Best Seller Color Coated Sheet/Corrugated Roofing Sheets/Al-Zn Galvanized Steel Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Application of Best Seller Color Coated Sheet/Corrugated Roofing Sheets:

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

2.Features of Best Seller Color Coated Sheet/Corrugated Roofing Sheets:

* uses hot dip galvanized steel sheet as the base material.

* zinc layer protection, dope on the zinc layer can cover and protect the steel base from corrosion.

* color coated sheet is light, beautiful and has good anti-erosion performancevanized steel coil.

* As a rich experience manufacturer, we provide quality product, competitive price and reliable after-sales service.

3.Surface Finish of Best Seller Color Coated Sheet/Corrugated Roofing Sheets :

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

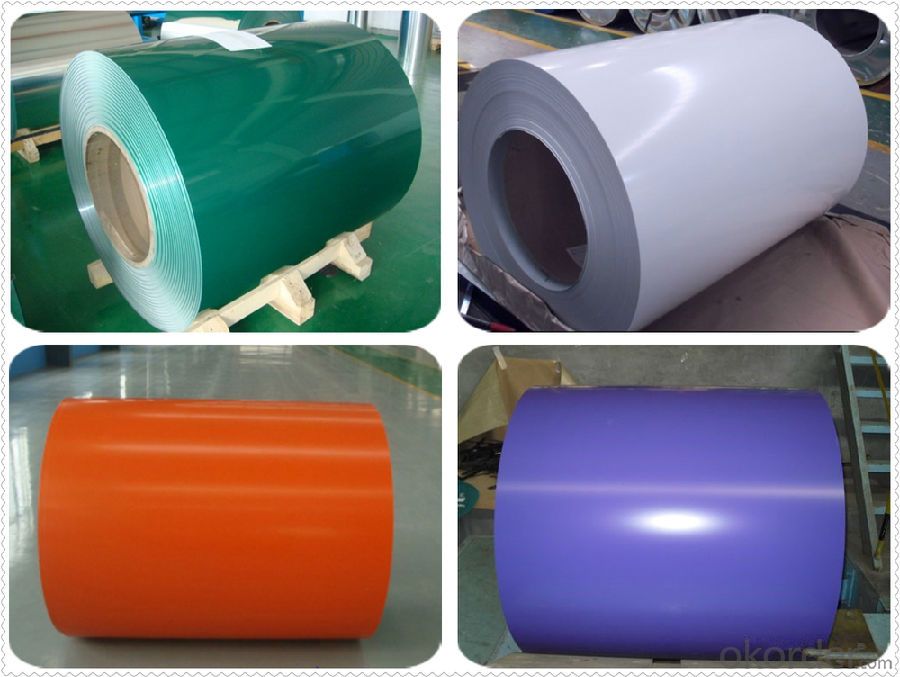

4.Best Seller Color Coated Sheet/Corrugated Roofing Sheets image:

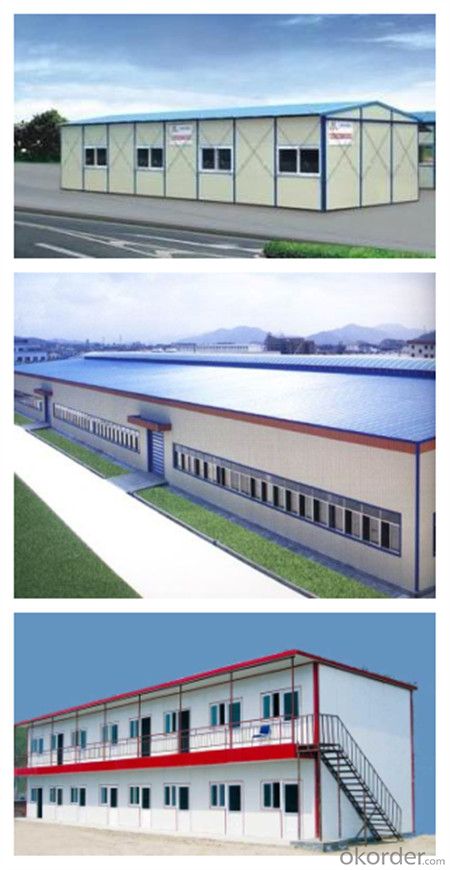

5. APPLICATIONS:

6. PROUDUCTION LINES:

7.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of color steel coils,is one of the large-scale professional investment steel production bases in China. Annually more than 8000 tons Precision Steel coils to be exported for more than 60 countries.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 10 to 15 working days can be served.

- Q:I am thinking about getting a cold steel tilite or a kershaw leek or possibly a buck sirus. If you have had any experience with these knives please give it to me. thanks

- Cold Steel uses an incredible quality of metal. If you want very durable go with that. The benefit to Kershaw is they make better folders. Fixed blade--go with Cold Steel. Folder, go with Kershaw. I get all my knives from the guys below, they have free shipping and really good prices.

- Q:What are the quality control measures for steel coils?

- Quality control measures for steel coils typically include various inspections and tests to ensure that the coils meet the required standards and specifications. These measures often involve visual inspections to identify any surface defects or irregularities, such as cracks, dents, or scratches. Additionally, dimensional checks are performed to verify the coil's size, shape, and weight. Other quality control measures may involve conducting mechanical tests, such as tensile strength and hardness tests, to assess the strength and durability of the steel coils. Overall, these measures aim to guarantee that the steel coils are of high quality and suitable for their intended applications.

- Q:Can steel coils be stored in unheated warehouses?

- Yes, steel coils can be stored in unheated warehouses as long as proper precautions are taken to prevent moisture and corrosion.

- Q:How do steel coils perform in extreme weather conditions?

- Steel coils are highly durable and resistant to extreme weather conditions. They can withstand intense heat, freezing temperatures, heavy rain, and strong winds without losing their structural integrity or performance.

- Q:What are the different types of steel coil packaging machines?

- There are several different types of steel coil packaging machines available in the market. These machines are designed to efficiently and effectively package steel coils for storage, transportation, or distribution. Some of the different types of steel coil packaging machines include: 1. Automatic steel coil packaging machine: This type of machine is fully automated and can handle high-volume packaging requirements. It uses advanced technology to wrap the steel coils with a protective layer of film or paper. The machine can also apply strapping or stretch film to secure the coils during transportation. 2. Semi-automatic steel coil packaging machine: This machine requires some manual intervention to load and unload the steel coils. It is suitable for medium to high-volume packaging needs and offers a good balance between automation and cost-effectiveness. The machine typically uses a combination of wrapping, strapping, and shrinking techniques to package the coils. 3. Vertical steel coil packaging machine: This type of machine is designed specifically for packaging vertical steel coils. It can wrap the coils with a layer of film or paper, and then apply strapping or stretch film to secure them. The vertical design allows for easy loading and unloading of the coils. 4. Horizontal steel coil packaging machine: This machine is ideal for packaging horizontal steel coils. It can wrap the coils with a protective layer of film or paper, and then apply strapping or stretch film to secure them. The horizontal design ensures easy loading and unloading of the coils. 5. Customized steel coil packaging machine: Some manufacturers offer customized packaging solutions based on specific requirements. These machines can be tailored to accommodate different coil sizes, shapes, and packaging materials. They are designed to provide maximum flexibility and efficiency in the packaging process. In summary, the different types of steel coil packaging machines include automatic, semi-automatic, vertical, horizontal, and customized machines. The choice of machine depends on factors such as packaging volume, coil orientation, and specific requirements of the steel coils being packaged.

- Q:How are steel coils used in the production of electrical appliances?

- Steel coils are used in the production of electrical appliances as the core component for electromagnets. These coils are wound around a metal core and when an electric current passes through them, they create a magnetic field which is essential for the functioning of various electrical components such as motors, transformers, and solenoids.

- Q:My uncle got me some new 'Nam style jungle boots at the px at Fort Worth JSB, and he told me that back in Vietnam, they used to issue guys steel sole boots, that had a sole reinforced with a steel plate, as punji stick d-fence. Is this true, it sounds logical, but I can't figure out how a steel plate in the sole would work. My uncle is kind of a BS'er, plus he wasn't even in Vietnam, much less the Infantry, much less combat, but he was in USAF at the time.

- Steel Sole Boots

- Q:Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials. Coating steel coils with heat-resistant materials provides protection against high temperatures and ensures the durability and longevity of the coils in various industrial applications.

- Q:The hard industrial steels. If there's a bunch, what's a rough average? Also, what is is measured in?

- Hrc Steel

- Q:What are the dimensions of steel coils?

- The dimensions of steel coils vary depending on factors such as the specific type of steel, the intended use, and industry standards. Generally, steel coils can range in width from a few inches to several feet, with thicknesses typically ranging from a fraction of an inch to several millimeters. The inner diameter of a steel coil can also vary, with common sizes being 20 inches and 24 inches. Ultimately, the dimensions of steel coils are determined by the specific needs and requirements of the end user.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Best Seller Color Coated Sheet/Corrugated Roofing Sheets/Al-Zn Galvanized Steel Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords