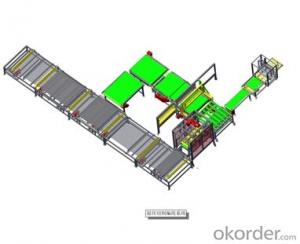

brick making machine-two stage vacuum extruder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: It is an extruding & molding equipment with strong points of reasonable distribution of grains, homogeneity of moisture content, fit for raw material with low plastic nature. It is suitable for material such as coal gangue, fly ash mixture, shale, clay, etc. It adopts hard gear reducer. Use powerful or oil lubricant, with long life span, and it can guarantee the extruding pressure. Clutch is operated by electro or pneumatic, easy to realize automatic control.

Technical Parameter:

Type | Diameter of reamer of extruding end (mm) | Capacity (pieces(standard brick size)/h) | Authorized pressure(Mpa) | Vacuum Degree(Mpa) | Installed capacity(kw) | Dimension(mm) |

JKY70/70-2.5 | 700 | 19000~24500 | 2.5 | -0.092 | 250+90+1.5 | 6687×6765×2846 |

JKY70/60-3.8 | 600 | 14000~15000 | 3.8 | -0.092 | 250+90+2.2 | 6632×6855×2866 |

JKY60/60-4.0 | 600 | 21000~24480 | 4.0 | -0.092 | 250+90+7.5+1.5 | 4819×6416×3065 |

JKY60/50-4.0 | 500 | 12000~18000 | 4.0 | -0.092 | 200+75+1.5 | 5844×6102×2796 |

JKY50/50-4.0 | 500 | 12200~13420 | 4.0 | -0.092 | 200+90+7.5+1.5 | 6904×5352×2820 |

JKB50/45-3.0 | 450 | 9800~15100 | 3.0 | -0.092 | 132+55 | 5375×4521×2723 |

JKR50/45-2.0 | 450 | 12000~16000 | 2.0 | -0.092 | 110+55 | 4900×4204×2723 |

- Q:What are the brick-making materials?

- but also through the replacement of mold, the production of different types of road brick, It is suitable for road, highway, square, road laying, improve the urban ecological environment, beautify the urban environment, protect the soil and water from being lost.

- Q:Where is the brick of the tiles used to make the brick better?

- can absorb moisture and heat, adjust the surface of the local space temperature and humidity, the regulation of urban microclimate, ease the effect of urban heat island has a greater role 3, can reduce the city drainage and flood control pressure, to prevent public waters pollution and sewage treatment

- Q:What kind of configuration does the small semi-automatic cement brick machine include?

- (Including the color material system) 11, the host (not including the color material system) 12, the green conveyor 13, the stacking machine 14, the board 15, the central electrical control room 16, the raw material yard,

- Q:Cement brick machine brick machine advantages

- Cement hollow brick machine is the production of brick-free brick brick machine, is the production of brick can not be used.

- Q:Fly ash Mianshao brick machine is not a kind of construction waste with coal ash to do brick, who understand this thing?

- Mainly used to suppress the fly ash, sand, sand, sand, slag, slag as the main raw material of Mianshaozhuan, steamed sand bricks, refractory bricks and hollow brick production, is the country strongly advocated environmentally friendly Building materials equipment.

- Q:How does the economical brick machine use the building waste brick?

- The waste of construction waste will be processed into a raw material of building materials, that is, recycled aggregate,

- Q:Installation and commissioning of hydraulic press

- 1, check the brick machine in the transport process is damaged or deformation (especially pay attention to hydraulic pipe).

- Q:How can a free brick brick brick machine be classified?

- According to the empty form: divided into square hole block and round hole block.

- Q:Free burning brick brick brick machine can be how to classify

- According to aggregate: divided into ordinary concrete small hollow block, light aggregate small hollow block

- Q:Brief introduction of cement brick machine

- Can be said to invest less, quick, is a lot of investors to invest in the popular industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

brick making machine-two stage vacuum extruder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords