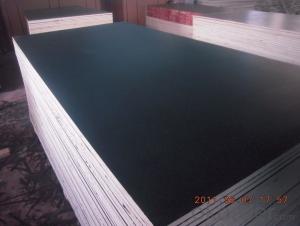

Brown/Black Film Faced Plywood Shuttering Plywood WBP Glue Construction Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specification:

Item name:Black/Brown Film Faced Plywood

Size:1220*2440/1250*2500

Core: poplar/hardwood/combi/birch

Glue: WBP, melamine, phenolic

Description:

| Marine plywood/Film Faced Plywood | ||

| Film | Brown film, Black film | |

| Core | Poplar, hardwood, pine and others | |

| Glue | WBP,Melamine,MR | |

| Size(mm) | 1220*2440, 1250*2500, or requested by customers | |

| Thickness(mm) | 6-27mm | |

| Density | >550-650g/CBM | |

| Moisture | 8-12% | |

| Modulus of Elasticity | >6000Mpa | |

| Modulus of rupture | >30Mpa | |

| Quantity | 20GP | 8 pallets/21M3 |

| 40GP | 16 pallets/42M3 | |

| 40HC | 18 Pallets/53M3 | |

| Min Order | 1*20 ft container | |

| Payment | T/T or L/C at sight | |

| Delivery time | Within 2 weeks after receiving deposit or Original L/C at sight | |

| Addition | Sample available | |

| film faced plywood pictures | ||

Features:

1. The face should be of high resistance to corrosion and moisture.

2. The face should be smooth and easy to take off from cement and easy to clean.

3. The core should be water resistant and won’t swell.

4. The core should be strong enough and won’t break.

5. The edge should be sealed and water proof.

Advantages of our film faced plywood

1. Above 18mm thickness film faced plywood , could be used 20 time at least

2. The inside each veneer is whole core

3. Each veneer is glued totally

4. Boiled for 10 hours , will not cracking

5. Twice hot press to strong joining capacity

6. Cold press again to strong joining capacity

7. 100% Dry

8. We have another glue making factory

FAQ

A. Quality :

With the skilled worker ,mature technology and ten years experience ,all our plywood are steady quality .

B. Price:

Due to the skilled worker ,mature technology and an experienced operating system , we can

quote you competitive price , so that you will have the price advantage to capture your market.

C.Service:

7*24hours , if any need, you can email or call us,we will do our best to meet your demand

D.Export experience:

Over ten years experience for exporting ,We are much familiar with

the export operation .

- Q:What is the density of plywood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material,

- Q:What is the composition of the plywood?

- Glue plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression.

- Q:Plywood is a common material for furniture?

- The usual length and width specifications are: 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on. The main tree species are: camphor, willow, poplar, eucalyptus and so on.

- Q:triple? Nail gun Self-tapping screws? Cork Or other?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q:The density of the plywood is greater than that of the same kind of wood

- As the plywood from the criss-cross the preparation of the veneer, the thermal conductivity is lower than the same species of wood

- Q:Now what is the market for plywood development?

- has also been greatly improved in the international market more and more competitive. China is not only a large veneer export, or the world's largest plywood producer.

- Q:Judging wood is the standard for plywood

- If you have an old piece of furniture, it is time to polish or throw it away, then you can make a decision by identifying the wood sometimes.

- Q:Commonly used plywood, pallets and so on

- straw and other things containing wood fiber, very cheap, so the cost of producing MDF is very low so the market price is cheaper than the solid wood.

- Q:Why plywood is cheaper than solid wood

- commonly known as: multi-layer board) is one of the commonly used furniture materials, is a wood-based panel. Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q:The structure of the plywood at the same time meet two basic principles

- the front panel is called the panel, the back of the table is called the back plate; the core

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Brown/Black Film Faced Plywood Shuttering Plywood WBP Glue Construction Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords