Black Annealed Wire Soft Quality&Hard Quality Factory Pirce

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Black Annealed Iron Wire Description:

Black Annealed Iron Wire is Q195, element composition is as follows: C≤0.06; S≤0.023; Si≤0.09; Mn≤0.32; P≤0.025.Because This type of wire rod has less Impurities, Q195 is fit for drawing.

Black Annealed Iron Wire is very good for Chain link fence, fencing mesh, gabion mesh box production and for construction business as tire wire, binding wire and galvanized wire raw material production. Black Annealed Wire is mainly processed into coil wire, spool wire or big package wire. Annealed wire is used as tie wire or baling wire in building, parks and daily binding. Besides, black annealed wire is mainly used as industrial wire, construction wire, industrial bale tie wire and constructional tie wire, etc.

2.Main Features of Black Annealed Iron Wire:

• Durable

• Practical

• Versatile

• Use widely

• Inexpensive

3. Black Annealed Iron Wire Images

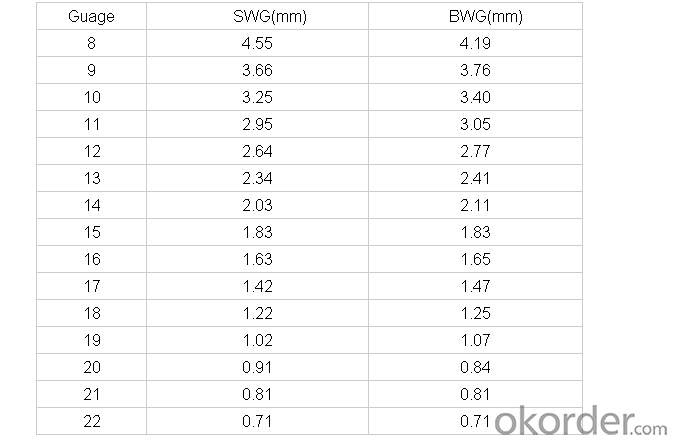

4.Black Annealed Iron Wire Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. Q: Are you a factory or trading company?

A: We are a factory, will offer you best price and guarantee the quality.

2. Q: Can I get some samples?

A: Yes, we are honored to offer you free samples.

3. Q: How does your factory do regarding quality control?

A: We have strict control in testing of raw material, production process and final process. Only qualified products can be sent out.

- Q:I'm installing a remote start system in my car, but I can't find the tach wire. Does anyone know what harness it is located in, and what color the cable is? I've looked over the diagrams, but I can't seem to find the cable that runs to the tach guage.

- Tachometer blue wire AC under the distributor or side

- Q:instead of using the wire its self could you put a terminal at the end of your audio wire and connect it to the amp, for your car audio. Because I just ordered 1/0 awg wire, but I don't think the wire will fit on the amp, so could I put a Y terminal at the end of my 1/0 gauge wire and connect that to my amp?

- Depends okorder ... Another option would be a distribution block that allows a 0-gauge input and 4-gauge outputs. You could use this to reduce the wire size before the amplifier connection.

- Q:How can I repair an enamel coated headphone wire? In other words, how can an enamel coated wire be reconnected; i.e. how is the enamel coating stripped off, and what can I use to recoat it so that it won't short?

- Strip off the coating to expose bare metal where you would to slice (reconnect) new wires. Twist them or soldier them together. The wires will not short unless they come in contact with electricity-conducting materials, including human flesh. Hardware stores sells paint just for wires, but you don't have to go such extremes. Just put some tape it or cover it with any other non-conductive materials.

- Q:What type of wire do i need to install a normal inside wall outlet? Do i have to use solid copper wire?

- Buy AWG # 14X2 cable inside includes one more bare copper wire for grounding. Solid single conductor is the common product.

- Q:If not, then, in experiments, why must a wire always be straight?

- The resistance of a wire results from: (1) the conductivity,σ, of the material used to construct the wire; (2) the length, L, of the wire; and (3) the cross-sectional area,S, of the wire. R = L / σS Bending the wire might theoretically crimp the wire and affect the cross-sectional area. However, as a practical matter, this is not a factor. Most likely, you are required to keep the wires straight for the sake of neatness. It makes it easier for your instructor to follow the logic of your circuit.

- Q:i have a 92 saturn and bought the wire harness, i put all the wires together and all that turned on was the theft light that comes on when you take off the face after that i tried putting the red and yellow wires together and it worked, just without the key having to be in the ignition and i think that is why the stereo gets so hot so can youall tell me how to wire it correctly?

- if leith was paying attention he would of realized you already have the wire that goes straight to the battery. YOU need a wire to hook up to the red one that comes on with the ignition. if the wire thats supposed to work for this dont for some reason you can 1. hook it into the fuse box with something that comes on with the key or 2.you can simply hook the yellow wire and a 4 foot peice of 12 g wire to the one that gives it power then with your extra wire run itout on the dash for a toggle switch and run that back to the red wire and remember to turn it off or you will have a dead battery in the morning :)

- Q:what does a #12 copper wire look like and waht does a #14 wire look like if you got pictures post a link thanks

- In recent years, much of the 12 gauge wire is being wrapped in yellow pvc, while the 14 gauge is still being wrapped in white. Side by side it's easier to tell. 12 is thicker and more difficult to work with, bend and such. Also, spools of wire have the gauge and other identifying characteristics laser printed on them at regular intervals.

- Q:When it is time to replace wiring in a building?

- When the demand for power increases. They're many form of wiring. Knob and tube, brown rag wire( no neutral) BX and Romex style. All depends on your needs. Knob and tube is extremely antiquated and can be dangerous. You could also consult an electrical company and have them go over your house with you and see what they say. Most companies can give you an estimate or diagnosis on the electric in your home for free

- Q:So I need to tap a few wires, and cut 1 wire and join it with another wire..What would be the best way to approach this? Here are the full instructions so you guys have an idea on what I'm trying to do.quot;On the TAN plug there is 1 ALL PINK(E7) wire you need attach the WHITE wire from your relay to that but don't cut the PINK wire just tap the WHITE into it.Next go the the GREY BCM plug there are 3 WHITE wires.

- The instructions seem pretty straight-forward. T-Taps and squeeze-connectors are basically the same thing; achieving the same results, which is to add a connection to an existing wire without interrupting the line. Just make sure you use the right size and type, meaning; don't use a low-voltage connector for a high-voltage application... You'd just fry it up. For the cut wires, I'd use crimp-connectors and some shrink-wrap. Again, using the correct connector. You can use wire-nuts, but the crimp-connectors are a more permanent fix. Good luck to ya.

- Q:Is it okay to solder wrapping wire to a mother board, I am just asking because the wires are called WRAPPING.

- except you're honestly helpful that the solder is lead unfastened, do no longer use it. Plumbing solder is ordinarily lead unfastened yet electric and sturdy sheet metallic solder pick no longer be. and that i'm uncertain how mind-blowing tin, the different important element of solder, is in terms of leaving black marks on the floor even however somewhat risk-free.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Black Annealed Wire Soft Quality&Hard Quality Factory Pirce

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords