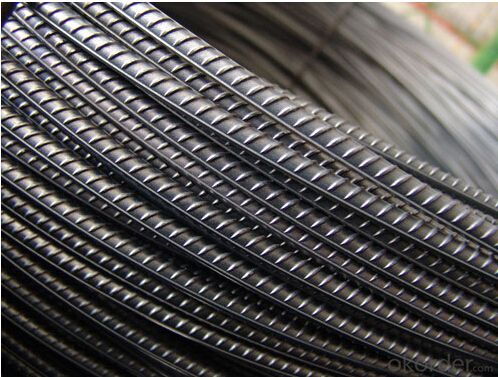

BEST QUALITY REBAR --STEEL PRODUCT FROM CHINA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | ASTM,BS,GB,KS,GB, BS ,KS, ASTM | Grade: | HRB400 | Diameter: | 6mm-40mm |

| Length: | 6-12meters,6m-12m | Place of Origin: | Hebei China (Mainland) | Brand Name: | Haixing |

| Model Number: | FHX | Application: | construction | color: | black |

| Package: | Within bundles | Thechique: | hot rolled |

Packaging & Delivery

| Packaging Detail: | MIill's export standard packing in bundles with wire rod as customer's requirement |

| Delivery Detail: | within 30 days |

Specifications

Certificates: CE & ISO9001:2000

Material: hrhrb400 ,hrb500, BS4449, ASTM A615, SD400

length:6-12

Size: 6mm-40mm

Product Description Material: HRB400,HRB500, BS4449,ASTM A615 GR40/60, SD400 usuage: building and construction |

- Q:What is the standard length of steel rebars?

- The standard length of steel rebars varies depending on the region and the specific requirements of the project. In the United States, for example, the standard length of steel rebars is commonly 20 feet or 6.1 meters. However, it is important to note that rebars can be cut and customized to different lengths as needed for a particular construction project. Additionally, in some countries or regions, rebars may be available in different standard lengths based on local construction practices and regulations. Therefore, it is essential to consult local codes and specifications to determine the standard length of steel rebars for a specific project.

- Q:What are the common mistakes to avoid while using steel rebars?

- Some common mistakes to avoid while using steel rebars include improper placement and spacing, insufficient concrete cover, using rusty or damaged rebars, improper anchoring or tying, and neglecting to clean and prepare the rebars before installation.

- Q:Are steel rebars prone to bending or warping?

- Steel rebars are not generally prone to bending or warping under normal conditions. Steel rebars are designed to have high tensile strength and are commonly used in construction projects to reinforce concrete structures. They are made from strong and durable materials such as carbon steel, which provides them with the ability to withstand heavy loads and resist deformation. However, it is important to note that external factors such as excessive heat or improper handling during transportation and storage can potentially cause rebars to bend or warp. Exposing steel rebars to high temperatures can cause them to lose their structural integrity and become more susceptible to bending or warping. Similarly, mishandling or poor storage practices, such as stacking them unevenly or placing heavy objects on top of them, can lead to deformation. To ensure the structural integrity of steel rebars, it is crucial to follow proper handling and storage guidelines, as well as ensure that they are used within the specified load limits. Additionally, it is essential to consider the environmental conditions in which the rebars will be utilized to minimize the risk of bending or warping.

- Q:How are steel rebars cut and shaped on-site?

- Steel rebars are commonly cut and shaped on-site using various tools and techniques. The process typically involves the following steps: 1. Measurement: The rebars are first measured according to the required length and shape. This is done by using measuring tapes, rulers, or other measuring devices. 2. Marking: Once the measurements are taken, the rebars are marked at the appropriate points using chalk or a marker. These marks serve as guidelines for cutting and shaping the rebars accurately. 3. Cutting: The rebars are then cut along the marked lines using mechanical or hydraulic cutting tools. Some commonly used tools for cutting rebars include rebar cutters, angle grinders with cutting discs, or portable band saws. These tools are specifically designed to handle the high strength of steel rebars and ensure clean and precise cuts. 4. Shaping: After the rebars are cut to the desired lengths, they can be further shaped as needed. This shaping process involves bending the rebars into specific angles or curves. Manual rebar benders or electric rebar bending machines are commonly used for this purpose. These tools allow for accurate shaping of the rebars, ensuring they fit the required structural design. 5. Tying: Once the rebars are cut and shaped, they are often tied together using wire or rebar tying machines. This tying process helps to secure the rebars in place and maintain the desired positioning within the concrete structure. It is important to note that the cutting and shaping of rebars on-site require skilled workers who are trained in handling the tools and following proper safety precautions. These workers must also have a good understanding of the structural requirements and be able to interpret construction drawings to accurately cut and shape the rebars according to the project specifications.

- Q:Are steel rebars suitable for use in foundation structures?

- Yes, steel rebars are suitable for use in foundation structures. Steel rebars, also known as reinforcing bars, are commonly used in concrete construction to provide strength and reinforcement to the structure. The use of steel rebars in foundation structures helps to increase the load-bearing capacity and durability of the foundation. Steel rebars are made from steel, which has high tensile strength and is resistant to corrosion, making it an ideal material for use in foundation structures. The rebars are placed in the concrete during construction, providing additional strength and preventing cracks or fractures in the foundation. They help to distribute the load evenly throughout the foundation, reducing the risk of settlement or failure. Furthermore, steel rebars can be easily customized to meet the specific requirements of the foundation structure. They come in various sizes, shapes, and grades, allowing for flexibility in design and construction. This versatility makes steel rebars suitable for use in different types of foundation structures, including residential, commercial, and industrial buildings. Overall, steel rebars are a reliable and cost-effective choice for reinforcing foundation structures. They enhance the structural integrity and longevity of the foundation, ensuring a solid and stable base for the entire building.

- Q:How do steel rebars prevent cracks in concrete?

- The reinforcement provided by steel rebars is essential for preventing cracks in concrete. These rebars increase the tensile strength of the concrete, which is weak in tension. While concrete can withstand compressive forces, it is susceptible to cracking when subjected to tension or pulling forces. When steel rebars are embedded in concrete, they function as a framework or skeleton that distributes the tensile forces evenly throughout the structure. As a result, the rebars absorb the tension, effectively preventing the concrete from cracking or failing under the applied load. In addition to absorbing tension, the rebars also control the size and width of any cracks that may occur. By confining the cracks to a limited area surrounding the rebars, they prevent the cracks from spreading throughout the entire concrete structure. Furthermore, the presence of rebars can even help prevent cracks from forming in the first place, as they reinforce the concrete and improve its overall durability. To summarize, steel rebars play a critical role in preventing cracks in concrete by increasing its tensile strength, absorbing tension, and controlling crack propagation. This reinforcement is vital in ensuring the structural integrity and longevity of concrete structures, effectively preventing potential failures and ensuring their safety.

- Q:What are the standards and specifications for steel rebars?

- International organizations such as ASTM and ISO primarily establish the standards and specifications for steel rebars, also known as reinforcing bars. These standards guarantee that steel rebars meet specific requirements for strength, durability, and dimensional accuracy. ASTM A615 is one of the most commonly used standards for steel rebars. It covers deformed and plain carbon-steel bars for concrete reinforcement. This standard sets the minimum yield strength, tensile strength, and elongation properties for various rebars grades, including Grade 40, Grade 60, and Grade 75. It also outlines the mechanical properties, chemical composition, and bending properties of rebars. Aside from ASTM A615, there are other standards that provide specifications for steel rebars. ASTM A706, for instance, focuses on low-alloy steel bars for concrete reinforcement. This standard ensures that rebars possess improved weldability and ductility to withstand seismic forces and other dynamic loads. ISO 15630 is another significant standard that addresses steel for concrete reinforcement. It provides specifications for hot-rolled and cold-worked steel bars, as well as welded fabric and lattice girders. ISO 15630 outlines the mechanical properties, chemical composition, and dimensional tolerances of rebars. Furthermore, regional or national organizations also establish their own standards for steel rebars. For instance, the BSI has developed the BS 4449 standard, which specifies the requirements for carbon steel rebars used in concrete reinforcement in the United Kingdom. Similarly, the ISI has set the IS 1786 standard for cold-twisted steel bars used in concrete reinforcement in India. In conclusion, the standards and specifications for steel rebars ensure that these construction materials possess the necessary strength, ductility, and other properties required for reinforcing concrete structures. By adhering to these standards, manufacturers, engineers, and construction professionals can ensure the safety and durability of reinforced concrete projects.

- Q:What is the role of steel rebars in preventing shrinkage cracks in concrete?

- The role of steel rebars in preventing shrinkage cracks in concrete is to provide reinforcement and increase the tensile strength of the concrete. As concrete shrinks during the drying and hardening process, it tends to crack. However, the presence of steel rebars within the concrete helps to distribute the tensile forces caused by shrinkage, reducing the likelihood of cracks forming and enhancing the overall durability and stability of the structure.

- Q:How do steel rebars prevent concrete structures from collapsing?

- Steel rebars prevent concrete structures from collapsing by providing reinforcement and strength to the concrete. Concrete is a strong material in compression, meaning it can withstand forces that push or squeeze it together. However, it is weak in tension, meaning it cannot withstand forces that pull it apart. When subjected to tensile forces, concrete can crack and ultimately fail. Steel rebars, or reinforcement bars, are typically placed within concrete structures to counteract these tensile forces and provide additional strength. The rebars are made of high-strength steel and are strategically positioned within the concrete to resist the tensile forces. When external forces, such as wind or seismic activity, act on a concrete structure, the rebars help distribute the load and resist the tension. As the concrete tries to pull apart, the rebars hold it together, preventing cracks from propagating and ensuring the structure remains intact. The rebars also improve the overall durability and longevity of the concrete structure. By reinforcing the concrete, the rebars help reduce the effects of shrinkage and thermal expansion, which can cause cracks over time. This results in a more stable and resilient structure that can better withstand various environmental and structural stresses. Overall, steel rebars play a critical role in preventing concrete structures from collapsing by providing the necessary reinforcement and strength to resist tensile forces. They enhance the structural integrity, durability, and safety of concrete structures, ensuring they can withstand the demands placed upon them and continue to serve their intended purpose for many years.

- Q:Are steel rebars resistant to chemical attacks?

- Steel rebars are generally resistant to chemical attacks, but their resistance can vary depending on the specific chemicals they are exposed to. Steel rebars are primarily made of carbon steel, which is known for its high strength and durability. Carbon steel has good resistance to many common chemicals, such as water, mild acids, and alkalis. However, certain chemicals can pose a threat to steel rebars and cause corrosion or deterioration. For example, strong acids, such as sulfuric acid or hydrochloric acid, can rapidly corrode steel rebars. Additionally, exposure to chlorides, such as those found in saltwater or deicing salts, can increase the risk of corrosion in steel rebars. To enhance the resistance of steel rebars to chemical attacks, various protective measures can be taken. One common method is to apply a protective coating, such as epoxy or zinc, on the rebars. This coating acts as a barrier between the steel and the chemicals, preventing direct contact and reducing the risk of corrosion. In summary, while steel rebars are generally resistant to chemical attacks, their resistance can be influenced by the specific chemicals they are exposed to. Proper protective measures can be taken to enhance their resistance and prolong their lifespan in environments where chemical exposure is a concern.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BEST QUALITY REBAR --STEEL PRODUCT FROM CHINA

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords