Black PP Geogrid with CE certificate for Road construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

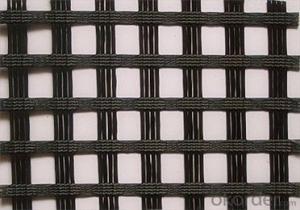

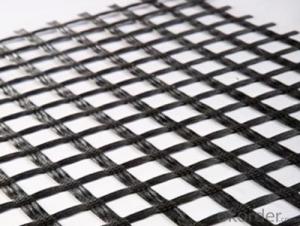

Structure of Black PP Geogrid Description:

Black PP Geogrid is with polypropylene, high density polyethylene as raw materials, made by special extrusion, two-way stretch.It Can reduce structural fill, uniform load distribution, and has high two-way tensile modulus and tensile strength, high mechanical damage ability, endurance ability

Main Features of Black PP Geogrid :

Black PP Geogridcan be used to enhancement of permanent bearable toft including roads and railways embankment, slopes, tunnel, airfields, parks, docks and ground which cargo lays on and their main usage are as follows:

Enhance the bearing capacity of road foundation and extend the duration of roads.

Prevent road surface from collapse, crack and being dirty.

Be convenient for construction, timesaving and cut down the cost of maintenance.

Prevent tunnel from crack occurring

Further solidity slopes to proof water and soil from losses.

Reduce the surface thickness of the ground.

Consolidate the net for growing grass on the slopes so as to stabilization surrounding virescence.

Be used for artificial top net of mines instead of metal ones.

Black PP Geogrid Images

Black PP Geogrid Specification:

| Specifications | Tensile strength(KN/m) | Tensile strength at 2% elongation | Tensile strength at 5% elongation | Nomianal elongation | Products in the range of coal mine | Max peel strength at welding point | ||

| GSJ30-30 | ≥30.0 | ≥10.0 | ≥20.0 | ≤12 | Fire out time from outer flam(s) | Surface resistivity | ≥30.0 | |

| GSJ40-40 | ≥40.0 | ≥20.0 | ≥25.0 | ≤3 | <1×109 | |||

| GSJ50-50 | ≥50.0 | ≥17.0 | ≥34.0 | |||||

| GSJ60-60 | ≥60.0 | ≥22.5 | ≥40.0 | |||||

| GSJ80-80 | ≥80.0 | ≥28.0 | ≥56.0 | ≤13 | ||||

| GSJ100-100 | ≥100.0 | ≥35.0 | ≥70.0 | |||||

| GSJ120-120 | ≥120.0 | ≥60.0 | ≥90.0 | |||||

| GSJ150-150 | ≥150.0 | ≥52 | ≥104.0 | |||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q:Are geogrids resistant to hydrostatic pressure?

- Yes, geogrids are resistant to hydrostatic pressure. They are designed to provide structural support and reinforcement to soil, helping to distribute and reduce the pressure exerted by water or other fluids.

- Q:Can geogrids be used in stabilization of mine tailings ponds?

- Yes, geogrids can be used in the stabilization of mine tailings ponds. Geogrids are commonly used in civil engineering for soil stabilization and reinforcement. They can provide strength and stability to the soil, preventing erosion and minimizing the risk of slope failure. In the context of mine tailings ponds, where the soil is often unstable and prone to erosion, geogrids can be an effective solution for stabilizing the area and preventing environmental hazards.

- Q:What are the long-term effects of using geogrids?

- The long-term effects of using geogrids include improved soil stability and increased load-bearing capacity, reduced soil erosion and sedimentation, enhanced pavement performance, and prolonged lifespan of infrastructure projects. Additionally, geogrids can contribute to cost savings through reduced maintenance and repair needs.

- Q:How do geogrids improve the stability of levees?

- Geogrids improve the stability of levees by providing reinforcement and increased tensile strength to the soil. These grid-like structures are placed within the levee's soil layers, creating a stable and cohesive system. The geogrids distribute the applied loads more evenly and prevent soil erosion, enhancing the overall stability and strength of the levee structure.

- Q:Classification of plastic geogrid

- 2, to highlight the advantages of geogrid is deformation under sustained loading (creep) tendency is very small, creep strength is much better than other materials geogrid, plays an important role in improving the service life of the project.3, the mesh grille and soil interlock and interlock function, constitute an efficient stress transfer mechanism, so that local load can be quickly and effectively spread to a large area of soil, to reduce the local failure stress, improve the service life of engineering.Three, the application of one-way plastic geogrid:Unidirectional plastic geogrid is a kind of high strength geosynthetics. Widely used in dams, tunnels, docks, highways, railways, construction and other fields.

- Q:Geogrid GSZ 100 50/PP what does it mean

- 100/50 is vertical and horizontal, a 100KN is a 50KN means, is a special model,

- Q:What is the effect of junction strength on geogrid performance?

- The effect of junction strength on geogrid performance is significant. A stronger junction ensures better interlocking and connection between the geogrid's components, leading to enhanced load distribution and resistance against installation stress and long-term deformation. It allows the geogrid to effectively restrain and stabilize the soil, improving overall geotechnical performance and longevity.

- Q:How do geogrids help in reducing the risk of soil compaction?

- Geogrids help in reducing the risk of soil compaction by providing reinforcement and stability to the soil. They distribute the load evenly and prevent excessive pressure on the soil, thereby reducing the chances of compaction. Additionally, geogrids enhance the load-bearing capacity of the soil, allowing it to withstand heavier loads without compacting.

- Q:What is the difference between uniaxial and biaxial geogrids?

- Uniaxial geogrids have strength and stiffness in one direction, making them suitable for applications requiring reinforcement in a single direction. Biaxial geogrids, on the other hand, have strength and stiffness in two perpendicular directions, allowing for reinforcement in multiple directions. This makes biaxial geogrids more versatile and applicable to a wider range of projects.

- Q:What are the limitations of geogrids?

- Geogrids have a few limitations that need to be considered. Firstly, they are not suitable for all types of soil. They work best in cohesive soils and may not be as effective in non-cohesive or sandy soils. Secondly, geogrids have limited resistance to chemical degradation, so they may not be appropriate in environments with high chemical exposure. Lastly, geogrids are not designed to withstand heavy loads or provide significant structural support on their own, so they should be used in conjunction with other reinforcement techniques for optimal performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Black PP Geogrid with CE certificate for Road construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords