Brown Film Hardwood Core WBP Glue Film Faced Plywood for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

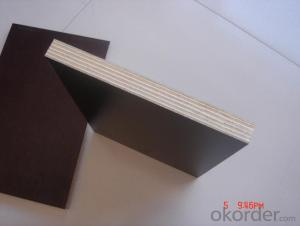

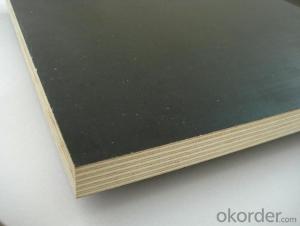

Item Name:Film Faced Plywood/Shuttering Plywood

Size:1220x1440mm,1250x2500mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,other thickness as requested

Description

Item | Film Faced Plywood | |

Face/back |

black film or brown film,logo available | |

Core Material | poplar,hardwood,combi,finger jointg board,etc. | |

Size(mm) | 1220x2440, 1200x2400, 1250x2500, 1830x915,610x2440,etc. | |

Thickness | 9mm 12mm 15mm 18mm 21mm | |

Grade | One time hot press, two times hot press,three times hot press | |

Length(width) tolerance | 1mm | |

Thickness tolerance | +/-0.5mm or +-1mm | |

Glue | WBP(phenolic), MR, WBP MELAMINE | |

Mositure content | 8%-16% | |

Main market | Saudi Arabia,South America,Africa,Europe, India,Southeast Asia,South Korea,Thailand,etc | |

packing | Inside:pallet is wrapped with 0.2mm plastic bags; outside:pallets are covered with caton paper or plywood ,and then PVC/steel tape for strength | |

Loading quantity | 20GP | 8pallets/20M3 |

40GP | 16pallets/42M3 | |

40HQ | 18pallets/55M3 | |

Usage | Widely used for concrete formwork,shuttering work,construction,truck flooring,etc. | |

Minimum Order | 1*20GP | |

Payment | T/T or L/C at sight | |

Delivery Time |

10-30 days according to order quantity | |

Features

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they are very light, our film faced plywood is convenient for transporting, and only one per-son could delivery single formwork by hand.

2. Easy To Cut: the plywood is easy to cut, so according to the construction, the formwork could be cut into the required size.

3. Re-used: film faced plywood could be used 8-10 times.

4.Multi Using: film faced plywood could be used for wall, slab, column, beam and bridge concrete pouring etc.. phenolic film plywood

5. No Deformation: film faced plywood is also whole but not deformation and chipp-ing after 72 hours cooking in boiling water.

FAQ

1.What's your company property ?

More than 10 factories to meet your various needs.

2.Free samples ?

Samples are free. As for the cost of courier , we will give back to you in the payment of the trial order .

3.What's your delivery time ?

The goods will be deliveried wthin 15 days after recepit of the deposit .

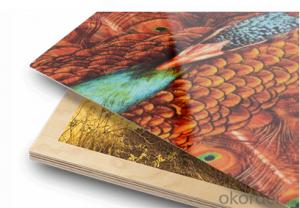

Products Photos

- Q:What are the allowable quantity differences in printed packaging materials?

- Large areas of the current general offset printing, letterpress printing and other printing methods, the size of the largest paper size, the entire area of more than a full sheet size, it is limited by mechanical equipment. Screen printing can be a large area of printing, screen printing products today can reach up to 3 meters x 4 meters, or even higher significantly.

- Q:What are the materials used in screen printing?

- The range of screen printing applications is very extensive. In addition to water and air (including other liquids and gases), any object can be used as a substrate. Some people have evaluated silk screen printing as saying: "if you want to find the ideal printing method on the earth to achieve the purpose of printing, it is probably screen printing method.".

- Q:What's the printing process for PC material? Is the print content on PC or other surfaces?

- As a screen printing material, semi automatic screen printing machine for printing or anti India, in particular circumstances, is usually anti India, India will.

- Q:Carton printing process and materials

- Direct offset corrugated carton process, corrugated box direct offset printing technology has been relatively mature in foreign countries, it is corrugated cardboard directly in a special offset printing press. The utility model is suitable for processing thin corrugated boxes.This process can ensure the formability of the carton, and can complete the fine printing paper printing machine, but the price is more expensive, and the requirement of our country standard is not suitable, not suitable for carton industry to adopt in the near future, but in the next few years, the process may become China's high-end a new direction for the development of carton printing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Brown Film Hardwood Core WBP Glue Film Faced Plywood for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords