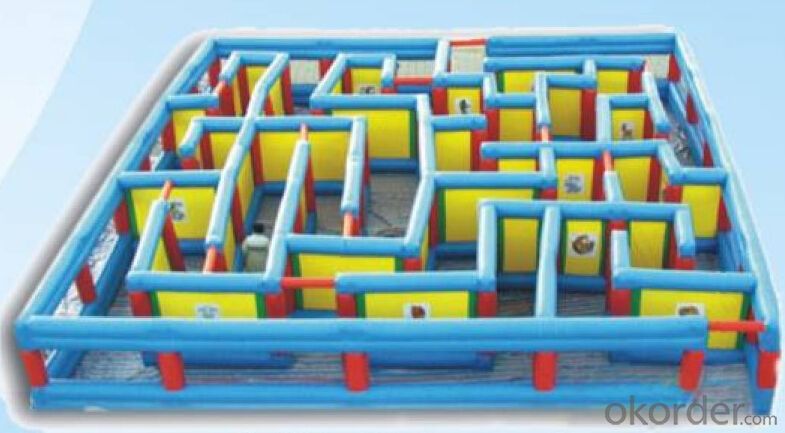

Bounce House & Inflatable games & Inflatable Castles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

0.55mm PVC tarpaulin,thickness heavy-duty, laminated and coated pvc fabric. Our materials are puncture-proof, fire-resistant and comply with SGS& ASTM (American Society for Testing and Materials) toy safety standards.

Specification:

size:other customized sizes available

colors:As customized

produce Time:7-15 working days after deposit of payment received

shipping way:By sea /by air/by DHL

weight:Accordingly

warranty:2 years

blower:CE/UL and free of charge

certificate:EN71/SGS/CE/UL/Lead free/ EN14960

printing:Logo/ Banner/web site /phone/company name and so on all availabe

OEM AND ODM:ACCEPTED

Quality control:

1. Double stitching throughout the unit with triple stitching

2. Quadruple stitching in key areas inside the base. Extra webbing reinforced strip on all the stress points and interior panels

Come with:1. 2 years warranty 2. FREE blower(if customer want to buy the blower) 3. repair kits 4.Safe rule 5.Banner with your phone No/company name

FAQ:

1. Production: We will make special arrangements for your urgent orders to meet your time if needed.

2. Durability: All our inflatables are with the toughest and most durable materials.

- Q:How does an olive net affect the overall fruit color in the olive grove?

- An olive net can significantly impact the overall fruit color in an olive grove. By covering the trees, it prevents direct sunlight from reaching the olives, which can delay the ripening process. This delay in ripening often results in a lighter or less intense color of the fruit. Additionally, the netting can create shade and reduce the temperature around the olives, further affecting their color development.

- Q:What materials do you use for plastic moulds?

- As there are many varieties of plastics, the requirements for plastic products vary greatly, and various materials for making plastic moulds are also put forward

- Q:Are olive nets adjustable for different tree heights?

- Yes, olive nets are often adjustable for different tree heights. They typically come with adjustable straps or ropes that can be tightened or loosened to fit the specific height and size of the olive tree.

- Q:Can olive nets be used for both small and large-scale olive oil production?

- Yes, olive nets can be used for both small and large-scale olive oil production. Olive nets are commonly used to collect olives during the harvesting process, regardless of the scale of production. They help prevent olives from falling onto the ground, ensuring a higher yield and quality of olives for oil extraction. Whether it is a small family-owned olive grove or a large commercial plantation, the use of olive nets is an effective and practical method for olive oil production.

- Q:Can olive nets be used for both outdoor and greenhouse olive cultivation?

- Yes, olive nets can be used for both outdoor and greenhouse olive cultivation. Olive nets are versatile and can protect olive trees from pests and birds, as well as provide shade and reduce evaporation in outdoor settings. In greenhouses, olive nets can help regulate temperature and humidity, while also preventing birds and pests from damaging the olive trees.

- Q:Can olive nets withstand harsh weather conditions?

- Yes, olive nets are designed to withstand harsh weather conditions. They are made from durable and weather-resistant materials that can withstand strong winds, heavy rainfall, and intense sunlight. These nets provide protection to olive trees and harvests, ensuring that they can withstand adverse weather conditions without getting damaged.

- Q:Can olive nets be used in olive tree nurseries?

- Yes, olive nets can be used in olive tree nurseries. These nets are commonly used to protect the trees from extreme weather conditions, pests, and birds, ensuring proper growth and development of the olive trees in nurseries.

- Q:Can olive nets be used on trees with a thin trunk?

- Yes, olive nets can be used on trees with a thin trunk as long as the net is securely fastened to prevent any damage to the tree and to ensure effective protection against birds or other pests.

- Q:Can olive nets be used for olive trees in drought-prone regions?

- Yes, olive nets can be used for olive trees in drought-prone regions. These nets are designed to provide shade and protection to the trees, reducing water evaporation from the soil and conserving moisture. Additionally, the nets can help prevent excessive heat stress on the olive trees, promoting better growth and survival in dry conditions.

- Q:Can olive nets be used in areas with high humidity?

- Yes, olive nets can still be used in areas with high humidity. However, it is important to note that excessive moisture might affect the net's durability and performance over time. Regular maintenance, proper drying, and storage practices can help mitigate any negative effects of high humidity on olive nets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bounce House & Inflatable games & Inflatable Castles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords