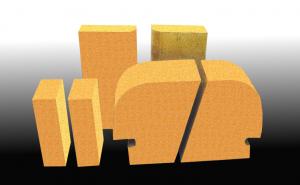

Bottom Bricks for JFE Chinba Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hereinafter referred to as a brick.Has a certain shape and size of refractory materials.

Refractory brick

According to the preparation method to classification can be divided into the burnt brick, air brick, fused brick (fused cast brick),

refractory insulating brick;According to the shape and size can be divided into standard brick, ordinary brick, and other abnormal transfer.

Can be used as a building kiln and various thermal technology equipment of high temperature materials,

building materials and structure and can withstand various physical and chemical changes in the heat and mechanical action.

Such as refractory clay bricks, high alumina brick, silica brick, magnesite brick, etc.

- Q:What kind of refractory material will be used in the glass kiln?

- 1. compact chromium oxide brickIt has the best resistance to high temperature E glass corrosion, its erosion basically does not cause pollution to the glass liquid, so it has become the first choice of E glass unit refractory bricks.Dense chromium oxide is formed by isostatic pressing. Its density is very high. The main technical indexes include Cr2O3 content >94%, porosity <15%, volume density >4.24g/cm3, and erosion loss only 1/10 of compact zirconia brick. Used in the E glass furnace unit kiln, directly contact high temperature molten glass melt, wall, melting parts, high temperature parts, pool bottom, main channel, pool wall and pool bottom, transition channel, pool wall, etc..

- Q:What refractory materials are adopted in each part of the blast furnace?

- The blast furnace throat from top to bottom, stack, belly and Bosh, hearth and bottom etc.

- Q:Is it good for your cupola to use that kind of refractory, high aluminum brick, clay brick or red silica?

- I suggest you go back to learn Chinese at primary school, and then ask questions again.Don't consider the cost, andalusite sillimanite brick well. But I don't have a cupola. It's too expensive to buy.

- Q:I am a student of refractory materials. I would like to know the general rank of national refractory materials company

- Zhejiang Sunon Refractories Co., Ltd. is a group member of the factory of industrial economy research China (country), building materials building materials industry center Changxin Branch Center of refractories. The main products are: wear-resistant refractory brick, aluminum silicate fiber board, ordinary magnesia, heavy casting materials, spalling brick kilns, special casting materials, high strength and abrasion resistant castable refractory castable, special pulverized coal burner, MF-170 coating (with fabric), clay brick, corundum wear-resistant plastic, calcium silicate board, lightweight castable and the direct combination of magnesia chrome brick, unburned magnesia chrome brick, anti flaking high alumina brick, mullite brick, antiskinning castable,

- Q:Sillimanite brick

- After calcination at high temperature, sillimanite transforms to mullite and free silica. Generally use the firing process and production of high temperature mud casting method. Its physical and chemical properties are better than those of aluminum bricks, the refractoriness is 1770~1830 degrees, and the load softening point is 1500~1650 degrees centigrade. The utility model is mainly used for the forming of a liquid hole in a glass furnace, a lining of a blast furnace, a furnace throat and a ceramic industrial kiln tool.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bottom Bricks for JFE Chinba Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords