BMT Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

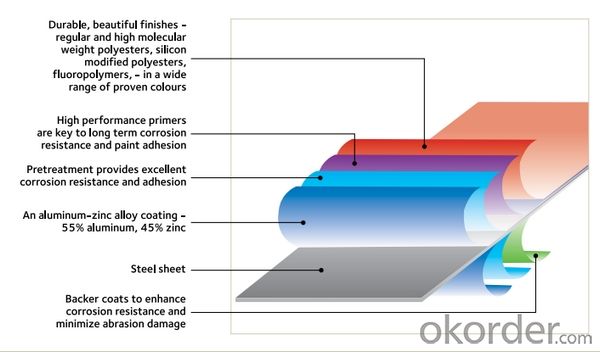

Structure of BMT Rolled Prepainted Steel Coil for Construction

Description of BMT Rolled Prepainted Steel Coil for Construction

BMT Prepainted Rolled Steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Zn coating on both faces by hot dip process. Its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of BMT Rolled Prepainted Steel Coil for Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

3. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of BMT Rolled Prepainted Steel Coil for Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel

2. Electric appliance: refrigerator; washing machine; refrigerator..

3. Transportation: oil tank; road sign; etc.

4. Agriculture:barn; etc.

5. Others: vending machine; game machine; etc.

Specifications of BMT Rolled Prepainted Steel Coil for Construction

Product | BMT Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.3-3.5mm |

Width | 600-1250mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z35-150g/m2 |

Technique | Raw material: Hot rolled steel coil > Cold rolled>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of BMT Rolled Prepainted Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is your MOQ ?

Our MOQ is 50mt. And there is more discount if you order like 1000 tons and more. The more appropriate payment term your can offer, the better price we can provide.

2. What is the general delivery time?

Usually it is within thirty working days after received buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 20- 25 days, but the shipment will depend on the vessel situation.

3. How do you promise the quality of the steels?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What different between PE and PVDF?

PVDF is the most advanced painting in construction industry, it is with high corrosion resistance and color retention, and the life time could last to 20-25 years. Currently, PE is the most widely-used painting in the color coated steel coils. It is characterized by good overall performance, and high economic as well

- Q:What are the different types of coatings applied to steel coils?

- There are multiple types of coatings that can be applied to steel coils, including galvanized coatings, which involve applying a layer of zinc to prevent corrosion; organic coatings, such as paints or lacquers, which provide protection and enhance aesthetics; and metallic coatings, like aluminum or tin, which offer corrosion resistance and improved appearance.

- Q:We have to do a project for school on steel mines and i need 4 PROPERTIES OF A STEEL MINE PLEASE HELP!!! URGENT!!!

- There's no such thing as a Steel mine - steel is made from various raw materials (and now recycled metals). These materials may be mined separately and then combined at a steel mill - but steel is made, not mined. Steel, depending on what final characteristics they're trying to develop (strength, hardness, finish , etc.) can be comprised of iron, carbon, manganese, phosphorus, sulfur, nickel, chromium, etc. in varying quantities.

- Q:What minerals are mixed to make steel?

- W - weldable steel WT- Weldable Noctch-tough steel R - Atomospheric corrosion-resistant steel A - Atomospheric corrosion-resistant steel weldable steel R - Atomospheric corrosion-resistant steel weldable Notch-tough steel Q- Quenched and tempered Low-alloy Steel QT-Quenched and tempered Low-alloy Steel Notch-tough steel For W and WT: C, Mn, P, S, Si, small quanties Cb,V,Al For R, A, AT: C, Mn, P, S, Si, Cr, Ni, Cu small quanties Cb,V,Al For Q: C, Mn, P, S, Si, Cr, Ni, Cu, and small amounts of boron See CSA G40.21 if you want more info

- Q:I'm going to buy a guitar for beginners and i wondered what strings are better steel or nylon?

- I urge you to read the answer from OU again and ignore the others - who obviously haven't got the first clue of what they're talking about. You pick the guitar for the type of music (and sound) you're after. You can play basically everything on a steel string that you can on a nylon string, plus a whole lot more... And no, a classical guitar is NOT easier to play than a well adjusted steel string with light strings - in fact it's the opposite. A classical guitar has a wide, flat fingerboard, something which makes chords much harder to play. Furhermore, the scale is longer (the scale is the distance between the nut and bridge - the length of the vibrating string if you will). This longer scale increase the distance between the fret (increasing the reach), and also increase the string tension. Finally, the action (string height) is larger on a classical/nylon string guitar as opposed to a steel string guitar which has been properly adjusted. Most guitars off the shelf have an inferior set up for a beginner, and this is why many have this funny idea that a steel string is much harder to play. You may also want to check out guitar body sizes (steel string) that is smaller than the large Jumbo or Dreadnought varieties. In essence, if you play classical music, or classical finger style guitar - choose a nylon string instrument. If not, then get a steel string and have it properly adjusted. Make sure you try out a lot of models as the necks, bodies, woods etc, differ a lot.

- Q:What are the environmental and social impacts of mining, processing and using steel?

- Without it, you would not have many of the things that you enjoy today. Just think, no cannons, unless they were made of bronze, but that requires mining as well. No computers, no cars, no skate boards, no tall buildings, no pots and pans, no bath tubs, no factories to build things that are made out of non-metallic materials. No stereos, no TVs, no eating utensils, just think, you would have to eat like the Japanese do with bowls and your fingers. In short, just about everything around you is some how made with steel. If you are against steel and feel that it's impact on the ecology of the world is to great, what would you be willing to give up? Your car, ipod, computer, stereo, bed-everything about it uses steel in 0one way or another. Your Cd's, DVDs, just what would you want to give up because, yuck, it was made with steel equipment, or to some extent, made from steel.

- Q:What are the challenges in coil blanking for high-strength steel?

- Some challenges in coil blanking for high-strength steel include the increased hardness and strength of the material, which can lead to greater wear and tear on cutting tools. Additionally, high-strength steel may have less ductility, making it more prone to cracking or breaking during the blanking process. The higher tensile strength and spring-back characteristics of the steel also require precise control and adjustment of blanking parameters to ensure accurate and consistent part dimensions.

- Q:What are the common methods of protecting steel coils from corrosion during storage?

- To safeguard steel coils from corrosion during storage, there are multiple commonly employed techniques. These methods aim to shield the steel coils from moisture and other environmental factors that could trigger corrosion. 1. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging is extensively utilized for steel coil protection. It incorporates VCI materials into the packaging, such as plastic bags or films. These materials emit a vapor that forms a protective layer on the surface of the steel coils, effectively preventing the intrusion of moisture and corrosive agents. 2. Oil Coating: Another widely adopted approach involves applying a thin layer of oil onto the steel coil surface. This oil acts as a barrier, obstructing the contact between the steel and moisture or oxygen. It proves particularly effective for long-term storage or transportation situations. 3. Desiccants: Silica gel packets or similar desiccants can be placed inside the packaging to absorb any trapped moisture. By reducing humidity levels within the packaging, the risk of corrosion is minimized. This method is often combined with VCI packaging or oil coating. 4. Proper Ventilation: Adequate ventilation is crucial to prevent moisture buildup around the steel coils during storage. By facilitating the free circulation of air, humidity levels are reduced, and the formation of condensation, which can lead to corrosion, is prevented. 5. Controlled Environment: Storing steel coils in a controlled environment is an effective corrosion prevention measure. This entails maintaining constant temperature and humidity levels that are unfavorable for corrosion. Temperature and humidity control can be achieved using air conditioning or dehumidification systems. It should be noted that the choice of specific protection methods or combinations thereof depends on various factors, including storage duration, environmental conditions, and specific steel coil requirements. Regular inspections and maintenance are also vital to ensure ongoing corrosion protection.

- Q:What are the challenges faced during steel coil processing?

- Some of the challenges faced during steel coil processing include ensuring proper alignment and feeding of the coils into the machinery, handling the heavy weight and size of the coils, managing the high temperatures involved in processing, preventing surface defects or damage to the steel, maintaining consistent quality throughout the process, and minimizing material waste and scrap.

- Q:Can steel coils be coated with decorative designs?

- Yes, steel coils can be coated with decorative designs. This process is known as coil coating, where a decorative or protective coating is applied to the surface of the steel coils to enhance their appearance or provide additional functionality.

- Q:What are the main factors that affect the corrosion resistance of steel coils?

- The main factors that affect the corrosion resistance of steel coils include the composition of the steel, the presence of impurities, the type and thickness of the protective coating, exposure to corrosive environments (such as moisture, chemicals, and salt), and the presence of physical damage or scratches on the surface of the coils.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BMT Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords