BMP Z15 PPGI Rolled Steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

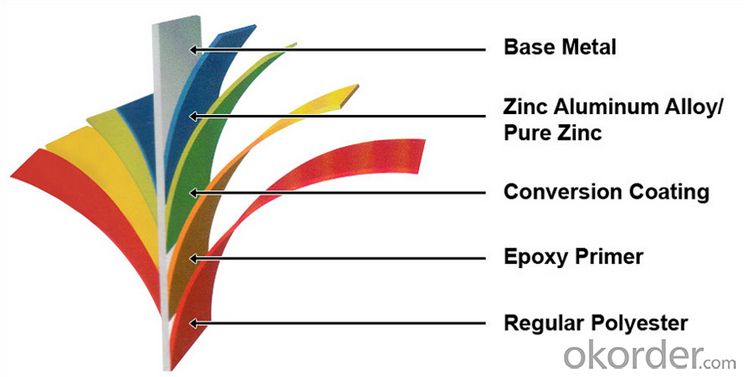

Structure of BMP Z15 PPGI Rolled Steel Coil for Construction Roofing Constrution

Description of BMP Z15 PPGI Rolled Steel Coil for Construction Roofing Constrution

Galvanized sheet or coil is defined as a carbon steel sheet coated with zinc on both sides. Continuous hot dipping, or electro-galvanizing are the two processes used to produce galvanized sheet and coil. Generally speaking, the hot dip process consists of passing the steel through a bath of molten zinc. The electro galvanizing process consists of the application of zinc by electrolytic disposition.The result is a layer of zinc tightly adhering to the base metal through an iron-zinc bonding layer.

Main Feature of BMP Z15 PPGI Rolled Steel Coil for Construction Roofing Constrution

1. Resistance to Corrosion Has better performance in corrosion resistance than hot dip galvanized coil/sheet of the same thickness and its service life is 1-5 times longer than general hot dip galvanized coil/sheet.

2. Machinability Can satisfy the processing requirements of rolling, coiling and others processes alike.

3. Thermal Resistance Can sustain the environment at 315Centigrade for long time.

4. High Reflectivity Reflection ability of heat and light is twice as much as those of hot dip galvanized steel coil/sheet, and its reflectivity is more than 0.75, exceeding 0.65 (required by the EPA Energy Star Standard), which is an ideal construction material of saving energy.

Applications of BMP Z35 PPGI Rolled Steel Coil for Construction Roofing Constrution

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Specifications of BMP Z15 PPGI Rolled Steel Coil for Construction Roofing Constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP BMP Z15 PPGI Rolled Steel Coil for Construction Roofing Constrution

We have organized several common questions for our clients,may help you sincerely:

1.Are you a factory or a trading company?

CNBM is a trading company in this industry over 30 years, located in Beijing

2.Are the products tested before shipping??

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q:Is cold steel actually steel? Does it hurt? Why is it used in training? First one to goodly answer those questions gets 10 points.

- Cold steel was an expression originally used to signify a sword. From feeling the cold of the blade as it entered the body.

- Q:I have a 03 jeep wrangler and looking to upgrade to black wheels. I was wondering if the difference between steel and alloy wheels is worth paying double.

- steel is steel is steel- they will always be heavy you would have to weigh them to find out--NOW if you are going to alloy wheels they are typically aluminum and yes they are lighter -this is good because it lightens your un-sprung weight and is less harmful to your suspension-good for your auto

- Q:What is the thickness of a steel coil?

- The thickness of a steel coil can vary depending on the specific application and requirements. However, it typically ranges from a few millimeters to several centimeters.

- Q:What are the different methods of coil welding for steel coils?

- There are several different methods of coil welding for steel coils, each with its own advantages and disadvantages. Here are some of the most commonly used methods: 1. Resistance Welding: This method involves passing an electric current through the coils to generate heat, which then fuses the two ends together. Resistance welding is a fast and efficient process that produces strong and reliable welds. It is commonly used in industries where high-speed production is required. 2. Arc Welding: Arc welding uses an electric arc between an electrode and the workpiece to create a weld. This method can be further divided into different processes, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). Arc welding provides good penetration and can be used on a wide range of steel coils. 3. Laser Welding: Laser welding utilizes a high-powered laser beam to melt and fuse the two ends of the coils together. This method offers precise control, high welding speeds, and minimal distortion. It is often used in applications where precision and aesthetics are crucial, such as the automotive and electronics industries. 4. Induction Welding: Induction welding involves heating the coils using electromagnetic induction. The heat generated melts the edges, which are then pressed together to form a weld. This method is particularly suitable for thin-gauge steel coils and provides good control over the welding process. 5. High-Frequency Welding: High-frequency welding utilizes high-frequency current to heat and weld the coils together. This method is commonly used for pipes and tubes and offers high production rates and good weld quality. 6. Friction Welding: Friction welding uses the heat generated by rubbing the two ends of the coils together to create a weld. This method is fast, reliable, and produces strong joints. It is often used in applications where high-strength welds are required, such as the automotive and aerospace industries. These are just a few of the different methods of coil welding for steel coils. The choice of method depends on factors such as the type and thickness of the steel, the required weld strength, production speed, and overall project requirements.

- Q:What are the dimensions of steel coils used in the metal furniture industry?

- The dimensions of steel coils used in the metal furniture industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry range from 0.5mm to 3mm in thickness and 600mm to 2000mm in width.

- Q:How do steel coils perform in high-temperature applications?

- Steel coils perform well in high-temperature applications due to their excellent heat resistance and structural stability. The high melting point of steel allows it to maintain its strength and shape even at elevated temperatures, making it suitable for various industries such as automotive, construction, and manufacturing. Additionally, steel coils can withstand thermal expansion and contraction without warping or deforming, ensuring reliable performance and durability in extreme heat conditions.

- Q:How are steel coils secured during transportation?

- Steel coils are typically secured during transportation using steel strapping, banding, or wire rope. These materials are tightly wrapped around the coils and fastened to prevent any movement or shifting during transit. Additionally, wooden or steel blocking may be used to further secure the coils and prevent them from rolling.

- Q:I need to know how you rate the hardness of steel any ideas?

- For the backyarder to rate hardness, you do a file test. If a smooth file will not mark the steel, it's around 60+RC (Rockwell C scale). If it will mark it with difficulty, the hardness is probably around 56- 58RC. If it will file easily, it's mild steel or is in annealed form, if it is a hardenable steel.

- Q:Can steel coils be coated with thermally insulating materials?

- Yes, steel coils can be coated with thermally insulating materials. These materials help to reduce heat transfer and provide insulation to the steel coils, enhancing their thermal resistance.

- Q:How are steel coils used in the production of roofing panels?

- To manufacture roofing panels, steel coils are indispensable. These coils, usually composed of galvanized or coated steel, serve as the fundamental material for producing robust and top-notch roofing panels. Initially, the steel coils undergo a sequence of operations in a production facility. These operations involve flattening, cleaning, and shaping the coils to achieve the desired dimensions and profiles for the roofing panels. This process guarantees that the steel coils possess uniform thickness and are devoid of any impurities or flaws that could compromise the final product's integrity. Once the steel coils are prepared, they are fed into a roll forming machine. In this machine, the coils are gradually bent and shaped into the specific design and size required for the roofing panels. The roll forming process imparts the panels with their distinct corrugated or standing seam profiles, which enhance their strength and ability to withstand various weather conditions. After the roll forming process, the steel coils are divided into individual roofing panels of the desired length. These panels then undergo further processing to incorporate additional features, such as coatings or finishes, to enhance protection against corrosion and improve aesthetic appeal. Protective layers, such as zinc or paint, are often applied to the steel coils to enhance their resistance to rust, UV rays, and other environmental factors. Lastly, the roofing panels are packaged and transported to construction sites or distributors for installation. The utilization of steel coils in the production of roofing panels ensures that the final product is sturdy, long-lasting, and capable of withstanding heavy loads, strong winds, and other external forces. Steel is renowned for its high tensile strength, making it an ideal material for creating durable roofing panels. In conclusion, steel coils play a vital role in the production of roofing panels. Through a series of manufacturing processes, they are transformed into the desired dimensions and profiles, ensuring consistency and quality. The resulting roofing panels are not only visually pleasing but also highly resilient, providing superior protection and longevity for buildings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BMP Z15 PPGI Rolled Steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords