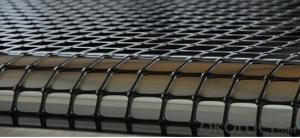

Black Poly HDPE Geogrid and PP Biaxial Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction of Plastic Geogrid

Plasticgeogrid is made of high molecular polymer after extruded and laminated and punched into regular mesh before longitudinal stretching.

The material on the longitudinal and transverse has great tensile strength, this kind of structure in the soil can also provide a more effectively undertake the chain and the spread of the thought system, suitable for large area of permanenet bearing foundation reinforcement.

2. Features of Plastic Geogrid

1). With high tensile strength in longitudinal and transverse directions

2).This structure can provide an chain system of more effective force bearing and spreading for the soil.

3. Application of Plastic Geogrid

Suitable for all kinds of dam and roadbed reinforcement, slope protection, The cave walls reinforcement, large airport, parking lot, wharf freight yard and other permanent bearing foundation reinforcement.

1). Increase road (ground) base bearing capacity and prolong the service life of road (ground).

2). Prevent road (ground) surface collapse or crack, ground is beautiful and tidy.

3). Construction is convenient, save time, effort, and shorten the construction period, reduce maintenance costs.

4). Prevent culvert crack.

5). Enhance soil, prevent soil erosion.

6). Reducing cushion thickness, saving the cost.

7). To support the stability of slope planting grass mat afforest environment.

8). Can replace the metal mesh, used in coal mine underground false roof net.

4. Technical Data and Specification of Plastic Geogrid

Spec Item | TGSG15-15 | TGSG20-20 | TGSG30-30 | TGSG40-40 | TGSG45-45 |

Longitudinal Tensile Strength ≥(KN/m) | 15 | 20 | 30 | 40 | 45 |

Transverse Tensile Strength≥(KN/m) | 15 | 20 | 30 | 40 | 45 |

Longitudinal Elongation≤(%) | 15 | ||||

Transverse Elongation≤(%) | 13 | ||||

Longitudinal Strength at 2% Strain ≥(KN/m) | 5 | 7 | 10.5 | 14 | 16 |

Transverse Strength at 2% Strain ≥(KN/m) | 5 | 7 | 10.5 | 14 | 16 |

Longitudinal Strength at 5% Strain ≥(KN/m) | 7 | 14 | 21 | 28 | 32 |

Transverse Strength at 5% Strain ≥(KN/m) | 7 | 14 | 21 | 28 | 32 |

Remark | Roll Length:50m Roll width:1~4m | ||||

5. RFQ:

1) What's your payment terms?

T/T, L/C at sight, etc

2) What's your delivery time?

Within 15-20days against your deposit or original L/C received

3) Can you accept third party test?

Yes, we can accept it totally, SGS, BSJ, etc are no problem for us.

- Q:What is a plastic geogrid? What do you say is a one-way geogrid?

- It can be divided into two kinds, one way and two way.

- Q:Are geogrids suitable for use in mechanically stabilized retaining walls?

- Yes, geogrids are suitable for use in mechanically stabilized retaining walls. Geogrids are commonly used in these types of walls to provide reinforcement and improve stability. They help distribute the loads and reduce lateral movement, enhancing the overall strength and performance of the retaining structure.

- Q:What is the single geogrid 60kN/m

- 60kN/m refers to the direction of force.

- Q:Are geogrids suitable for use in slope reinforcement during excavation?

- Yes, geogrids are suitable for use in slope reinforcement during excavation. Geogrids provide stability and reinforcement to slopes by distributing the load and preventing soil erosion. They are effective in strengthening the slope, reducing the risk of landslides, and improving overall safety during excavation operations.

- Q:What factors should be considered when selecting a geogrid?

- When selecting a geogrid, several factors should be considered. Firstly, the specific application or purpose of the geogrid should be taken into account, as different geogrids may have varying strengths and properties. The soil conditions and load requirements of the project also play a crucial role in determining the appropriate geogrid, as these factors can affect the geogrid's performance and effectiveness. Other considerations include the installation requirements, durability, and long-term performance of the geogrid. Additionally, considering the cost-effectiveness and environmental impact of the geogrid can also be important factors in the selection process.

- Q:What are the differences between three different types of geogrids?Unidirectional geogrid, two-way geogrid plastic, geogrid, warp knitted geogrid and fiberglass geogridWhich is the best place in Guangzhou geogrid Zhejiang geogrid in Tianjin?

- The geogrid is divided into plastic geogrid according to the material

- Q:How do geogrids improve the load distribution in foundations?

- Geogrids improve load distribution in foundations by effectively spreading the load over a larger surface area. This is achieved through their high tensile strength and stiffness, which allows them to distribute and transfer the load from the foundation to a wider soil area, reducing stress concentration points. By doing so, geogrids help prevent differential settlement and soil failure, enhancing the overall stability and performance of the foundation.

- Q:Are geogrids effective in reducing pavement rutting?

- Yes, geogrids are effective in reducing pavement rutting. Geogrids provide reinforcement to the pavement structure, distributing loads and reducing the stress on the pavement surface. This helps to prevent the formation and progression of rutting, resulting in improved pavement performance and longevity.

- Q:What is the recommended geogrid connection method for specific applications?

- The recommended geogrid connection method for specific applications depends on factors such as the type of soil, slope angle, and expected load conditions. Some common geogrid connection methods include mechanical connectors, welded connections, and soil wrap-around techniques. It is important to consult with a geotechnical engineer or follow manufacturer's recommendations to determine the most suitable connection method for a specific application.

- Q:What is the tgsg15-15 geogrid

- The single belt is formed by the longitudinal and horizontal spacing or the clamping arrangement, and the welding joint is formed by adopting the welding technology of special strengthening bonding to weld the joint.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Black Poly HDPE Geogrid and PP Biaxial Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords