BOPP Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 2000 Tons Per Month kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

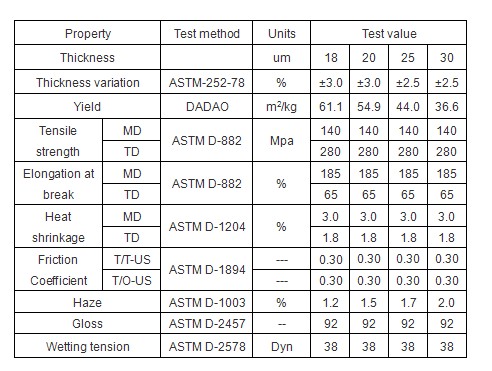

1. Specifications of BOPP Film:

2. Usage of BOPP Film:

BOPP Filmsare used for packaging for all kinds of things like cometics, clothes, industry products etc.

3. Packaging & Delivery of BOPP:

One 20GP container can be loaded about 10-15tons.

By sea or by air all available.

- Q:What to do if the plastic protective film can't be torn down?

- Stick it down using strong adhesive tape.

- Q:How to get rid of the aging protective film on stainless steel?

- Apply some rosin water at first. And then wipe it off with toilet paper or dry cloth.

- Q:How to remove the protective films on ceramic tiles?

- There are three types of protective film used on ceramic tiles: The first one is plastic thin film which can be slowly torn by hands or gently rubbed off with steel wool; The second is anti-fouling protective film which can be wipe off using towel with white cement; The third is wax protective film which can be wipe off with dry towel with electric diluent, lacquer thinner, talcum powder or white cement.

- Q:What does thickness C of the base material of protective film stand for?

- It's just a terminology about thickness in industry. 5 c = 50 um = 0.05 mm.

- Q:What is the viscous unit of a protective membrane? What is its physical meaning?

- 1g/cm=1g/10mm=2.5g/25mmSo 1g/25mm=1g/2.5cm=0.4g/cmPulling tension of 25mm wide spline is 1N

- Q:What is the privacy protective film? ? And how can it keep peepers away?

- What kind of privacy protective film are you talking about? Is it used on computer screen or car windows? However, no matter which kind it is, the principle should be the same. It's the use of polarization technology. The screen is viewable only from the front side and within the space that is 45 degrees to the front side. In this way, the content on the screen can only be seen clearly from the font side. But people who look at the screen from an angel of 30 degrees from two sides cannot see what's on the screen.

- Q:What are the main components of PE protective film?

- Polyethylene film is the main component.

- Q:What is PVC protective film?

- 1. It has the property of highlight and high reflective which is commonly called the mirror effect. 2. It has resistance to acids and alkali as well as corrosion. And no residual glue remains when removing the film. Use: It can be widely used on the protection of stainless steel sheets as well as aluminium products and industrial products during processing. The scotch tapes hanging on the doors of many restaurants are also made from PVC materials which are generally called PVC films. We have many nice films of this type . And we assure you they are all of good quality and reasonable price.

- Q:How about the electrostatic adsorptive function of PE protective film ?

- 1. Corona treatment is used in the process of the making of PE protective film, increasing the surface area of the film and making it static to meet the need of the following gluing. It's conducive to the combination of glue and film this way. 2. There's no such PE anti-static protective film with glue itself has adsorption function. Multi-layer film blowing machine can make such product at one time. Hualibao PE protective film features softness, good viscosity and easiness to stick and remove. And no glue remains after it's torn down.

Specializing in the production of PVC calender super transparent film, PVC printed film, laser laser aluminized film, PVC film, PVC ultra-thin extinction printing new environmental protection plate, PVC film, PVC transparent sheet, white films, antistatic films, plates, etc. Series of packaging materials.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang,China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 800 Million |

| Main Markets | Mid East, Northern Europe, Eastern Asia, Eastern Europe, Southeast Asia, Western Europe, Southern Europe |

| Company Certifications | ISO 9001; ISO 14001; OHSMS18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Wenzhou, Hangzhou |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 11-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 20 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

BOPP Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 2000 Tons Per Month kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords