Birch Material Film Faced Waterproof Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Model Number: plywood

· Usage: Indoor

· Grade: First-Class

· Main Material: Birch

· Formaldehyde Emission Standards: E1

· Plywood Type: 18-Ply Boards

· Size:: 1220X2440mm/1250X2500mm

· Density:: 500-750 kg/m³

· Thickness:: 2.0mm~30mm

· Core:: Poplar, Hardwood, Combi, Birch, eucalypts

· Face/back:: Okoume, Bintangor, Pencil Cedar, Maple, Ash, Oak and as your requested

· Glue:: MR,E1,E2,Melamine,WBP Phenolic

Packaging & Delivery:

Packaging Details: Inner packing: 0.2mm thick plastic bag Outer packing: pallets covered with plywood/carton, then steel taped for strength

Delivery Detail: 2 weeks after your deposit

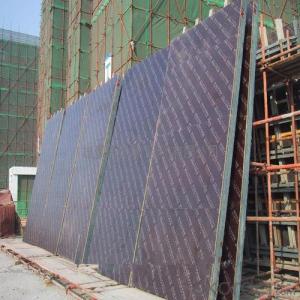

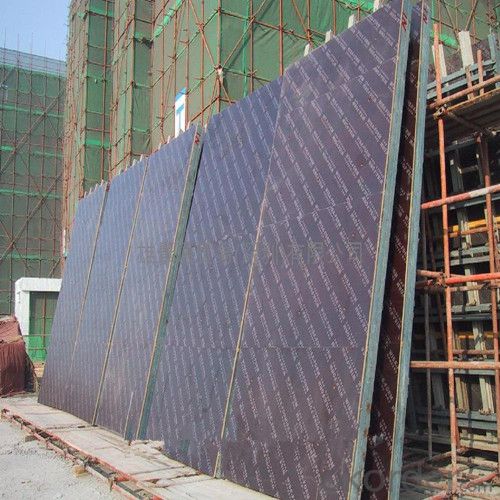

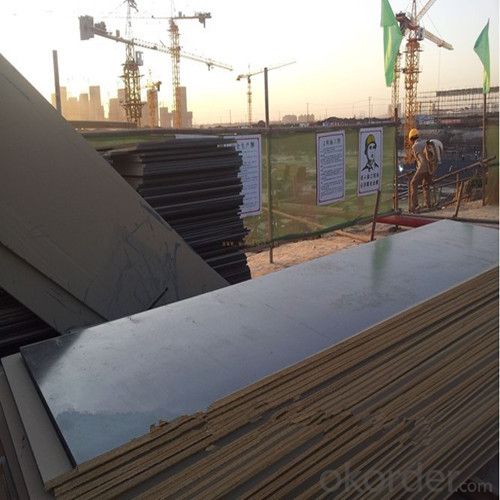

film faced waterproof plywood plywood prices

1.ISO9001:2008;CE;CARB

2.Face/Back: Black/brown/red/anti-slip film

3.Glue:E0,E1,E2,MR

4.Size:1220*2440/1250*2500mm

Detailed Product Description:

Place of origin | Shandong China | ||

Face&back | Okoume, Bintangor, Pencil Cedar, Keruing, Poplar, Birch, Pine, Maple, Hardwood, Ash, Oak and as your requested | ||

Core | Poplar, Hardwood, Hardwood, Combi, Birch, eucalypts, as your requirement. | ||

Size | 1220*2440/1250*2500mm and as your requirement | ||

Thickness | 2mm to 30mm and as for your requirement | 1/8 inch(2.7-3.6mm) | |

1/4 inch(6-6.5mm) | |||

1/2 inch(12-12.7mm) | |||

5/8 inch(15-16mm) | |||

3/4 inch(18-19mm) | |||

Thickness tolerance | 2-6mm: +/-0.2mm | ||

6-30mm: +/-0.3mm | |||

Grade | BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc. | ||

Glue | MR,E1,E2,Melamine,WBP Phenolic | ||

Moisture | 10%-15% | ||

Joint way | Overlap joint, end joint, scraf joint, finger joint | ||

Strength | High bending strength Strong nail holding | ||

Quantity | 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ | ||

Usage | construction, Furniture, decoration, packing. | ||

Certificate | ISO9001: 2000; CE; CARB | ||

Main market | Middle East, South Asia, South America, Africa | ||

Shipment & payment | |||

MOQ | One container | ||

Port | Qingdao | ||

Packing details | Inner packing: 0.2mm thick plastic bag Outer packing: pallets covered with plywood/carton, then steel taped for strength | ||

Delivery time | 2 weeks after your deposit | ||

Payment | T/T, 30% deposit, the balance against the copy of B/L, L/C at sight. | ||

Advantage | |||

Capacity: 6000 CBM per month | |||

Sample available | |||

high quality and competitive price | |||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q:Sandwich board moldy how to deal with

- If the mold is generally difficult to clean out, you can use some alcohol class wipe, the mold to erase, it is best to go online to buy a small amount of Ai Hao Seoul fungicide spray up to ensure that the sandwich board is not Re-moldy.

- Q:Steel structure plant color steel sandwich panel roof design fire resistance 0.5H, need to apply fire retardant paint

- Answer did not see the answer before the third floor, you adopt the third floor of the views of it

- Q:Color steel sandwich panel foam per cubic meter of weight is how much

- Color steel sandwich board phenolic foam bulk density can reach about 50 kilograms per cubic meter

- Q:New rock wool sandwich board polyurethane edge how much money one meter

- Do not do the fire to investigate or deal with either Yanmian board or polyurethane board price is the polyurethane invoice does not send about 130% of the price of rock wool

- Q:There is a phone call

- The price of polyurethane sandwich panels have the thickness of the polyurethane sandwich panels used and the color and thickness of the color steel plate to determine the price of its polyurethane sandwich panels. The common polyurethane sandwich panel specifications are 50,75,100,150,200 thick Of the price between 90-120 yuan. Manufacturers can see my picture, you need the above contact information. Here to tell you degree mother and give me a shield, and I easily I, to high score ah!

- Q:Color steel sandwich board how much money

- First, the color plate model: roof? Wall? ?????? Second, the core material (glass wool? Rock wool? Polyurethane? Polyphenylene extrusion), thickness, density ?????? Third, the color plate thickness, origin, coating, plating (aluminum) zinc content ?????? Fourth, the amount will also affect the price to a certain extent.

- Q:Is the sandwich panel toxic? Now we live with a sandwich board to do the house, listen to friends that sandwich board toxic, is it true?

- Sandwich panels are environmentally friendly materials, how many are a bit, no big problem, you can rest assured that use. But I would like to remind is in the color of the steel house, pay attention to the improper use of the kitchen to prevent fire. For the quality of sandwich panels, the world color steel is good to understand the next.

- Q:anxious! Will the polyurethane sandwich panels of various parameters, plant design!

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q:Because it was not promptly cleared, after the wind and sun, it is difficult to clear, because the area is relatively large, a little bit of clean up by hand very difficult, which experts have any good way not?

- 2. Board protection form: complex PVC protective film 【Features】 1. Advantages: good fire resistance, sound insulation better. Yanmian Caigang sandwich panel Features: Caigang rock wool composite board products for the A-class fire board 1. Good fire performance:

- Q:What is the difference between the ecological board and the sandwich board? Which is used to decorate better, what is the price? What are the top ten brands of the two boards?

- The ecological board is made of natural mineral stone powder and natural fiber as the basic raw material, through the inorganic gel technology modification process, through the mold, natural curing molding for the environmental protection and energy saving new materials, which does not contain formaldehyde, toluene inorganic natural environmental performance, Combined with the surface of the natural texture and sustained and efficient negative oxygen ion release, to achieve its natural properties of green building materials. Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Birch Material Film Faced Waterproof Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords