Best Selling Cookware Deep Drawing 1100 Aluminium Circle for Utensils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

1100-H14-DIAMOND EMBOSSED ALUMINUM SHEET

Thickness:1.2mm---4mm,

width:1000mm---1500mm

Product code: 618 a - 33 y titanium matte aluminum plate

Technical parameters

Aluminum alloy/material: 1100

Tensile strength N/was: 115-125

The yield strength of N/was: 150-150

Elongation % : 3 or more

Rainbow degrees: no

Process: light oxidation process

Product description: surface "colored metal silken face" as the main characteristics of the product, completely metal texture, color variety, products can be mild tensile and bending.

Product use: can be used to directly shape stamping, screen printing, thermal transfer two composite process, etc.Used in architectural decoration, household appliances, switch panel, auto parts, lamps lighting, electronic hardware and other industries.

Supply scope of coil or sheet

Mm thickness specification: 0.4 1

Maximum width mm: 1250

The tolerance range

Mm thickness: 0.02 mm

The width of the mm: 2 -

Mm length: 2 -

Actual weight kg: plus or minus 2

Protective film

Protective film on the surface of the aluminum quality assurance period for six months, aluminum is kept dry and ventilated, avoid heat and direct sunlight.If the aluminium material stored in high temperature or direct sunlight can cause protective film, or unable to tear in addition to wait for a phenomenon.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

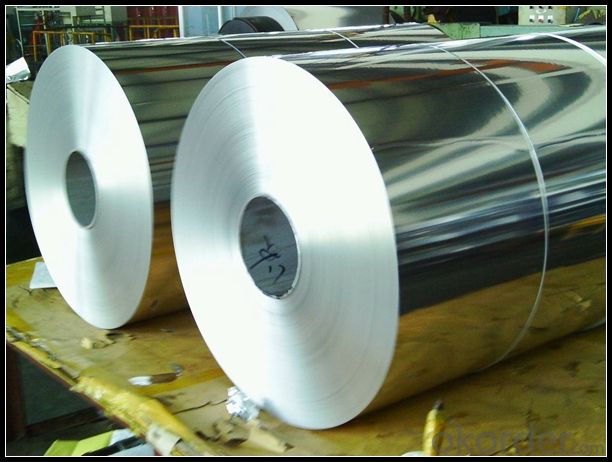

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q:what's the oxidation method of positive pole on the surface of aluminum sheet?

- Do chemical polishing again, oxidation time is about 40 – 90 minutes, after finishing all of these, you can conduct positive pole oxidation, choose sulfuric acid solution in normal situation, pretreatment is very important in the whole process, take stereo as negative pole, firstly, use the solution mixed of carbonate-bicarbonate and detergent to heat and clean its surface, pretreat the aluminum sheet, dyeing according to requirement after oxidation, then remove the oxide film with oxide film removal solution, place aluminum sheet on the positive pole, finally closing it in the boiling water for about 15 minutes.

- Q:i've been looking at stove top espresso coffee makers and they are all made of either aluminum or stainless steel. so i wonder is one metal any better than the other as far as coffee makers go? i thought before i actually buy one i'd like to hear from you - do you have a stove top espresso maker? what metal is it and what do you think of it? looking forward to reading your thoughts - thanks everyone!cheers!

- For general cookware both metals have different attributes. Aluminum conducts heat better and therefore pots and pans heat up more evenly. Stainless steel on the other hand has a nicer look and doesn't discolor and oxidize the way aluminum might, and it cleans up better. For an espresso maker you really don't need even heating since you are only heating water in a really small area. Therefore you should go with stainless steel.

- Q:What are the different edge treatments available for aluminum sheets?

- There are several different edge treatments available for aluminum sheets, each serving a specific purpose or aesthetic preference. Some common edge treatments for aluminum sheets include: 1. Mill Finish: This is the standard edge treatment for aluminum sheets, where the raw edges of the sheet are left untreated after the manufacturing process. It has a smooth, unfinished appearance. 2. Trimmed: In this treatment, the rough edges of the aluminum sheet are trimmed and smoothed to create a clean, rounded edge. This is often done using shearing or milling techniques. 3. Deburred: Deburring is a process where the sharp edges of the aluminum sheet are removed, typically by filing or sanding, to eliminate any potential hazards or sharpness. It results in a smoother, safer edge. 4. Rolled: Rolled edges are created by bending the edges of the aluminum sheet inward or outward. This treatment provides additional strength and rigidity to the sheet and can also enhance its appearance. 5. Anodized: Anodizing is a surface treatment that involves immersing the aluminum sheet in an electrolytic solution and applying an electric current. This creates a protective oxide layer on the surface, which can be colored to provide an attractive and durable edge finish. 6. Powder Coated: Powder coating involves applying a dry powder paint onto the aluminum sheet, which is then heated to form a hard, protective finish. This treatment can be used to create a variety of colors and textures for the edge. 7. Brushed: Brushed finishes are achieved by brushing the aluminum sheet with abrasive materials, creating a textured and visually appealing edge. This treatment is often used for decorative purposes. 8. Polished: Polishing involves buffing the aluminum sheet to create a smooth, reflective surface. This treatment is commonly used for architectural and decorative applications to enhance the appearance of the edge. These are just a few examples of the various edge treatments available for aluminum sheets. The choice of treatment depends on factors such as the intended use, desired aesthetics, and functional requirements of the aluminum sheet.

- Q:Can aluminum plates be welded with stainless steel or iron nuts?

- Upstairs is quite right! Even with brazing, it's hard to operate without experience

- Q:Are 101 aluminum sheets suitable for cryogenic applications?

- No, 101 aluminum sheets are not suitable for cryogenic applications.

- Q:What is the typical creep resistance of aluminum sheets?

- The typical creep resistance of aluminum sheets varies depending on the specific alloy and temper. Aluminum alloys typically have good creep resistance compared to other metals, especially at lower temperatures. However, the creep resistance of aluminum decreases significantly at higher temperatures. Aluminum sheets with higher alloying elements like copper, magnesium, or zinc tend to have better creep resistance than pure aluminum. Additionally, heat treatment processes such as cold rolling, annealing, or precipitation hardening can enhance the creep resistance of aluminum sheets. In general, aluminum sheets are known for their relatively low creep rates, making them suitable for various applications that require good dimensional stability over extended periods. However, it is important to note that the exact creep resistance of aluminum sheets can vary depending on the specific composition, processing, and operating conditions. Therefore, it is advisable to consult material specifications or conduct specific tests to determine the creep resistance of a particular aluminum sheet.

- Q:Which is good, aluminum curtain wall?

- Aluminum veneer manufacturers preferred Beijing Jinsheng Aluminium Industry Co. Ltd., it is very important to choose a single aluminum plate manufacturers, Beijing Jinsheng Aluminium Industry Co. Ltd is a professional manufacturer of aluminum veneer, advanced CNC equipment, first-class fluorocarbon spraying line, is your trusted manufacturer of aluminum veneer, aluminum veneer of large manufacturers, advanced technology, advanced technology and to undertake all types of single aluminum plate engineering, quality assurance, price concessions.

- Q:Can aluminum sheet be used for aircraft skin panels?

- Yes, aluminum sheet can indeed be used for aircraft skin panels.

- Q:Can the aluminum sheets be used for manufacturing medical equipment?

- Yes, aluminum sheets can be used for manufacturing medical equipment. Aluminum is a versatile and widely used material in various industries, including healthcare. It has several properties that make it suitable for medical equipment manufacturing. Firstly, aluminum is lightweight yet durable, which is beneficial for portable medical devices. It allows for easier handling and transportation of equipment, especially for healthcare professionals who may need to move them frequently. Secondly, aluminum has excellent corrosion resistance, making it suitable for medical applications where cleanliness and hygiene are crucial. It can withstand disinfection processes without deteriorating, ensuring the longevity of the equipment. Additionally, aluminum can be easily sterilized, which is essential for medical equipment. It can withstand high-temperature sterilization methods, such as autoclaving, without any adverse effects on its structural integrity. Moreover, aluminum is an excellent conductor of heat and electricity. This property is advantageous for medical equipment that requires efficient heat dissipation or electrical conductivity, such as surgical instruments or diagnostic tools. Furthermore, aluminum is a non-toxic material, making it safe for medical use. It does not leach harmful substances, ensuring that it does not pose any health risks to patients or healthcare professionals. In conclusion, aluminum sheets can indeed be used for manufacturing medical equipment due to their lightweight, durability, corrosion resistance, sterilization capabilities, thermal and electrical conductivity, and non-toxic nature. These properties make aluminum a suitable choice for various medical applications, contributing to the advancement of healthcare technology.

- Q:Are aluminum sheets suitable for electrical bus bars?

- Certain applications may find aluminum sheets suitable for use in electrical bus bars. Aluminum possesses several properties that make it a viable choice for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in situations where weight reduction is crucial. Furthermore, aluminum exhibits good electrical conductivity, although it falls short of copper in terms of conductivity. Nevertheless, aluminum bus bars can still handle high electrical currents and are commonly employed in power distribution systems. However, one drawback of aluminum bus bars is their higher resistance compared to copper bus bars. Consequently, they have a tendency to generate more heat, particularly under heavy current loads. To address this issue, aluminum bus bars are often designed with larger cross-sectional areas to minimize resistance and dissipate heat more effectively. Another challenge associated with aluminum bus bars is their vulnerability to oxidation and corrosion. This concern can be tackled by applying protective coatings or utilizing alloys that offer superior corrosion resistance. Additionally, it is crucial to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In conclusion, aluminum sheets can serve as suitable materials for electrical bus bars, particularly in scenarios where weight reduction is a priority. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Best Selling Cookware Deep Drawing 1100 Aluminium Circle for Utensils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords