Black Silicon Carbide for Abrasives and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | silicon carbide | Model Number: | silicon carbideF4-f240 |

| Material: | silicon carbide | Usage: | abrasive for grinding ball,refractory material, | Abrasive Grain Sizes: | F4-F240 |

| silicon carbide: | black |

Packaging & Delivery

| Packaging Details: | 25 kg bags on pallet up to 1 ton 1 ton loose in big bag |

| Delivery Detail: | 15days |

Product Description

Products Picture

Black silicon carbide consists of crystalline silicon carbide, which is produced from silica sand and petroleum coke in electric resistance furnaces at temperatures of > 2.300 °C. Silicon carbide is iron-free, angular and extremely hard.

Applications:

Reusable abrasive

Grinding, lapping and polishing medium

Grinding wheels and grinding medium

Wear-resistant and refractory products

Blasting systems:

Pressure blast systems

Injection blast cabinets

Speciafication

| Typical physical properties | |

| Hardness | approx. 9 - 10 mohs |

| Grain shape | angular |

| Melting point | approx. 2300 °C |

| Specific gravity | approx. 3,2 g/cm3 |

| Bulk density (depending on granular size) | approx. 1,3 – 1,5 g/cm3 |

| Typical chemical analysis | |

| SIC | 98,00 % |

| Fe2O3 | 0,24 % |

| C-frei | 0,50 % |

| Magnetic particles | 0,12 % |

| Available sizes | |||

| FEPA | Average grain size | ||

| ds3-Factor max. μm | ds50-Factor μm | ds94-Factor min. μm | |

| F 230 | 82,0 | 53,0 +/– 3,0 | 34,0 |

| F 240 | 70,0 | 44,5 +/– 2,0 | 28,0 |

| F 280 | 59,0 | 36,5 +/– 1,5 | 22,0 |

| F 320 | 49,0 | 29,2 +/– 1,5 | 16,5 |

| F 360 | 40,0 | 22,8 +/– 1,5 | 12,0 |

| F 400 | 32,0 | 17,3 +/– 1,0 | 8,0 |

| F 500 | 25,0 | 12,8 +/– 1,0 | 5,0 |

| F 600 | 19,0 | 9,3 +/– 1,0 | 3,0 |

| F 800 | 14,0 | 6,5 +/– 1,0 | 2,0 |

| F 1000 | 10,0 | 4,5 +/– 0,8 | 1,0 |

| F 1200 | 7,0 | 3,0 +/– 0,5 | 1,0* |

| * at 80% | |||

Other grain sizes can be produced if required. | |||

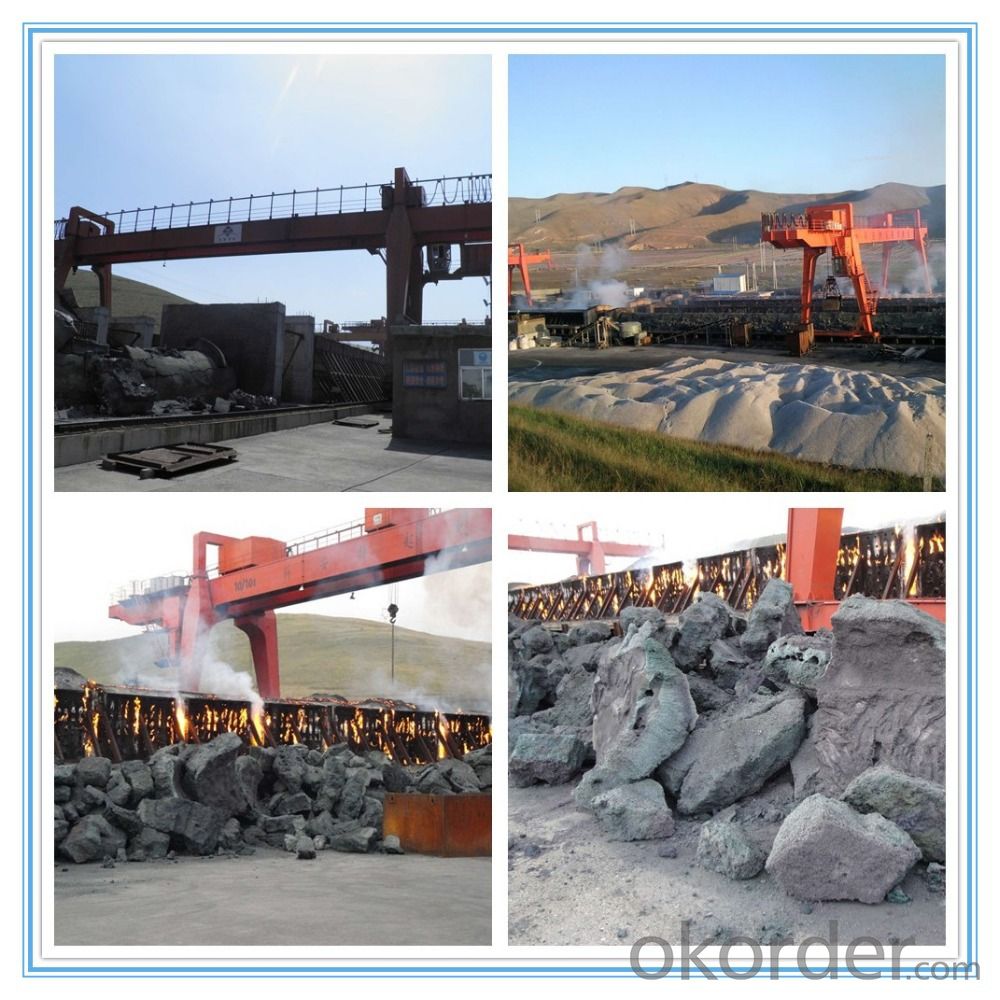

Factory and Package

Metallurgical Refinery

Grain Factory

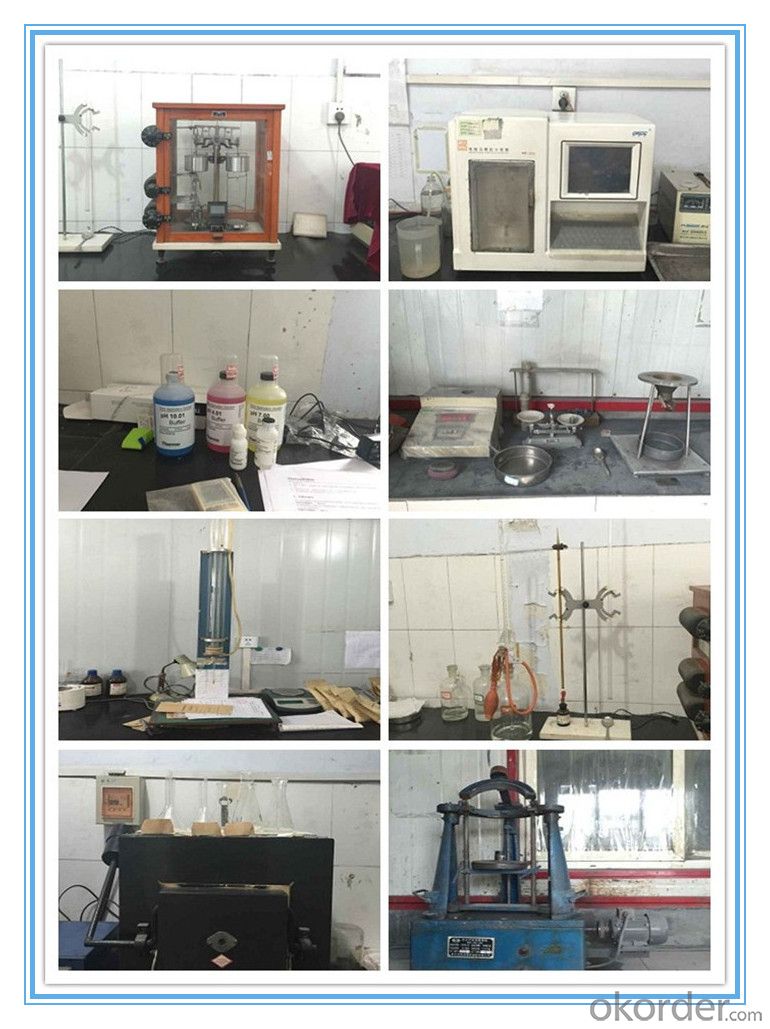

Package

Equipment

FAQ

1 Your production capacity?

A: 3000 ton every month.

2 Will the free sample be provided for us?

A:We will provide free sample about 1 kg.

3 Did you have your own mancfactory?

A:Yes,We have.

- Q:What's the difference between refractory metal raceway and fireproof raceway?

- Hello, I'm very glad to answer your question. As far as I know, anti-fire groove box is made by the polymerization reaction of high polymer material and halogen-free flame retardant polymeric material. It possesses excellent mechanical properties and environmental protection property, nice appearance, and diversified colors. As a kind of fully enclosed cable bridge, it is applicable for communication signals, and laying of computer cables and control cables of highly sensitive systems. When used in heavy corrosive environment and outdoor dust environment, it has good protective effect on cables. It boasts many advantages of fire retardance (fire resistance rating is above B grade), corrosion resistance, anti-aging, high strength, light weight, and easy installation. Hope my answer is helpful for you. Hope my answer can be accepted.

- Q:The fire prevention board line is made of what material?

- Crural line: wooden, in the market, there are sjoiner woodblock, peach wood and artificial engraving. The second classification is stone and the most used one is the marble graved or ceramics well-made one is taken as the first choise. Its price is a little bit expensive than the wooden one, but also a suitable choise. Condole supports: It has various category. The general furniture choose plaster and anti-firing plate and the other also have a choice of steel. You can make a suitable choice according to the need. If it is contracting project, it depends on your project specific plan and funds plan. In a word, beauty and harmony should be given priority since it is the source of design.

- Q:How long is the fire resistance time of the AAAfire resistance rolling shutter door?

- How long is the fire resistance time of the AAA fire resistance rolling shutter door?

- Q:which kind of refractory is used in golden smelting furnace? How about his using temperature

- generally the price of the quartz sand refractory material is higher and the temperature can meet the requirement of 2000 degree.

- Q:How can the furnace be replaced after the gasifier or water wall is replaced with refractory material?

- The furnace shall be made according to the type of refractory and the moisture content and the type of bond. Pay special attention to the discharge of free water and crystalline water, not too fast to prevent cracks!

- Q:who knows how to classify the fire resistant levels of fireproofing material?

- Materials used in construction are called construction materials. The combustion performance of construction materials refers to all physic and chemical changes happened when burning or contacting fire, the properity is measured by combustibility of material surface and flame transmission, heating, smoke,charring, weightlessness, and the producing of toxicity resultant. Our national standard GB8624-97 classifies the combustion performance of construction materials into following several levels. Class A: Incombustible building material, class B1: Nonflammable building material, class B2: Combustible?building?materials, class B3: Inflammability construction materials, generally speaking: first fire resistant level construction is the mixed construction of reinforced concrete structure or brick wall and steel concrete structure; second fire resistant level construction is the steel structure roof truss, reinforced concrete column or mixed structure made by brick wall; third fire resistant level construction is the wood and brick made by wooden roof and brick wall; fourth fire resistant level one is the combustible?structure made by wooden roof, hard-comnustible component wall.

- Q:What is molten silicon? What refractoriness do refractories made by it have? What properties of using does it have?

- Molten silicon can be called quartz glass, which shows an amorphous silicon state. It is a liquid fusion at above 1723 degree and is an ultra-cooling state at low temperatures. It is not generated in refractories, but generated in the matrix, showing liquid state at a high temperature capable of buffering the stress with somewhat binding properties. If quartz glass is used as refractory, its function are melrly these ones. (These are what I konw for reference only.)

- Q:About the market issues of thermal insulation material and refractory material.

- In fact, the thermal insulation material produced by the Sichuan-Benniao Hing construction company is very good, you can get the company's information just by inputing the Sichuan-Benniao Hing construction company into Baidu

- Q:How to distinguish the construction fire-proof material rating?

- Currently the national standards divide building materials as follows: A1, A2, B, C, D, E, F. External wall thermal insulation fire?rating can be basically divided into: A1, A2, B1, B2, B3 and other levels. Class A is non-combustible, class B1 flame retardant, class B2 combustible, class B3 flammable. Combustion performance grades of building materials and products are divided into class A1, A2, B, C, D, E, F. And grading of flooring materials and pipeline thermal insulation materials is also stipulated separately, whose combustion performance grade is distinguished by the subscript fl and L respectively. ie. Combustion performance grades for ordinary building materials and products are A1, A2, B, C, D, E, F; combustion performance grades for paving material are Alfl, A2fl, Bfl, Cfl, Dfl, Efl, Ffl; combustion performance grades for pipeline thermal insulation material are A1L, A2L, BL, CL, DL, EL, FL.

- Q:It the Special Fire-Proof Material belonged to ceramics? Is there a national standard of the Special Fire-Proof Material?

- The fiber and reinforcing material of the metal ceramic is also belonged to the Special Fire-Proof Material. ~~~~GB is too much trouble, GB online should ~~~ Lei Bao Refractories for you. The high temperature inorganic coating. 5. The refractory compound. 3. The high melting point oxide. You can search it on the internet according to the classification~~~~ The special refractories can be divided into five categories: 1. metal ceramic

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Black Silicon Carbide for Abrasives and Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords