Cage: Two Counterweight: No

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: SC100/SC100

Packaging and Shipping of Building Hoist

Packaging Detail: Nude Shipping time: 25-30days

Main Parts of Building Hoist

● Adopts the most advanced VF(bothe China and Simens, Schneider are available) speed control device and microcomputer programmable logic controller.

● Nord motor and China famous motor are available.

● There are three different lifting speed: low, medium and high. China famous brand inverter and Siemens, Yaskawa as well as schneider

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

● Hot galvanized mast section and paint-sprey mast section are available.

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist Images

CMAX Building Hoist

Welding Process

Mast Section

Driving Unit

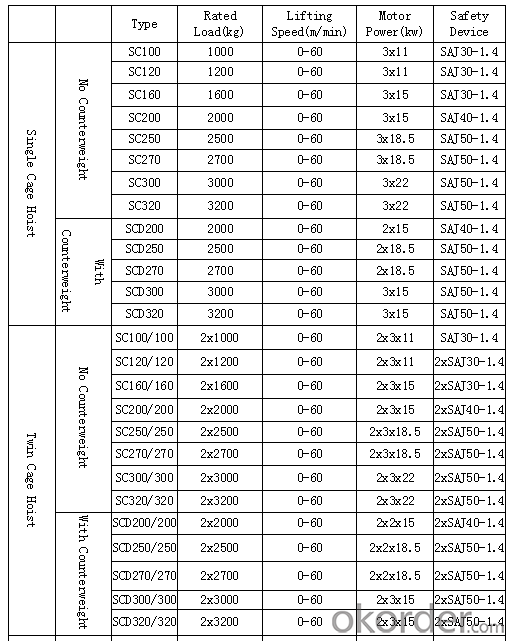

Different Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the usage of building hoist ?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the component building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: How many units of construction hoist can you sell abroad in 2014?

A: CNBM is China-owned manufacturer and CMAX is its brand. In 2014, the exporting amount are 450units.

- Q:How do construction suspension scaffolding be handled in the people's elevator?

- The shelf of the discharge platform is separated from the outer scaffolding and set up separately! Can't connect together

- Q:How large a leakage protector is used for the construction elevator

- The leakage current is less than 30 milliamps The short circuit current is typically 1.2 to 1.5 times the rated current If the motor is rated at 10, it is usually used with a 125-15 leakage protector

- Q:Why is the construction elevator not up to the roof

- The free end of the construction of the lift height is only 7.5 meters high, general construction elevator drive now is the case, so the hoisting cage height and drive around 4.5 meters high, the other national standard construction elevator ceiling limit moves, drive above about 1.8 meters away from the top of the rails. So it's the free end of the construction elevator that can't satisfy the roof. As long as they can set up effective adhesion measures, they can also get on the roof.

- Q:The construction elevator should have those procedures

- Installation and demolition plan, content can guide safe construction, and have complete approval procedure. The installation and demolition of the team must hold the certificate of safety of the above provincial competent authorities. There should be substantial content for the safety of the installation, the demolition of the staff and the safety technology of the driver. Should have basic design, hidden acceptance and concrete strength speech. The inspection and acceptance of the installation completed and the inspection presentation of the competent part. The construction elevator has a record. The elevator is using a copy of the original copy. An employee's special course post certificate. Other relevant safety information. The construction elevator is a larger vertical transport equipment, and the safety and blood lessons of previous accidents are profound. Strict inspection, the key prevention of elevator accidents, is the key link of the safety management at the construction site, and the safety management staff at all levels should be awake and familiar.

- Q:Are there any good signs in the construction elevator door

- Referring to the unified code of construction safety technology of GB 50870-2013, and the construction safety inspection standard JGJ59-2011

- Q:How long does the construction elevator do a crash test

- For the safety of the crane, the anti-drop safety device must be certified every 1-2 years.

- Q:How does the construction elevator add up

- You can use a ready-made high-altitude operating platform and a high-altitude working platform

- Q:What is the meaning of double straps in the construction elevator?

- One component of the elevator's drag system is the weight of the car. The other side of the car is connected to the top of the car by dragging a wire rope. It can be used for the energy saving of the elevator towing system, because the elevator load optimization is calculated by the theory calculation. The elevator should be calculated before the weight is weighed: the calculation principle is that the weight is equal to the weight of the car and half the load.

- Q:Is the construction elevator the same as the construction elevator

- Construction lifter and building construction elevator, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction lifter is usually used with tower crane on the construction site, the average load in 1-3 tons, running speed is 1 to 60 m/min. There are many kinds of elevators in construction, there are no two kinds of weights and weights in the way of operation, and they are controlled by manual control and automatic control. You can also add inverter and PLC control modules as needed, and also add floor calling devices to the peace layer. The structure principle and characteristics of construction lifter: construction lifter for meet the needs of the lean construction bridge, chimney, etc, it according to the building shape, install the guide frame tilt, and hanging basket level, along the inclined guide plane running up and down.

- Q:The construction elevator always jumps

- The starting current is more than three times the running current, and your air switch is low in the maximum current

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building Hoist Middle Speed with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT, LC or Cash

- Min Order Qty:

- 1 unit

- Supply Capability:

- 25 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords