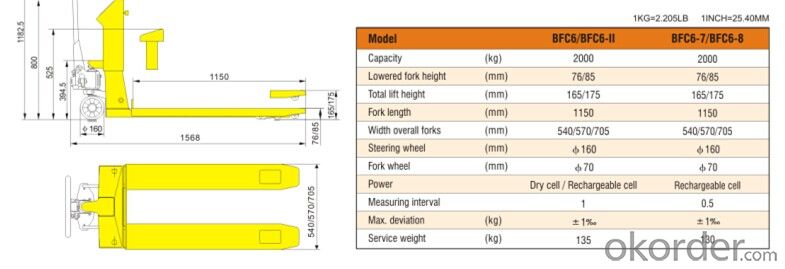

BFC6-7/BFC6-8 SCALE PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

From now on, CNBM team will continually adhered to company general policy “Stronger R&D, Better Quality, More favorable products and Wider promotion” and CNBM Spirit “ Modest Innovation, Hardworking Kindness” integrate the advanced resources and make greater efforts to innovate. CNBM will continue the spirit of : aggressively innovate, dare to pioneer, with traditional marketing-orientation, establishing and preferring the sales service channels, and with Ecommerce second, promoting and improving the traditional marketing models.

- Q:The wear-resisting parts in the broken machine are mainly the direct contact with the material

- There are many different types of crusher and different performance. For example: the jaw is broken, the hammer is broken, the fight is broken, the cone is broken... It is. Wear-resisting material is different also, also need according to the material hardness, strength of the material that is broken, the choice is ok. Material: white iron, alloy white iron (high chromium cast iron), high manganese steel, alloy steel (high, medium, low carbon and alloy)... It is. Prices are different because of different materials. Otherwise "overqualified person" not to calculate, "small material big use" not only use not, also do not calculate.

- Q:What are the potential defects of the automated material handling system?

- Automatic material handling system is to point to a series of related equipment and device, used in a process or a logical action system, coordination, reasonably to control the movement, storage, or material. Be able to carry out the material handling system and the design and arrangement of the container. Positioning of enterprise material handling system is a complicated problem, due to the imbalance between eastern and western regions in economic development in our country, determines the diversity of enterprise material handling system, both reflect the material handling in today's world of advanced science and technology level, by unmanned automatic handling car, automatic solid warehouse, automated conveyor etc of unmanned conveying system, there are still is in the middle of the last century the raw material handling conveyor line, but no matter what level, one thing is common, namely the material handling system and enterprise economic conditions, the level of product quality, Labour, match the market competitiveness of products and so on situation, that is to say, no one of the best material handling system,

- Q:What is the rational and scientific classification of logistics facilities and equipment

- Generally be divided into logistics facilities and equipment, logistics equipment, logistics, warehouse facilities and equipment, logistics transportation facilities and container handling equipment, logistics equipment, logistics, circulation unitized equipment, port logistics facilities and equipment processing equipment, automatic sorting equipment, information platform and equipment. Logistics infrastructure refers to the service function of a supply chain and some of the supply chain process, meet the need of logistics organization and management, which has the function of comprehensive or a single place or organization collectively, mainly including roads, railways, ports, airports, distribution center and network communication, etc. Logistics infrastructure includes warehousing, delivery facilities, and computing and information communication equipment.

- Q:The function of material handling

- Material handling USES all kinds of power and transport machinery to keep the material, such as count, punctually, safely, economically, and to the designated place. It is closely related to the choice of site selection and professional cooperation in the outside material handling machinery factory.

- Q:There are three things to do when the material is stacked up and down

- Fire prevention, waterproof, and do not exceed the limit.I hope my answer will help you.

- Q:What is the proof of working in mechanical design?

- Outline first Ⅲ part, is to the qualification examination examination form, time, attention, and the structure of test paper, test question distribution, topic topic quantity, and degree of difficulty of related regulations and instructions.

- Q:The principle of material handling

- Planning principles: plan all material handling and storage activities to achieve maximum overall operational efficiency. 2, the principle of system, to integrate various handling activities and suppliers, purchase, storage, production, testing, packaging, storage management, shipping, transportation, and the customer's operating system as a whole.

- Q:What is the carrying equipment of the container cargo

- Shockproof and vacuum packaging, equipment hoisting, lower layer, translation, adjustment level, container (container), import crane, forklift professional service.

- Q:The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q:Material handling system in the factory

- The machinery factory's internal logistics system involves the production plan, process flow, moving operation, warehouse management, information system and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BFC6-7/BFC6-8 SCALE PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products