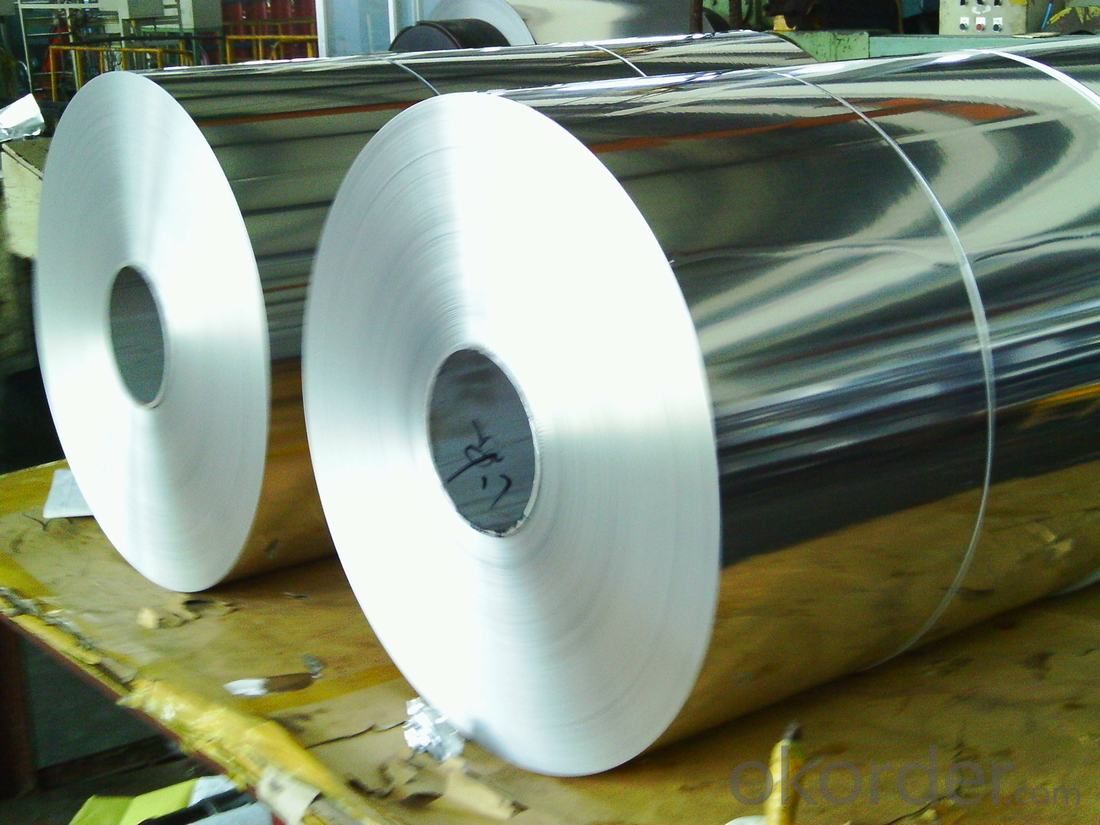

Bright Surface 1100/1050/1020/1060 Aluminum Coils for Lamination

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum Description

-Hot rolling 1100/1050/1020/1060 aluminum coils for roof sheet is used for celling, decorate, ACP,Curtain Wall,Roofing Sheet, PC base, radiator,cookware,deep drawing and more.

- 1 series Aluminum Coils temper: O-H112

-1 Series Aluminum Coils Alloy: 1100/1050/1060/1200/1035/1070

-Thickness: 0.5-10mm

-Width:200-1500mm

-Length:12m Max.

Temper: h14,h16,h18,h22,h24,h26,h32,o/f

Thickness: o.o3mm-3.0mm

Width: 30mm-1700mm

Coating: pe(polyester),pvdf,epoxy

Painting thickness: standard 16-25 mic, max 40 mic

Color: according to ral colors or customer's samples

Packaging & Delivery

| Packaging Details: | Coil ID :508MM Coil Weight : about 2.5 tons or as per customers requirement Packing ; In Export Sea worhty wooden pallets Eye to wall or Eye to Sky One container can be loaded about 20 mts |

| Delivery Detail: | within 25 days after receiving L/C deposit |

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What's the maximum size of 3 mm thick aluminum sheet?

- See tolerance taggingIf there is no tolerance, see the accuracy level of the workpiece and check the tolerance listA 3-4 mm deviation is acceptable if the magnitude is not noted and is of no importanceThat is, the 3.5mm is OK, if the lower accuracy is generally 2.95

- Q:What is an aluminium plate? What is the difference between carbon steel sheet, galvanized sheet and stainless steel plate?What is the order of the price? Thank you

- Aluminized sheet, the full name of aluminum plating, also known as aluminized steel plate, also known as hot dipped aluminum plate.Aluminized steel plate is an aluminum silicon alloy coating steel plate, in which the aluminum content is 90%, silicon 10%. The aluminized steel plate has good heat resistance, heat reflection and corrosion resistance. Its mechanical and physical properties are better than those of cold-rolled steel sheet. Because of the superior performance of aluminized steel sheet, it has been widely used in our daily necessities. Such as car muffler, household appliances and so on.

- Q:AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- Q:Are aluminum sheets fire-resistant?

- Yes, aluminum sheets are fire-resistant.

- Q:Are 101 aluminum sheets suitable for aerospace tooling?

- 101 aluminum sheets are not appropriate for aerospace tooling due to their lack of high strength, stiffness, and heat resistance. Aerospace tooling necessitates materials like high-strength aluminum alloys (such as 7075 or 2024) or even specialized materials like titanium alloys for more demanding tasks. These materials possess superior mechanical properties and can endure the rigorous conditions encountered in aerospace manufacturing.

- Q:there is a magnet for other type of nails except aluminum nails

- sadly, magnets do not work on aluminum, however, the are light enough, to be picked up by a vacuum.

- Q:Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable metal, which means it can be easily shaped and bent without fracturing or breaking. However, the degree of bendability may vary based on the thickness and alloy composition of the aluminum sheet.

- Q:What is the corrosion resistance of aluminum sheets?

- Aluminum sheets have excellent corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface when exposed to oxygen, which acts as a barrier against corrosion. This oxide layer is very stable and prevents further oxidation of the metal, making aluminum highly resistant to corrosion in most environments. Additionally, aluminum sheets can be further enhanced with surface treatments or coatings to increase their corrosion resistance even more. This makes aluminum sheets a popular choice for various applications where corrosion resistance is crucial, such as in the construction industry, automotive manufacturing, and marine applications.

- Q:Are aluminum sheets prone to warping?

- Yes, aluminum sheets can be prone to warping under certain conditions. Aluminum is a relatively soft metal, meaning it is more susceptible to bending or distorting compared to other metals like steel. However, the extent to which aluminum sheets warp depends on various factors such as the thickness of the sheet, the specific alloy used, the temperature it is exposed to, and the level of stress applied to it. Thinner aluminum sheets are generally more prone to warping as they have less structural integrity. Thicker sheets, on the other hand, are more resistant to warping due to their increased rigidity. Additionally, the specific alloy composition of the aluminum sheet can influence its susceptibility to warping. Temperature fluctuations can also cause aluminum sheets to warp. When exposed to high temperatures, aluminum expands, and if not properly supported or restrained, it may bend or warp. Similarly, rapid cooling can cause contraction, resulting in warping. Lastly, the level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can cause the sheet to deform. To minimize warping, it is important to handle aluminum sheets with care, support them adequately during temperature changes, and avoid applying excessive stress. Additionally, using thicker aluminum sheets or choosing certain alloys with higher tensile strength can help mitigate the risk of warping.

- Q:Can aluminum sheets be painted after installation?

- After installation, it is indeed possible to paint aluminum sheets. Aluminum, being a highly versatile and durable material, can be painted for the purpose of improving its appearance or harmonizing it with the surrounding environment. However, it is crucial to adequately prepare the surface before painting in order to ensure that the paint adheres well and lasts long. This typically involves cleaning the surface, eliminating any dirt or debris, and applying a suitable primer to enhance paint adhesion. Once the surface is prepared, various types of paint can be used on the aluminum sheet, such as acrylic, oil-based, or epoxy paint. To achieve the best results, it is advisable to seek guidance from a professional painter or carefully follow the instructions provided by the paint manufacturer.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bright Surface 1100/1050/1020/1060 Aluminum Coils for Lamination

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords