Blast Furnace 5SP CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description of Blast Furnace 5SP CNBM Steel Billets with High Quality

| GRADE | SIZE | APPLICATION |

| 5SP | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Blast Furnace 5SP CNBM Steel Billets with High Quality

| 5SP | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.28-0.37 | 0.15-0.30 | 0.50-0.80 | 0.040% Max | 0.05Max |

Company Information of Blast Furnace 5SP CNBM Steel Billets with High Quality:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Packing & Delivery for Blast Furnace 5SP CNBM Steel Billets with High Quality

1. Packaging: seaworthy package or as required

2. Delivery: 35-45 days or based on quantity

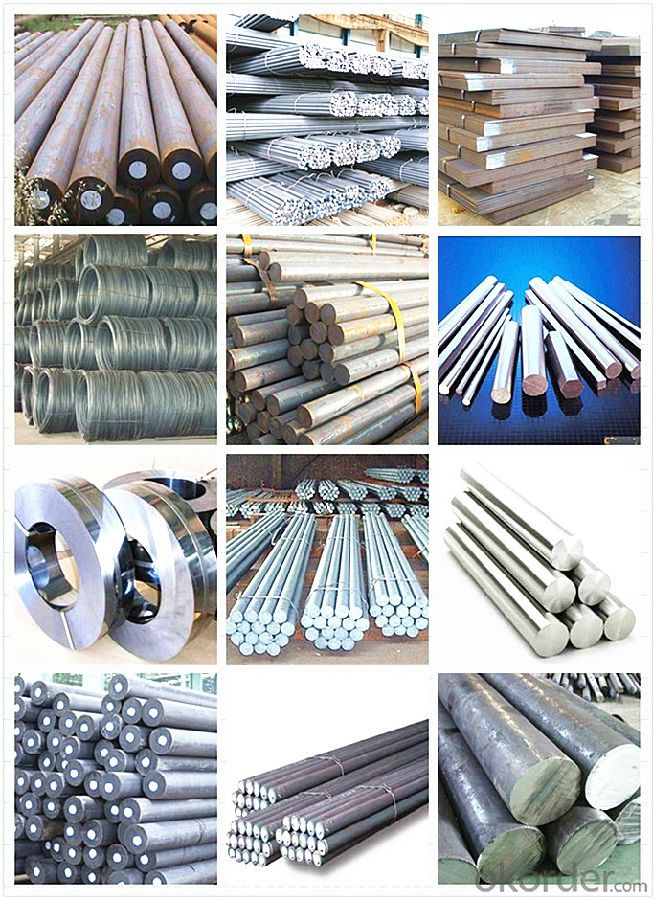

Products Show

Workshop

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:How is electrical steel used in the production of transformers and motors?

- Electrical steel is commonly used in the production of transformers and motors due to its unique magnetic properties. It is used to construct the cores of transformers and the stators and rotors of motors. The high magnetic permeability and low electrical resistance of electrical steel help in efficiently transferring and converting electrical energy. Additionally, its low core losses and hysteresis make it ideal for reducing energy wastage and enhancing the overall performance of these electrical devices.

- Q:What are the different forms in which special steel is available?

- Special steel is available in various forms such as bars, plates, sheets, tubes, wires, and forgings.

- Q:How does special steel contribute to the transportation equipment industry?

- Special steel plays a crucial role in the transportation equipment industry in several ways. Firstly, special steel alloys are used to manufacture various components of vehicles, such as engine parts, suspension systems, and transmission components. These alloys offer superior strength, durability, and corrosion resistance, ensuring that the vehicles can withstand harsh operating conditions and have a longer lifespan. Moreover, special steel is also employed in the production of railway tracks and infrastructure, contributing to the efficiency and safety of the transportation system. The high-quality steel used in railway tracks ensures stability, reduces maintenance requirements, and enhances the overall performance of the railways. In addition, special steel is utilized in the manufacturing of aircraft components, where precision, reliability, and lightness are of utmost importance. Steel alloys with exceptional mechanical properties are employed in critical parts like landing gear, engine components, and structural elements, ensuring the safety and efficiency of air transport. Furthermore, special steel is vital in the production of ships and marine vessels. The use of corrosion-resistant steel alloys in shipbuilding helps to prevent rusting, prolonging the lifespan of the vessels and reducing maintenance costs. Additionally, the high strength-to-weight ratio of certain steel alloys enables the construction of lighter ships, leading to increased fuel efficiency and reduced emissions. Overall, special steel's unique properties and characteristics make it an indispensable material in the transportation equipment industry. Its contribution to the sector includes enhancing the performance, safety, and durability of vehicles, railways, aircraft, and ships, ultimately improving the efficiency and reliability of transportation systems.

- Q:What industries commonly use special steel?

- Special steel, also known as alloy steel, is widely used in various industries due to its exceptional properties and performance characteristics. Some of the industries that commonly utilize special steel include: 1. Automotive Industry: Special steel is extensively used in the manufacturing of components for automobiles, such as crankshafts, camshafts, gears, and axles. Its high strength, durability, and excellent heat resistance make it ideal for withstanding the demanding conditions of the automotive sector. 2. Aerospace Industry: Special steel finds applications in the aerospace industry for manufacturing critical components like turbine blades, landing gear, and structural parts. Its ability to withstand high temperatures and maintain structural integrity under extreme conditions is crucial for aerospace applications. 3. Oil and Gas Industry: Special steel is vital in the oil and gas sector for applications like drill bits, valves, pipelines, and offshore platform components. Its corrosion resistance, high strength, and resistance to extreme temperatures and pressures make it suitable for these demanding environments. 4. Construction Industry: In the construction industry, special steel is used in the fabrication of structural components, reinforcement bars, and high-rise building frameworks. Its high tensile strength, toughness, and resistance to wear and tear ensure the safety and stability of the structures. 5. Tool and Die Industry: Special steel is widely used in the tool and die sector for manufacturing cutting tools, molds, dies, and various machine components. Its ability to retain sharpness, resist deformation, and withstand high pressures and temperatures make it indispensable for these applications. 6. Energy Industry: Special steel is extensively used in power generation plants, including nuclear, thermal, and renewable energy facilities. It is used for manufacturing turbines, boilers, heat exchangers, and other critical components due to its high temperature and corrosion resistance properties. 7. Medical Industry: Special steel plays a crucial role in the medical field, especially in surgical instruments and implants. Its biocompatibility, strength, and resistance to corrosion make it suitable for applications like joint replacements, dental instruments, and surgical cutting tools. 8. Manufacturing Industry: Special steel is widely used in various manufacturing processes, such as machining, forging, and casting. It is employed in the production of machine tools, industrial equipment, and heavy machinery components due to its high strength, toughness, and versatility. These are just a few examples of the industries that commonly utilize special steel. Its unique properties make it an essential material for a wide range of applications, where strength, durability, heat resistance, and corrosion resistance are critical factors.

- Q:What are the main factors affecting the corrosion fatigue strength of special steel?

- The main factors affecting the corrosion fatigue strength of special steel include the corrosive environment, the presence of aggressive substances, the level of stress applied, the frequency of stress cycling, and the microstructure and composition of the steel itself.

- Q:Can special steel be used in mining applications?

- Yes, special steel can be used in mining applications. Special steel alloys are often utilized in mining equipment and machinery due to their high strength, durability, and resistance to wear and corrosion. These properties make them suitable for withstanding the harsh and demanding conditions found in mining operations.

- Q:What are the emerging trends in special steel production?

- The special steel production industry is being shaped by several emerging trends: 1) The industry is experiencing an increasing demand for high-performance alloys. Technological advancements and industrial applications require special steels with superior properties, such as high strength, corrosion resistance, and heat resistance. This has led to a higher demand for alloys like stainless steel, tool steel, and superalloys. 2) Advanced manufacturing techniques, such as additive manufacturing (3D printing) and precision machining, are being adopted for special steel production. These techniques allow for the production of complex geometries and customized components, resulting in improved efficiency and reduced material waste. 3) Sustainability is a key focus in the steel industry. Special steel producers are adopting sustainable practices, such as using recycled materials, energy-efficient production processes, and waste management strategies. Investments in cleaner technologies are being made to meet the growing demand for sustainable steel products. 4) The integration of digital technologies, automation, and data analytics, known as Industry 4.0, is revolutionizing special steel production. Real-time monitoring, predictive maintenance, and optimization of production parameters are made possible through Industry 4.0 solutions. This leads to increased productivity, quality, and cost-effectiveness. 5) Special steel producers are developing new alloys to meet the specific requirements of emerging industries like aerospace, renewable energy, and electric vehicles. For example, lightweight, high-strength steels are being developed for aerospace applications, and corrosion-resistant steels for offshore wind turbines. 6) Collaborations and partnerships between special steel producers, research institutions, universities, and other industry players are on the rise. These collaborations drive innovation, knowledge sharing, and the development of new steel grades, applications, and production processes. In conclusion, the future of special steel production is being shaped by the demand for high-performance alloys, adoption of advanced manufacturing techniques, focus on sustainability, integration of Industry 4.0 technologies, development of alloys for emerging industries, and collaborations. These trends create opportunities for growth and innovation in the industry.

- Q:How does special steel resist deformation under load?

- Special steel resists deformation under load due to its unique properties and composition. It is typically made with higher levels of alloying elements such as chromium, nickel, and molybdenum, which enhance its strength, hardness, and toughness. These alloying elements form strong bonds within the steel's crystal lattice structure, making it more resistant to deformation. Additionally, special steels often undergo heat treatment processes such as quenching and tempering, which further refine their microstructure and increase their ability to withstand loads without deforming. Overall, the combination of alloying elements and heat treatment techniques allows special steel to maintain its shape and structural integrity even under high-stress conditions.

- Q:What are the requirements for special steel used in pharmaceutical manufacturing?

- The pharmaceutical manufacturing industry demands stringent requirements for special steel. To guarantee the safety, purity, and effectiveness of the products, the steel must adhere to specific specifications and meet various criteria. Foremost, the steel used in pharmaceutical manufacturing must be of top-notch quality and possess exceptional corrosion resistance. This is vital to prevent any contamination or reaction with the pharmaceutical compounds or chemicals involved. It is imperative that the steel does not release any impurities that could compromise the purity of the final product. Additionally, the steel must be capable of withstanding high temperatures and pressures, as pharmaceutical manufacturing processes often involve heat treatment, sterilization, and other high-temperature operations. It is crucial that the steel maintains its structural integrity and does not affect the quality of the pharmaceutical products under these conditions. Another significant requirement for the steel used in pharmaceutical manufacturing is easy cleanability. The steel should have a smooth surface without any cracks, crevices, or rough areas that could trap bacteria, contaminants, or residues. This is essential to maintain the hygiene and sterility of the manufacturing environment and ensure that the pharmaceutical products meet the highest quality standards. Furthermore, the steel must comply with regulatory standards and industry guidelines. It should meet the specific requirements set by regulatory bodies such as the Food and Drug Administration (FDA) or the European Medicines Agency (EMA). These standards often include specifications regarding the composition, mechanical properties, and traceability of the steel. In conclusion, the requirements for special steel used in pharmaceutical manufacturing are strict and encompass factors such as top-notch quality, corrosion resistance, heat resistance, cleanability, and compliance with regulatory standards. Meeting these requirements is vital to guarantee the safety, purity, and effectiveness of the pharmaceutical products manufactured using this steel.

- Q:What are the different heat treatment processes used in special steel production?

- Some of the different heat treatment processes used in special steel production include annealing, tempering, quenching, normalizing, and hardening.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Blast Furnace 5SP CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords