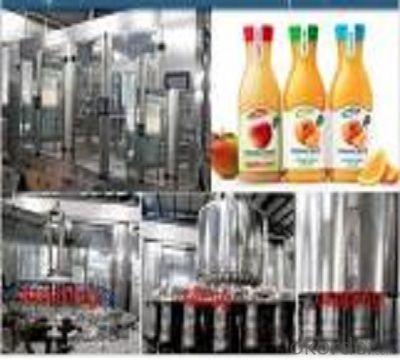

Beverage Production Line for bottle use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Description

1)The machine is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic. The machine is used in filling juices, mineral water and purified water in bottles made of polyester and plastics.

2)The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

3)The filling operation is faster and more stablebecause the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machines of the same specifications. The advanced OMRONprogrammed controller (PLC) is adopted to control the machine to run automatically while a transducer is used in the bottle -entering chains to adjust speeds and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably.

4)It is convenient tooperate with higher automation because every part of the machine is inspected to run with photo electricity, On the bases, the filling parts of the machine can be changed into filling methods of lower vacuum.

2.Main Features

Packaging & Delivery

Packaging Details:standard worthy wooden cases

Delivery Detail:30 working days

Company Management

Our company Our company has different department to finish different things,the sales in our company has been trained about the machines ,they are professional to help you.

Production Capacity

We can produce 10 complete lines ,30 machines per month.

3.Images

4.Specification

The filling operation is faster and more stablebecause the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machines of the same specifications. The advanced OMRON programmed controller (PLC) is adopted to control the machine to run automatically while a transducer is used in the bottle -entering chains to adjust speeds and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably.

It is convenient tooperate with higher automation because every part of the machine is inspected to run with photo electricity, On the bases, the filling parts of the machine can be changed into filling methods of lower vacuum.

Quality Control

We have the single quality department,that make sure the material of the raw materials is good,and ensure the machine running smoothly.

Designed and Developed

According to the customer's requirements,and the beverage industry's development, The designing department design the most suitable machine for different area.The designing department make our company the leader of the beverage packing machine manufacture.

Export Market

Our machine has been sold to more than 40 countries,almost of the customers are satisfied with the machines and our service.

- Q:What is the delay time of the packer's cross sealing?

- You can debug it yourself, set up a parameter, such as a delay of 1 second or a few seconds, look at the action of sealing, you know what time it is.

- Q:What are the main functions of packaging machinery and equipment?

- Such as cleaning, stacking and disassembly. In addition, also includes the measurement or the package seal etc.

- Q:What are the packaging machines that use temperature control watches?

- Such as shrink machine, vertical packaging machine, pillow type packaging machine, continuous sealing machine,

- Q:Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

- Q:What are the structures of the packaging machinery?

- Is a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on.

- Q:What does the mechanical equipment include?

- Rail aligning machine, rail straightening machine, grinding machineSlag shaping machine for track flat car internal combustion engine

- Q:Where is secondhand corrugated paper packaging machinery available?

- Carton factory and general production enterprise is different,General business is to face direct consumers, the need for their own sales network, sales staff, sales means......And carton factory as long as accurate manufacturers, show their means, get business.Maybe you walked into a food factory, an electrical factory, a furniture factory, a toy factory...... Can be your client.With business, but also to choose their own plant.Cartons are flammable and afraid of water. This is the disadvantage of cartons. If handled properly, there will be no problem.Site is best to avoid low-lying and rainy lots of water, the cardboard should not be piled directly on the ground, the bracket is a good choice.No smoking in the factory area, no open fire, and good fire fighting equipment, so as to ensure the safety of production.The size of the initial plant is best to be 500 square meters, or larger, smaller.

- Q:What is a packaging machine?

- Packaging machinery refers to the machinery that can complete all or part of the product and commodity packaging process. The packaging process includes filling, wrapping, sealing and other main processes

- Q:The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q:Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Beverage Production Line for bottle use

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords