Big Flowrate Single Stage Double Suction Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Big Flowrate Single Stage Double Suction Centrifugal Water Pump

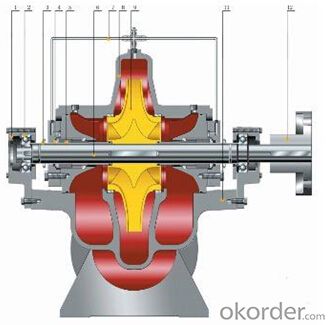

1.Structure of Big Flowrate Single Stage Double Suction Centrifugal Water Pump Description

The Single Stage Double Suction Water Pump is designed for pump station, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of Big Flowrate Single Stage Double Suction Centrifugal Water Pump

• Compact structure

• Attractive design

• High efficiency, steady performance

• big capacity, medium pressure

• High concentricity of components

3. Big Flowrate Single Stage Double Suction Centrifugal Water Pump Images

4. Big Flowrate Single Stage Double Suction Centrifugal Water Pump Specification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

5.FAQ

①What is the applications?

Besides irrigation and drainage pumping Station, the Single Stage Double Suction Split Casing Centrifugal Pump also can be used for Circulation water for air-condition, water supply for industry and building, and other waterworks.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q:What is the pump delivery? What's the difference between years and years?

- Secondly, the landlord asked the question, although I did not go to the insurance company to practice the operation, but to my four years of learning, as well as internship experience, or can help you analyze, and I hope to help you.Pay is a one-time payment of premium -- all wholesale D sea n

- Q:You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- Looking forAlignment means the position of the center of rotation of the pump and motor so that they are in the same line.At least three times after the initial installation or after installation:

- Q:How can the submersible pump level meter be connected?

- Install liquid level controller, two position liquid level sensor, controller to buy manual, wiring according to wiring diagram.

- Q:What is the pump, how to classify, mainly used in where?

- 1. vane pumpThe impeller pump is driven by the impeller to rotate the liquid at high speed and transfer mechanical energy to the transported liquidAccording to the pump impeller and runner structure characteristics can be divided into different:1) centrifugal pump2) axial flow pump3) mixed flow pump4) vortex pumps3. jet pumpA high velocity jet produced by a working fluid is used to eject the fluid, and then the energy of the ejected fluid is increased by momentum exchange

- Q:What is the minimum continuous flow of a pump?

- Quality solutionsMinimum flow of pump, minimum continuous flow of pumpIn order to ensure the proper use of the pump and the normal operation of the pump manufacturer will indicate the minimum pump in the sample of the continuous operation flow, the correct selection or use to warn or instruct users. According to the provisions of the API standard, the minimum continuous flow into the minimum continuous stable flow and continuous flow. Most small thermal limit(1) the minimum continuous stable flow.API standard specifies the minimum continuous stable flow refers to the vibration limit does not exceed the standard set by the pump can work normally. The minimum flow pump at small flow rate, there will be noise and vibration increase, API of this provision is to ensure that the service life of the pump, avoid due to improper operation of the pump caused by the adverse effects.

- Q:Fire hydrant pump button, under what circumstances do not need to install?

- The installation of hydrant pump buttons depends on the type of water supply:(1) municipal water supply; (in this case, do not have to install)(2) there is a fire pump; (must be installed)

- Q:What are the characteristics of a vertical multistage centrifugal pump?

- Vertical multi-stage centrifugal pump is cast iron, the advantage is that the price is cheap, the disadvantage is bulky and power consumption.

- Q:Why should the pump be closed when the centrifugal pump is started?

- On the other hand, the water on the pipe of the inlet pipe of the pump is stationary before the pump is opened, such as the sudden acceleration, and the water behind it can not keep up, which will cause the pressure of the inlet to drop suddenly and vaporize the water, and the centrifugal pump will be evacuated. (because of the centrifugal pump is rotating centrifugal force generated by the pump, leaf water and steam driven (gas) quality is very light, according to F= Ma, the centrifugal force is small, the pump can not be water sent).

- Q:What is a positive displacement pump? He Weizheng displacement?

- The principle and structure of positive displacement pumps are similar to those of hydraulic motors. Positive displacement is the pump outward to provide flow and pressure, that is, conventional pumps. A negative displacement pump is a hydraulic motor that rotates by external pressure and flow.

- Q:Filter backwash pump for what use, what is the principle of work ah?

- But the reverse cleaning can not completely regenerate the filter medium, or there will be some impurities remain, when the regeneration of residual impurities (pressure drop) to set the value, you need to replace the filter (filter media).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Big Flowrate Single Stage Double Suction Centrifugal Water Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords