Breathable Membrane for Roofing Construction with UV

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Breathable Membrane for Roofing Construction with UV

Introduction:

Breathable Membrane is a water resistant membrane but with high vapor permeability, use as diffusion open roofing felts under pitched roof tile or vapor permeable barrier house wraps on timber frame walls.

Breather membrane functions as a weather-resistant barrier, preventing rain from getting into the roof or wall assembly while allowing water vapor to pass to the exterior.

Breather membrane may also serve as an air barrier if it is sealed carefully at seams.

Breathable Membrane have good "water resistance", good "water vapor permeability", and good "air barrier properties". Weather Proof House Wrap.

Specification:

Surface mass density | 80 g/m² | ||

Roll size | 1.5m*50m or customized | ||

Vapor permeability | ≥2250 g/m²/24h | ||

Sd value | 0.02 m (-0.005/+0.015) | ||

Water tightness | class W1 | ||

Tensile strength MD/CD | 105/70N/50 mm (+/-20%) | ||

Tearing strength MD/CD | 50/60 N (+/-20%) | ||

Resistance to UV rays | 3 months | ||

Reaction to fire | Class F | ||

Loading quantity | 20’GP | 40’GP | 40’HC |

By bulk (1.5*50) | 1140rolls | 2450rolls | 2700rolls |

With pallets (1.5*50m) | 900rolls | 1954rolls | 2122rolls |

Jumbo rolls (1.5*3500m) | 14rolls | 30rolls | |

Advantages:

1)Excellent performance at water resistance

2)Particular function of water vapor permeability

3)Good performance at UV resistant for 3 months

4)They are much lighter than bitumen felts, suitable for construction in different condition

5)They have excellent tensile and tearing strength

6)100% recyclable

7)Simple installation in new building, re-roofing and refurbishment situations

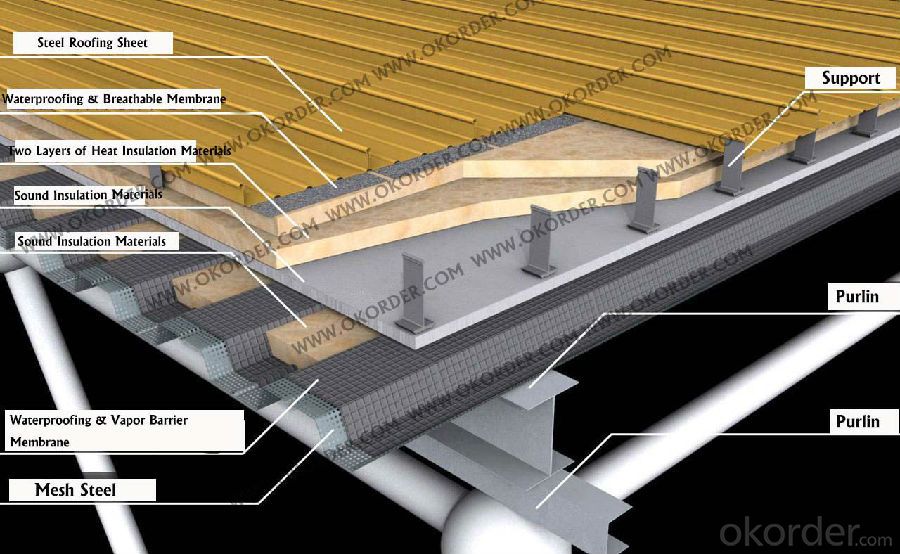

Typical Installation:

Typical Application:

Prodution Packages & Container Loading

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q:How do you make waterproofing in the kitchen and bathroom?

- Kitchen and toilet is a relatively stable part of the home improvement structure, it is recommended to do waterproof mortar waterproofing agent on it, mortar waterproofing agent not only with the base surface bonding firm, and puncture resistance, high strength, waterproof life and construction Material with the life, the construction of relatively waterproof coating is also relatively simple.

- Q:Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Third, from the indoor water leakage area for waterproof maintenance.

- Q:Eastern rainbow waterproof how to do

- especially small places to pay attention, such as: sewer such as. And then dry about 10 hours or more, (see the environment may be, like a dry) so repeated 3 side painting is appropriate.

- Q:Find the construction steps for waterproof coatings

- 2, waterproof layer construction sequence and methods (1) base surface treatment and acceptance of qualified, and now Yin, Yang angle and construction joints and other special parts brushing waterproof coating layer, strengthen the layer 1 mm, strengthen the layer after brushing, immediately paste fiberglass cloth or 30 ~ 40g / ㎡ polyester cloth reinforcement layer, is strictly prohibited to strengthen the surface layer and then paste the reinforcement layer material. (2) to strengthen the layer of hard work, began to brush a large waterproof layer, waterproof layer using multi-channel (3 to 5) brushing, brushing the upper and lower coating should be perpendicular to each other. When the surface of the coating is completely cured (not sticky hands) before the next curtain coating construction. (3) polyurethane coating waterproofing layer after the completion of the experience of acceptance, the timely application of the waterproof layer of the protective layer, the plane protective layer with 7 cm thick fine stone ㎝, in the pouring of fine stone before the need to cover the waterproof layer A layer of 350 # paper tire linoleum insulation layer. Facade waterproof layer (such as anti-beam facade) with a thick 6 mm polyethylene foam protection (expansion ratio of not more than 25 times).

- Q:Nanning building waterproof material market where

- to buy what materials are going to go to some factories, such as paper, printing materials and other manufacturers in the Nanning High-tech Zone or Nanning Economic Development Zone may be more

- Q:Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q:Cabinet is to buy finished products, or directly to the decoration company to do?

- Do the cabinet can be in accordance with your size, finished cabinet moldy, which is not necessarily. You have to buy some of the Well

- Q:There is no formaldehyde in the finished putty

- In addition, the addition of redispersible latex powder in the putty powder will make the putty have stronger adhesion and mechanical properties, outstanding water resistance, permeability, as well as excellent alkali resistance, abrasion resistance, and can improve water retention Sex, increase the opening time, enhance the durability.

- Q:Oriental rain rain waterproof how to

- Oriental rain rain waterproof paint is not good to say it, but real to do it, rely on the quality of their own business for the relentless pursuit and practice. Oriental rain rain waterproof coating from the selection to the production to the final product testing are as much as possible meticulous.

- Q:Roof sunscreen waterproof layer leakage, brush milk white plastic can solve it?

- Can not If the roof of a large area of ??leakage or a number of water leakage points, the first professional staff to check whether the cracks, the first to deal with leakage cracks in the roof covered with waterproof membrane, to enhance the waterproof effect, you can also shop On the insulation board, because the height of the insulation board in 20 cm or more, to achieve the protection of waterproof layer and thermal insulation of the double effect. Do not use the roof of the insulation board, you can consider the use of steel mesh mixed soil. Wall cracks caused by cracks in the water, under normal circumstances the professional construction team will use the basket, by the maintenance staff in the external wall construction. Large cracks can be used to plug the king, a small crack can be used to seal the glass glue, repair with a wall waterproofing agent, after spraying a few words on it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Breathable Membrane for Roofing Construction with UV

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches