Bilateral Metal Hardware Sealed Electric Butterfly Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

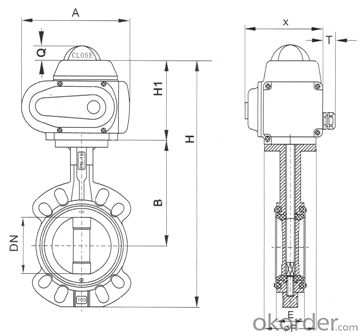

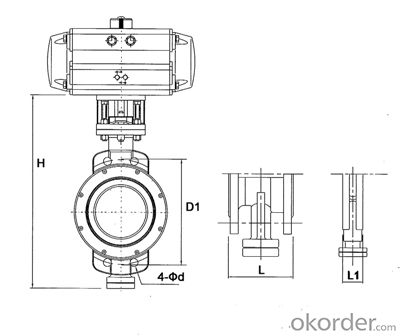

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:What does 3/4''mean in the name of the valve?

- Upstairs answer is very clear, 3/4 refers to the caliber of the valve is 3/4 inches, equal to the national standard DN20, (20mm) commonly known as 6 points. The most common family is 1/2, equal to DN15, commonly known as 4 points. Another marked 1.6 refers to the pressure of 1.6Mpa., equal to 16Kg, to bear the pressure.

- Q:What's the advantage of using three way valves?

- A valve can be used to turn on and off and change the flow direction of the medium.

- Q:What does the valve stroke mean?

- The distance from one position to another. Usually in the first position of the cut position, the second position is put through the position. Unless the valve has 3 positions.[1] to determine the stroke of the valve is the valve and valve two, closing stroke of its opening height, the valve opening height to diameter of the valve is fully open, 1/3, so the opening height is part size below the path + gate is closed.[2] valve: valve (Famen) is a fluid conveying system control components, with a cut-off, regulation, diversion, to prevent reverse flow, voltage regulation, shunt or overflow, pressure relief and other functions. Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q:Symbols for all types of valves

- In addition to the throttle valve (L) valve (H) valve (U) valve (Y) of the four types of valves, the other is according to the first letter of the easy to remember the four valve but also second word the first letter and the other valve is repeated with the first letter of a very good record I was just valve knowledge I hope to help you!

- Q:There is a rectangular hole in the valve core, which the heating company repairman gives to the bolt. Rest assured, I do not want to heating, but my indoor temperature is low, I suspect that the repairman mischief, deliberately give me lower temperature

- The heating valve refers only to a radiator system accessories, is a type of valve, the valve commonly used heating system on the market is mainly divided into: gate valve, ball valve, safety valve, balance valve, globe valve, regulator valve, relief valve, pneumatic control valve.

- Q:What is the use of each brand in the super high-rise, commercial complex, hotel? Price comparison of each brand? In the general valve, balance valve, electric valve, who did the best? Any knowledge about the valve, please ~ ~ thank you for your generous with your criticism

- Tyco doesn't know much about it. It's often written in the bidding documents, but there are very few actual purchases, so I don't evaluate it any more. The strongest of the balance valves is the TA (Swedish). He was the originator of the balancing valve. Super high-rise complex, the hotel part, you mention these kinds of valves are applied a lot.

- Q:What is the flow medium of the valve?

- Just like the one in your bottle, then the medium in your bottle is water

- Q:What are the general types of valves?

- Valve is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Function and use(1) cut off categories: such as gate valve, globe valve, plug valve, ball valve, butterfly valve, needle valve, diaphragm valve and so on. Cut off valve, also known as closed-circuit valve, stop valve, whose role is to connect or cut off the pipeline medium.Check valves, also known as check valves or non-return valves, check valves belong to an automatic valve, its role is to prevent the pipeline medium backflow, to prevent the pump and drive motor reversal, as well as the leakage of container media. Pump water off the bottom valve check valve also belongs to class.The function of the relief valve is to prevent the medium pressure in the pipeline or device from exceeding the required value so as to achieve the purpose of safety protection.Control valve, throttle valve and pressure reducing valve, its role is to regulate the media pressure, flow and other parameters.(2) vacuum type: such as vacuum ball valve, vacuum flapper valve, vacuum air charging valve, pneumatic vacuum valve, etc.. Its function is to change the direction of the air flow in the vacuum system, adjust the air flow rate, cut off or connect the vacuum system of the pipeline, and the component is called the vacuum valve.(3) special uses such as pigging valves, vent valves, drain valves, exhaust valves, filters, etc.. The exhaust valve is an essential auxiliary component in the pipeline system. It is widely used in boilers, air conditioners, petroleum, natural gas, water supply and drainage pipelines. Often installed in the commanding heights or elbows, etc., to exclude excess gas pipeline, pipe road to improve the use of efficiency and reduce energy consumption.

- Q:I used to do pumps, and now feel the future of the valve better, looking for a valve to do proxy, but my own economic strength is not good, I do not know if there is no possible to do?

- As the saying goes, the valve does not break up. The type of valve is too much, I do not know what you want to proxy valveIf you want to take advantage of the price, please go to Tianjin, or go to the township of Henan valve to see the followingIf you want to take advantage of quality, please go to Henan's Gaoshan Valve Co., Ltd., Yu Ming Valve Co., Ltd., Zhengzhou high and low pressure valve Co., Ltd... I am the valve distributor in Shenyang

- Q:What valve is the DN 25?

- This is only the aperture of the valve. It does not represent the form of the valve.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bilateral Metal Hardware Sealed Electric Butterfly Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords