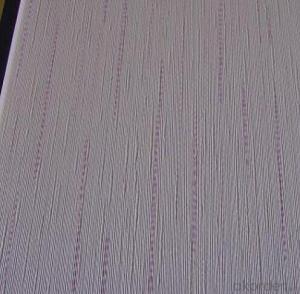

Bright PVC Ceiling Panels With Various Colours

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (PVC Ceiling ) Description

PVC Ceiling Panels

1.Thickness:5-12MM

2.Width:100-300MM

3.Length:It depends,like 5.8M,5.95M

4.Advantage:Economic,Durable

2,Main Features of the (PVC Ceiling )

Main introduction of PVC Ceiling Panels

1.Thickness:5-12MM

2.Width:100-300MM

3.Length:It depends,like 5.8M,5.95M matching with the size of containers.

4.Type: Flat or with a groove in the middle of panels.

5.Contents of PVC panels: normal & popular PVC percentage is 40%, 45%, 50%, 55% or 60%, balance is calcium carbide or other carbonate.

6.Surface treatment:

1)Normal oil printing.

2)Hot stamping.

3)Thermal transferring print

4)Laminated print

7.Surface finishing effect: White / Glossy / High glossy / Gleam etc.

8.Applications:Home kitchen,bathroom,indoor,hotels,hospitals,commercial buildings,meeting room,schools etc

9..Advantage:

1)Economic,Durable.

2)Light in weight and easy to install / assemble with smooth surface,without gap while fixed together.

Available size specifications for customer's checking:

3,(PVC Ceiling ) Images

4,(PVC Ceiling ) Specification

| Width (MM) | Thickness(MM) | Reference Weight(KG/M2) |

| 100 | 9 | 4.25 |

| 160 | 9 | 3.10 |

| 200 | 5 | 1.90 |

| 200 | 6 | 1.90 |

| 200 | 6 | 2.00 |

| 200 | 7 | 2.00 |

| 200 | 8 | 2.75 |

| 200 | 9 | 3.00 |

| 200 | 9.5 | 3.50 |

| 200 | 11.5 | 3.55 |

| 250 | 5 | 2.00 |

| 250 | 6 | 2.00 |

| 250 | 7 | 2.10 |

| 250 | 8.5 | 3.30 |

| 250 | 10 | 4.00 |

| 300 | 9.5 | 3.25 |

| 300 | 10 | 3.25 |

5,FAQ of (PVC Ceiling )

1)Normal oil printing.

2)Hot stamping.

3)Thermal transferring print

4)Laminated print

7.Surface finishing effect: White / Glossy / High glossy / Gleam etc.

8.Applications:Home kitchen,bathroom,indoor,hotels,hospitals,commercial buildings,meeting room,schools etc

- Q:Stainless steel and PVC board can paste no

- Of course Now a lot of doors are made of stainless steel and external PVC board

- Q:its in a place i cannot get to without knocking down a wall and ceiling - is there anything i can pour down the drain to stop the leak at the joint - its a very small drip

- Is there anything you can pour down the drain - no. And if there was I wouldn't recommend you use it - too likely to cause a blockage further along the line. You're going to have to open the wall and get in there and fix it.

- Q:What is the ignition of PVC?

- Ignition means that a substance reaches a certain temperature, it will naturally fire burning. PVC hard plastic products is very difficult to burn, and its spontaneous combustion temperature is 256 ℃, if there is no external fire source, PVC hard products have automatic extinguishing function, it will not help combustion, and self-extinguishing, it is a flame material. PVC characteristics and molding characteristics: Specific gravity: 1.38 g / cm3, molding shrinkage: 0.6-1.5%, molding temperature: 160-190 ℃. Features: mechanical properties, excellent electrical properties, strong acid and alkali resistance, chemical stability, but low softening point. Suitable for the production of thin, wire and cable insulation, seals and so on.

- Q:Pvc board above can stick wallpaper?

- can. The The Smooth surface is easy to paste.

- Q:PVC bathroom cabinet is good

- PVC bathroom cabinet very good. PVC bathroom cabinet with PVC materials and other materials, the use of high-density double-leather process PVC sheet, waterproof performance, high hardness. Using brand hinge and paint track. Scratch, high density, durable. Variety of styles, novel design. Pvc bathroom cabinet is a chemical material board made of bathroom cabinet, material is soft, so pvc bathroom cabinet cabinet light, easy to move. Lens maintenance: Bathroom cabinet lenses appear when the stains, with a soft cloth and neutral detergent cleaning. Bathroom countertops, ceramic care: in use, do not be hard to characterize the table, ceramic pots coated with a neutral detergent wipe with a rag. Bathroom cabinet maintenance: to maintain the air circulation between the bathroom to prevent long-term left in the cupboard moisture, try to keep the cabinet dry. PVC bathroom cabinet surface dust. Dirt, you can use a soft cloth dip soap and water. Weak lotion and warm water to wipe the cupboard, do not use a dry cloth to wipe the cabinet, in the process of wiping the cabinet do not use any grinding effect of cleaning A hard cloth, paper towel, or wire ball to avoid scratching the cabinet surface. PVC bathroom cabinet surface oil. Oil. Lubricant pollution, can be wiped with a soft cloth, after a neutral detergent or ammonium solution or with a special detergent to wash. If the acidic liquid attached to the PVC bathroom cabinet, should immediately rinse with water, and then ammonium solution or neutral carbonic acid soda solution dip, and then neutral washing or warm water washing. PVC surface with rainbow pattern, is too much use of detergent or oil caused by washing with warm water neutral wash can be washed away. PVC surface dirt, available 10 percent of nitric acid or grinding detergent washing, PVC bathroom cabinet can also be used special detergent washing, regular care can extend the life of PVC bathroom cabinet.

- Q:Does the steel pvc board have radiation?

- To figure out what the meaning of radiation material, first of all should understand what is radiation? ??????? Radiation generally contains two concepts: 1, magnetic field discharge or produce static electricity, the impact of signal interference on the human body known as radiation; 2, material composition of trace elements such as heavy metals or gas substances through the absorption of light or air formation of the composition of the damage Also known as radiation, it is generally found in natural materials such as marble, granite or stone processing of paint or tiles. The PVC plastic steel is generally synthesized through the resin, do not need these substances to do raw materials, so it is usually free of radiation!

- Q:Flammability of Polyvinyl Chloride Plastics

- PVC combustion performance is not good, from the fire that is off, the flame was yellow, the bottom was green, white smoke, are flame retardant plastic; burning, irritating hydrogen chloride odor release, softening when burning.

- Q:Gong board, gypsum board and PVC board type, characteristics and role?

- Clasp: Wood Clasp, PVC gusset, aluminum gusset, wide and narrow, different thickness, different colors. Mainly used for ceiling and wall. Gypsum board: 1.2mX2.4m 1.2mX1.5m 1.2mX3.0m thickness between 0.7 ~ 0.9cm, mainly for the ceiling and partition. ???????? There is also a 0.6mX.6m gypsum board, also known as silicon calcium board for office and ordinary room ceiling. PVC board: a flat and profiled plate specifications vary, for the ceiling, partitions, canopy and so on.

- Q:PVC sheet and PVC coil What is the difference, what are the advantages and disadvantages?

- PVC flooring according to its shape points can be divided into two kinds of sheet flooring and coil flooring, in accordance with market sales and development trends, PVC sheet flooring sales in decline year by year trend, and PVC coil floor sales increased year by year Development trend, PVC sheet flooring increasingly popular, PVC flooring industry is the first choice, but also the current hot floor sales, according to experts predict: the next 2-3 years, PVC coil flooring sales may be doubled

- Q:Pvc crystal plate 1.6mm per square meter with multiple

- The proportion of PVC crystal plate is 1.35 g / cm3, 1.6mm weight per square meter should be 100 cm × 100 cm × 0.16 cm × 1.35 g / CM3 = 2160 g.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bright PVC Ceiling Panels With Various Colours

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords