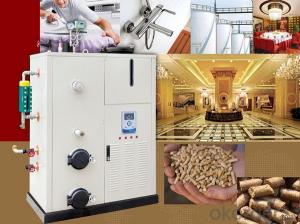

Biomass Pellet Hot Blast Stove Commercial&Risidental

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.10000~30000Kcal

2.920x450x890mm

3.Can be customized

4.Biomass Pellet Fuel

5.Apply to dry and heat for greenhouse,industry

Introduction

The released CO2 gas when boiler combusting can not only get rid of excess moisture inside the greenhouse, but also help plants for photosynthesis.

Key Features

Energy saving: in the first minute after power on, complete the process from ignition to combustion, heating rapidly.

Intelligent effort: microcomputer control system to control the automatic ignition, feeding and thermostat, just 1-2 times a day to refuel, almost no need of manual work.

Friendly to environment: completely full fuel combustion can achieve the effect of smokeless, dust-free and odorless.

Particularly apply to dry and heat for greenhouses, industries, enterprises.

Application Range

Widely used to heating in greenhouses, heating projects, industrial plants and civil buildings; preparation and drying for chemical and pharmaceutical industries; drying for sand and sand core in foundry industries, drying for abrasives tools, gauze and grinding wheel in abrasive industries; Baking paint and powder curing for automobile, motorcycle, container, appliance, tinplate printing and other industrial products in coating industries; heat setting, hot melts dyeing, baking, drying for wood.

Specification

| Project | Unit | GS-0.035 | GS-0.12 | GS-0.24 | GS-0.54 |

| Rated heating value | Kcal | 1-3×104 | 10×104 | 20×104 | 45×104 |

| Working pressure | MPa | ordinary pressure | |||

| Thermal efficiency | % | 85 | 91 | 91 | 92 |

| Induced draft fan | KW | / | 0.75 | 1.1 | 3 |

| Circulating fan | KW | 0.3 | 2.2 | 2 | 7.5 |

| Flue duct hole diameter | mm | Φ108 | Φ165 | Φ165 | Φ220 |

| Fir outlet | mm | 465x410 | 300x300 | 300x300 | 400x400 |

| Fir inlet | mm | 465x410 | dia300 | 300x240 | dia350 |

| Boiler weight | kg | 90 | 650 | 910 | 2080 |

| Fuel consumption rate | kg/h | 2.2-5.3 | 13.9 | 39.9 | 88.9 |

| Heating area | m2 | 100-300 | 700-920 | 1400-1800 | 2700-4500 |

| Air velocity | m³/h | 230 | 1264 | 2700 | 3166 |

| Boiler size: length | mm | 920 | 2075 | 2395 | 3130 |

| Boiler size: width | mm | 450 | 680 | 930 | 1000 |

| Boiler size: height | mm | 890 | 1200 | 1850 | 1720 |

| Silo size: length x width x height | cm | Silo internal | 50x40x60 | 50x40x60 | 60x60x80 |

- Q:If you want to promote the use of biogas, what needs to be done? What are the risks?

- Reconstruction of light management, as time passes, methane pool disease ridden".For farmers who have built biogas digesters, they believe that the pool was built, once and for all, the reconstruction of light management, heavy use of light maintenance. Therefore, they only know to build the pool after the ignition, no longer only after feeding, desulfurizer will no longer change; do not pay attention to the maintenance of a pipeline, the fault is not ruled out, in the course of time, the methane tank "ailing" cannot run until.

- Q:600 cubic meters of methane a day

- Biogas production is related to many factors, such as temperature, filler concentration, PH and so on, according to the data provided by the company

- Q:How to extract diesel

- Biodiesel with Jatropha procedure is as follows: first oil from Jatropha oil pressing; adding sodium hydroxide in the oil, is separated into a liquid fatty acid salt made by the rainbow Straw oil with methanol; after heat treatment, can generate glycerol sediment and diesel

- Q:What is the use of Biogas

- Biogas can be used for lighting, heating, cooking, heating, etc.. Gas construction is an important way to promote rural renewable waste into clean energy

- Q:What is the odor in the marsh gas

- Biogas contains a smell of gas, protein nitrogen, sulfur, nitrogen by microbial fermentation will produce ammonia, sulfur will produce hydrogen sulfide, these two gases are smelly

- Q:Is there a subsidy for biodiesel

- There is a value-added tax that is incremental policy

- Q:I have a gas pool, just to boil water, I think it has what purpose

- Three, the state to promote the use of biogas policy. Countries to promote the use of biogas is a way of policy subsidies. Each farmer to build a biogas digester, the state will give some subsidies. It is understood that in the provinces of energy office documents and government departments on the popularization of biogas on popularizing the biogas information report, only mentioned biogas digester, instead of a file and report mentioned the biogas tank, now there is not a local government called on popularizing the technology of biogas tank. As a result, the use of biogas tanks is not like some corporate propaganda, get government support. A technology must be based on mature, to be improved to the market. Is not how good you say it is good, if you really can make the majority of users of the biogas tank is convenient, practical, then this product has vitality, the state authorities to develop relevant policies.

- Q:When the methane in the methane tank is not enough, there is no use of water in the pond

- The fermentation of biogas fermentation materials suitable is the material basis to produce biogas digesters, in order to ensure the start and fermentation fermentation of raw materials sufficient and stable, in before feeding, fermentation of raw materials need to choose the suitable organic nutrition of cattle and pig manure, sheep manure and so do the start. These raw materials are fine particles, containing a lot of low molecular weight compounds, carbon and nitrogen ratio is less than 25:1, which is suitable for the fermentation of carbon and nitrogen ratio, after entering the pool to start fast, good gas production. Do not start with chicken manure, manure, these raw materials in the case of less methane bacteria, the material is easy to acidification, fermentation can not be normal. The fermentation concentration of 3, the first loading the biogas digesters to fit the first feeding amount should be 80% if the volume of the pool, because of the temporary lack of raw materials, one-time feeding can not meet the requirements of feeding quantity (most household biogas digester will not have such ample raw materials), and more than the water inlet and outlet 15 cm, closed fermentation fermentation. The first feeding concentration using 6%--10%, if the proportion of raw materials and water in the methane tank is difficult to estimate, would rather thin, not too strong, otherwise easy acidification.

- Q:What is the best methane pool

- methaneThe utility model relates to a fermentation device,High quality, high strength, acid and alkali resistance, aging resistance, etc.After a large high precision, intelligent high temperature welding equipment combination. Compared with the traditional biogas pool, with high technological content, environmental health, novel structure, beautiful appearance, unique technology, light weight, safe and reliable use, management, maintenance, easy to move, easy to transport, economic and durable, applicable to a wide range the advantages, is a kind of innovation in the development of biogas technologyEquipment of fermentation biogas. It integrated into the modern high technology, to capture software digesters (bags) produced many technical difficulties, successfully solved some deficiencies and defects of the traditional biogas pool, the majority of rural household consumers, many livestock is deepAnd townSystem biogas engineering users favor and praise

- Q:I spent more than and 10 years with biogas digesters, is built under the pigsty, due to want to re build a house, do not intend to use, how to deal with security, please say in detail, thank you

- Open fire, ventilation even if no danger, do not want to keep filling in, want to keep with the method of drainage, water to fill and drain fens

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Biomass Pellet Hot Blast Stove Commercial&Risidental

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords